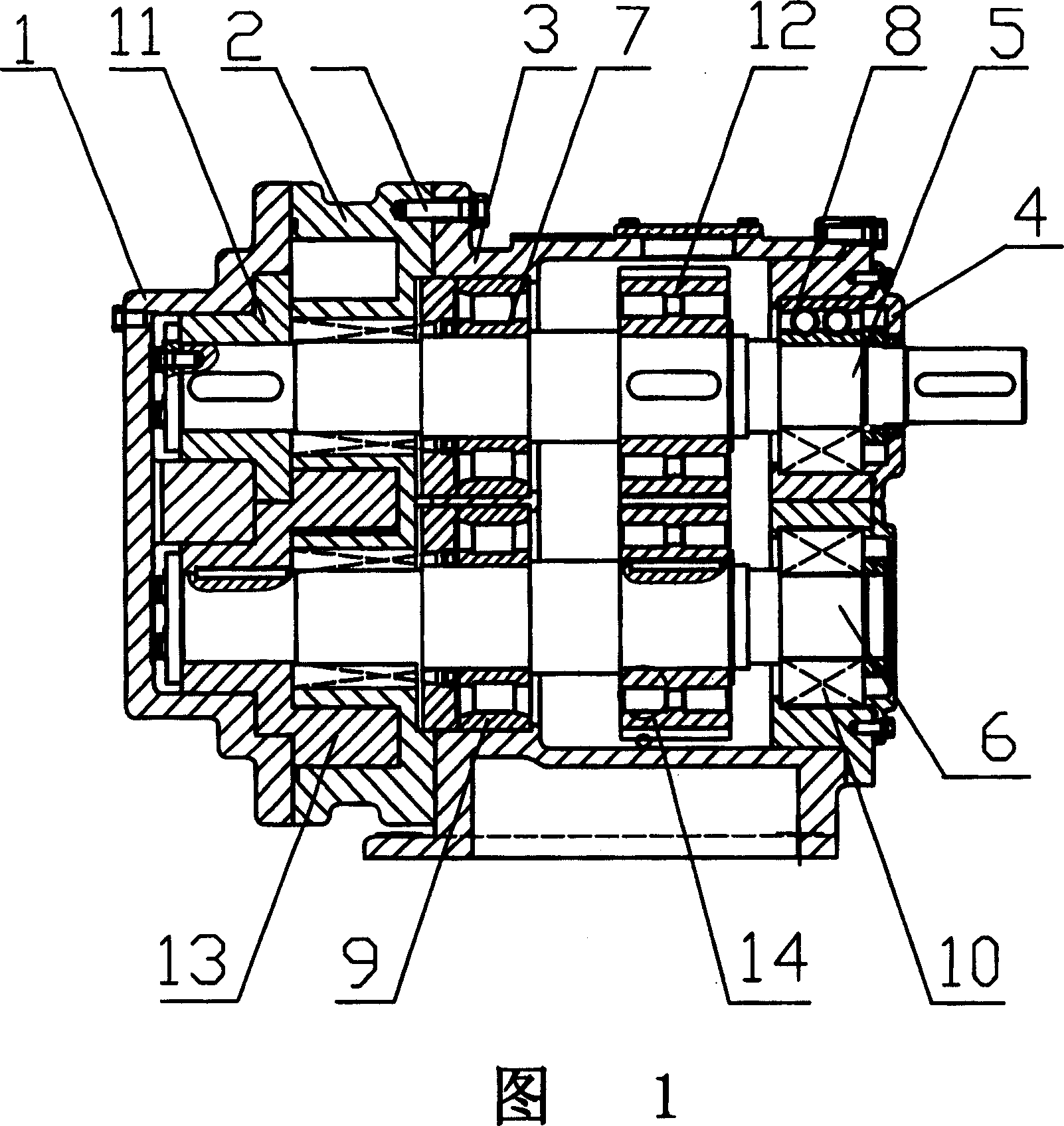

External circulation piston pump

A piston pump and external circulation technology, applied in the direction of rotary piston pumps, rotary piston machinery, pumps, etc., can solve the problems of performance degradation, affecting sealing effect, low discharge pressure, etc., to improve performance and efficiency, and avoid gaps Unevenness, the effect of narrowing the sealing gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

