Manufacturing method of scale production of double electric layer capacitor

A technology for electric double-layer capacitors and manufacturing methods, applied in hybrid/electric double-layer capacitor manufacturing, capacitor manufacturing, electrolytic capacitors, etc., can solve the problems of limited number of cycle charging, short battery life, and inability to meet industrial scale production , to achieve the effect of low equivalent internal resistance and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

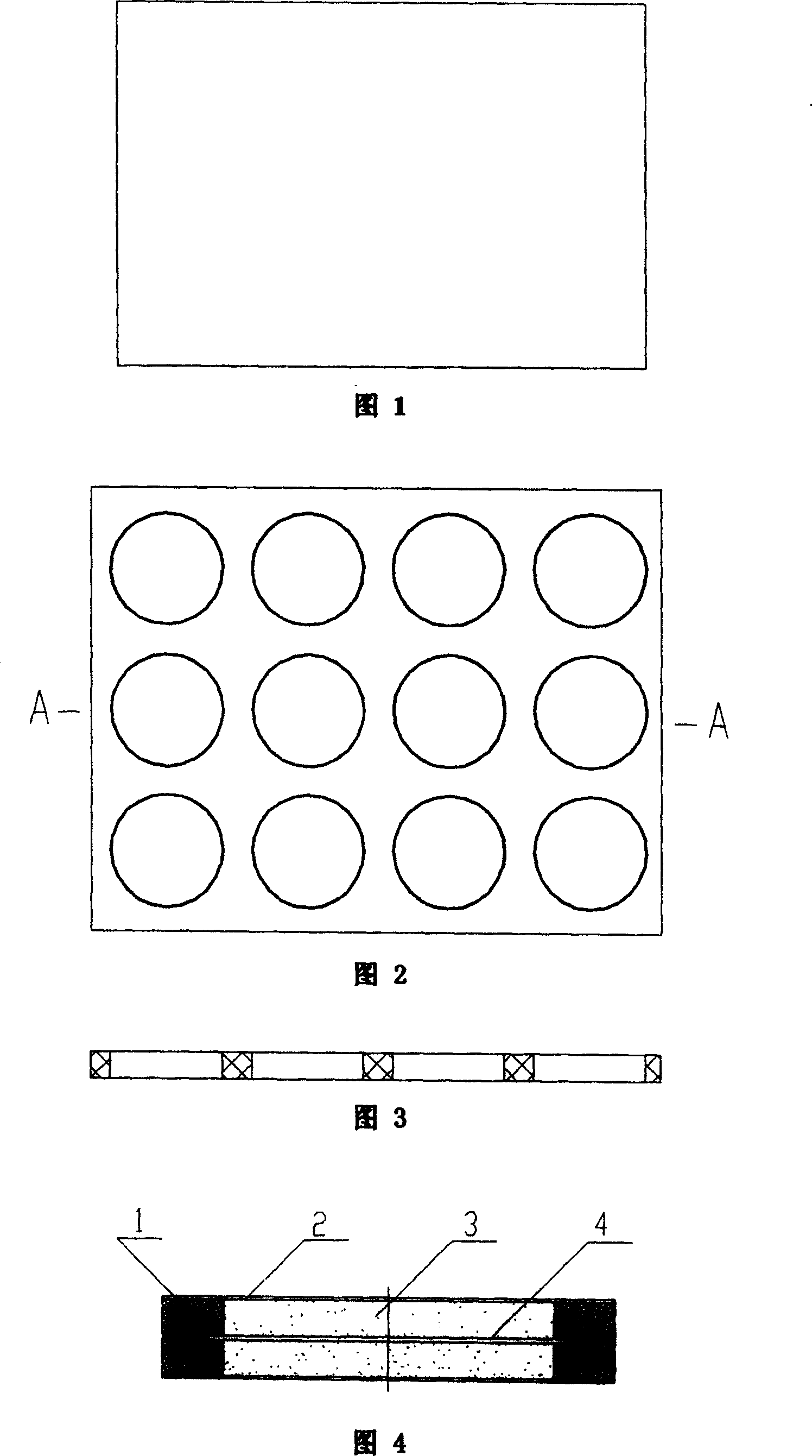

[0014] According to the accompanying drawings 1 and 2, the conductive rubber 2 and the insulating rubber 1 are respectively processed into sheets, and a plurality of corresponding porous electrode 3 holes are left on the insulating rubber 1 according to the position and shape rules of the capacitor porous electrodes, and then according to the conductive Rubber 2, insulating rubber 1, porous electrode 3, diaphragm 4, insulating rubber 1, porous electrode 3, and conductive rubber 2 are superimposed in sequence, wherein the porous electrode is superimposed on the reserved position of the insulating rubber. Then, a plurality of electric double layer capacitor cells are punched out at one time by mechanical punching, that is, the mass production of multiple cells is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com