Quenching apparatus for hollow structural component and quenching method

A quenching device and component technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of slow cooling, insufficient quenching, difficult to reach the quenching liquid, etc., and achieve less risk of deformation, sufficient quenching, and restrained cooling. uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] (constitute)

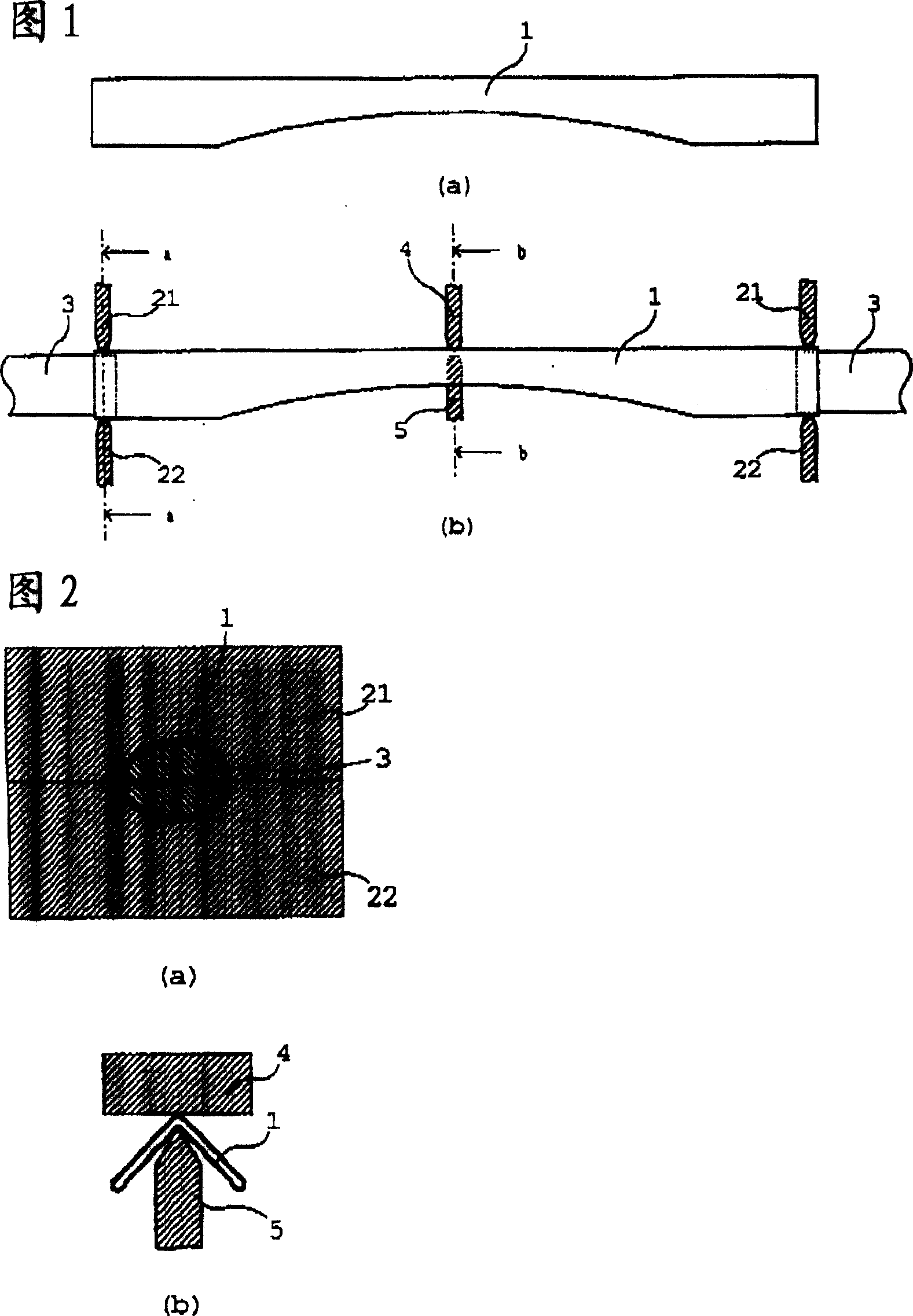

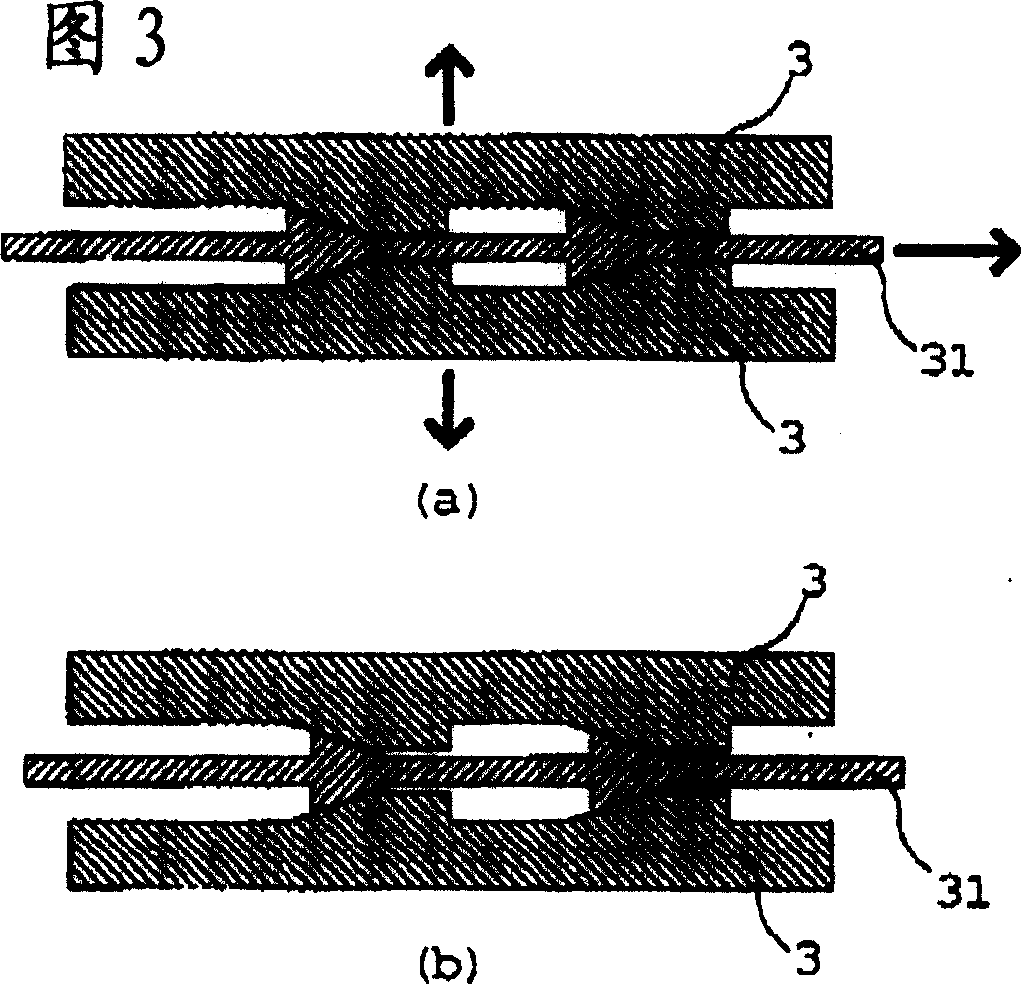

[0023] A quenching device for a hollow member according to the present invention includes an end restraint jig, a contact jig, and a cooling device. The hollow member which is the target of the device of the present invention is a member whose interior is hollow. In addition, it is a cylindrical member with both ends opened. In particular, elongated members are likely to be skewed during quenching, so it is preferable to perform quenching with this device.

[0024] The end restraint jig is a member that restrains the both ends of the hollow member and suppresses the inflow of cooling fluid from the both ends. The end constraining jigs include a set of internal constraining jigs having outer shapes substantially corresponding to shapes of inner peripheries of both end portions of the hollow member. When the shapes of the inner peripheries of both ends are different, the outer shape of the internal restraint jig is also set to a shape corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com