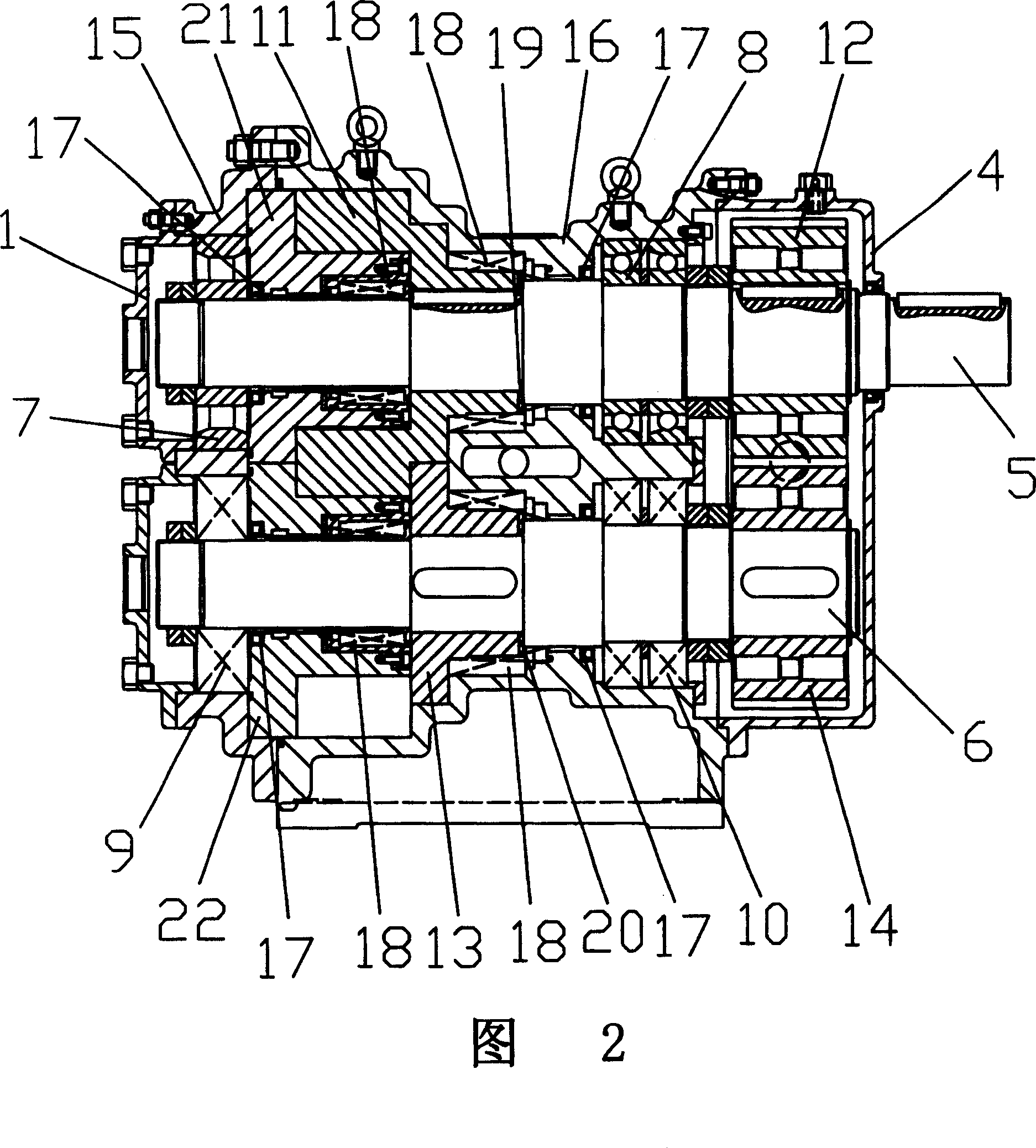

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Referring to Fig. 2, a kind of external circulation piston pump, comprises motor, speed reducer, pump body assembly, and described pump body assembly comprises the front end cover 1, middle cover 15 that connects successively, traditional pump body and box body Body 16 and rear end cover 4 integrated into one body. The middle sleeve 15 here can play the role of supporting other components and sealing the working cavity and the oil cavity. The body 16 is provided with a drive shaft 5 and a driven shaft 6, the output shaft of the motor is connected with the input shaft of the reducer through a coupling, and the output shaft of the reducer is connected with the reducer through a coupling. The driving shaft 5 of the pump body assembly is connected;

[0017] The drive shaft 5 is supported by the first bearing 7 and the second bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com