Strong selfpriming pump

A technology of self-priming pumps and centrifugal pumps, applied in the field of centrifugal pumps, which can solve the problems of large amount of maintenance and disassembly, complex overall structure, unfavorable serialization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

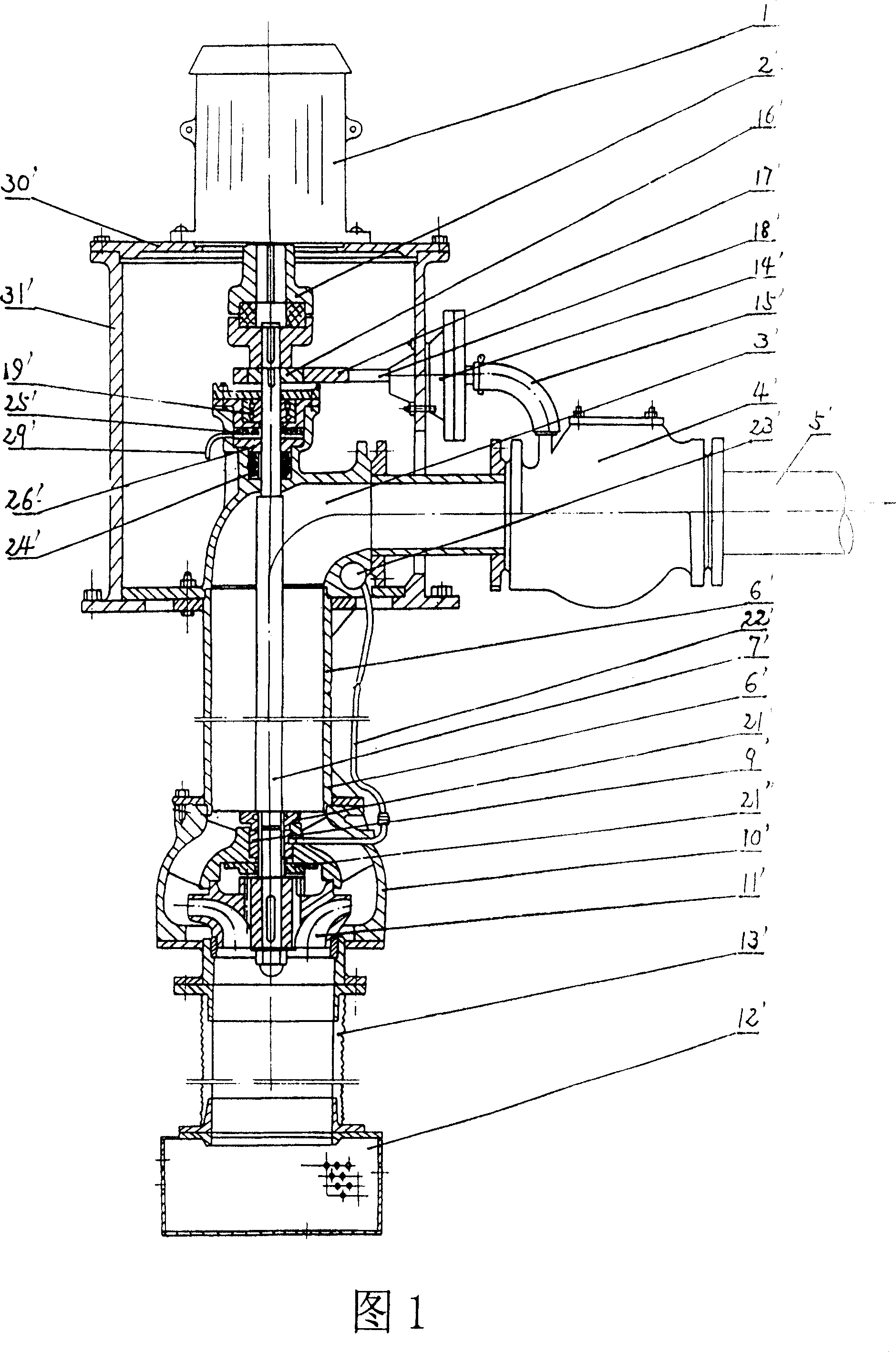

[0040] As shown in Figure 2, the strong self-priming pump that I have designed according to the above technical scheme consists of a suction device, a clutch device, a motor and a centrifugal pump that are easy to load and unload.

[0041] The structure of the suction device is the same as the suction device in ZL92209212.5. It includes: a pressure chamber body 11 provided with a one-way suction port 111, a pressure chamber body cover 12 provided with a one-way exhaust port, and A suction mechanism composed of an air hole 132 and an actuating body 13 of a membrane valve 131; a suction mechanism composed of a connecting rod 141, a shaft pin 142, a crank 143, a bearing 144 and an eccentric friction clutch sleeve 145 sleeved with the vertical upward shaft of the motor The transmission mechanism of the air mechanism.

[0042] The clutch device is composed of a clutch friction part and a clutch pressure part; the clutch friction part is composed of an eccentric friction clutch sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com