Swirl fluid machinery

A kind of fluid machinery and scroll technology, applied in the direction of rotary piston machinery, mechanical equipment, rotary piston pump, etc., can solve the problems of reduced compression efficiency and increased gap, so as to reduce power loss, improve strength and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

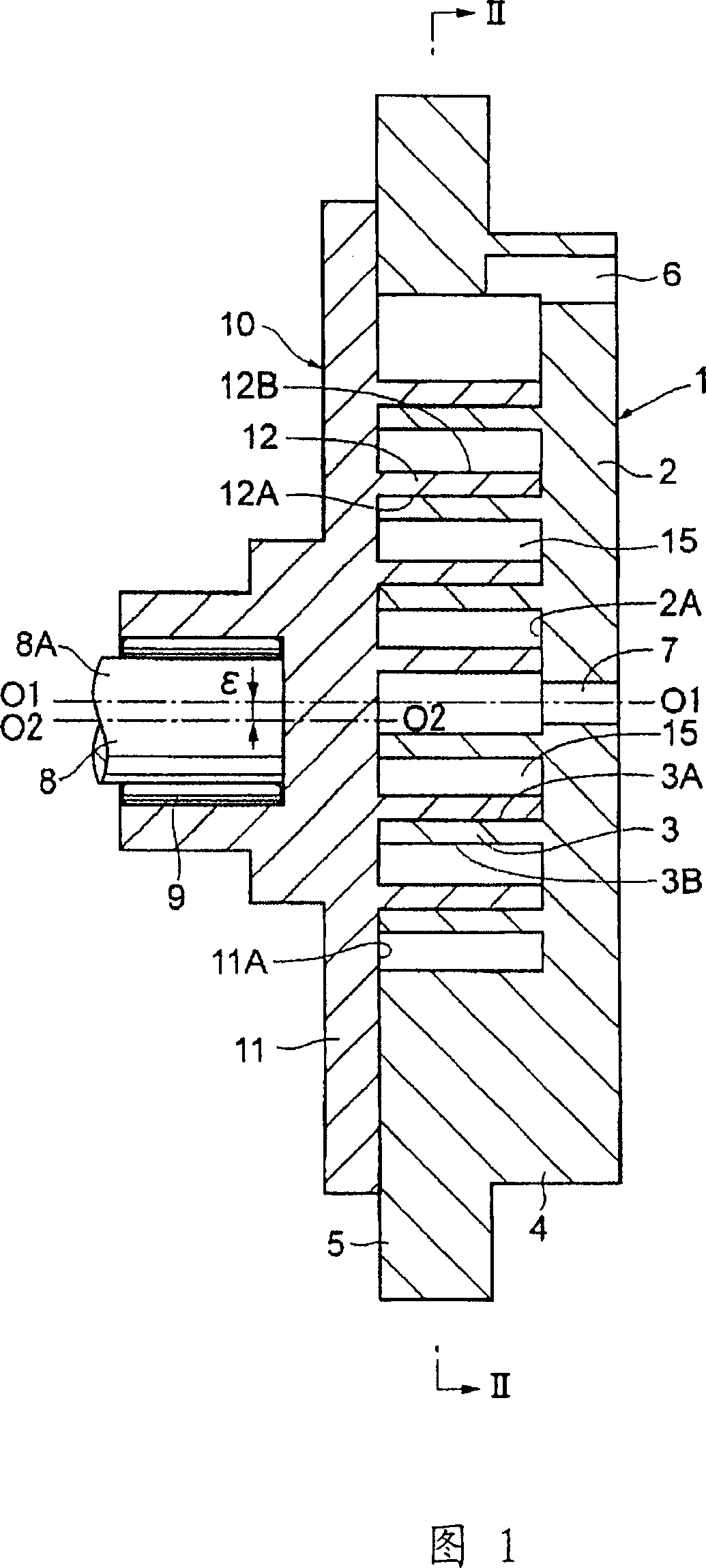

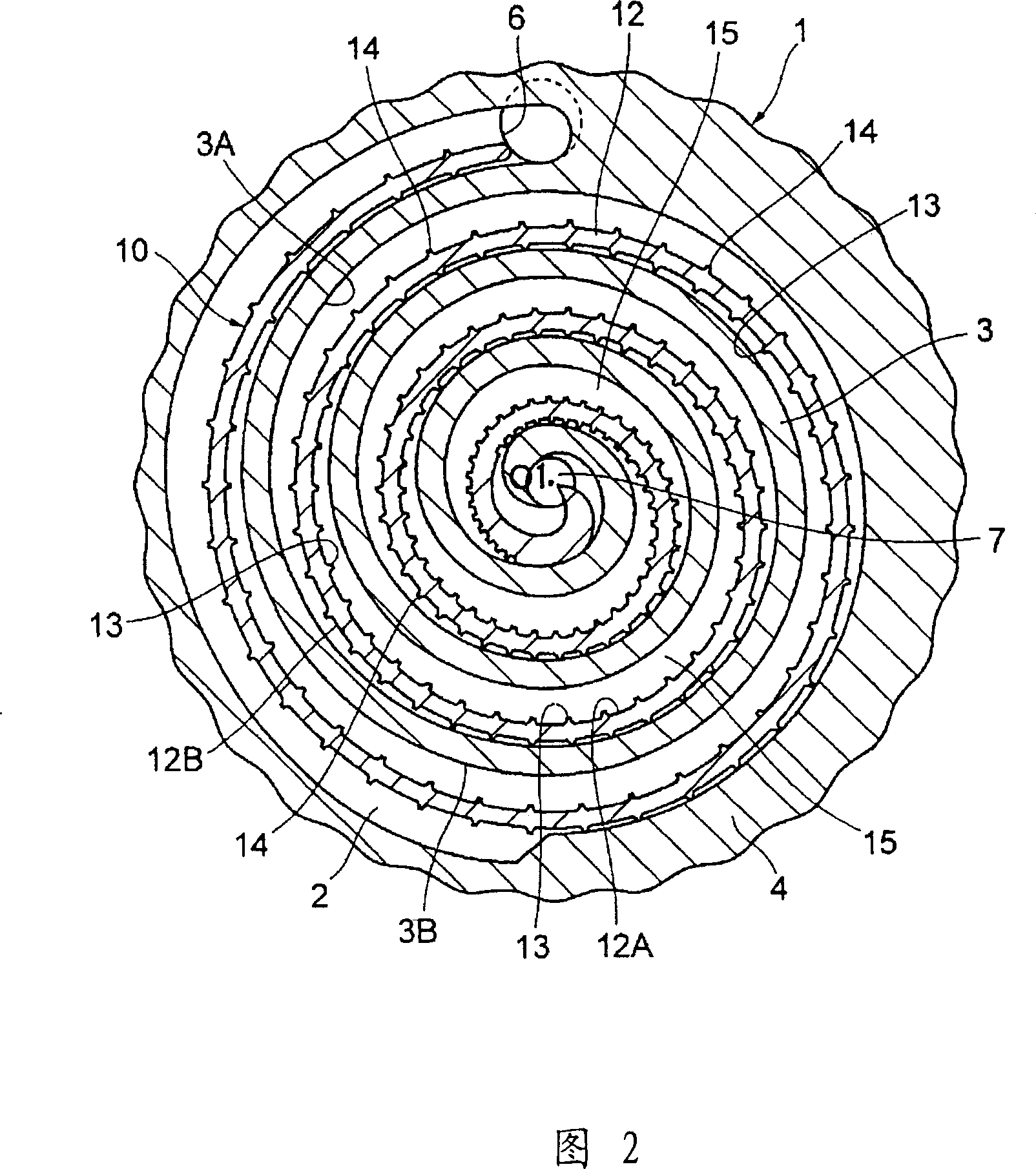

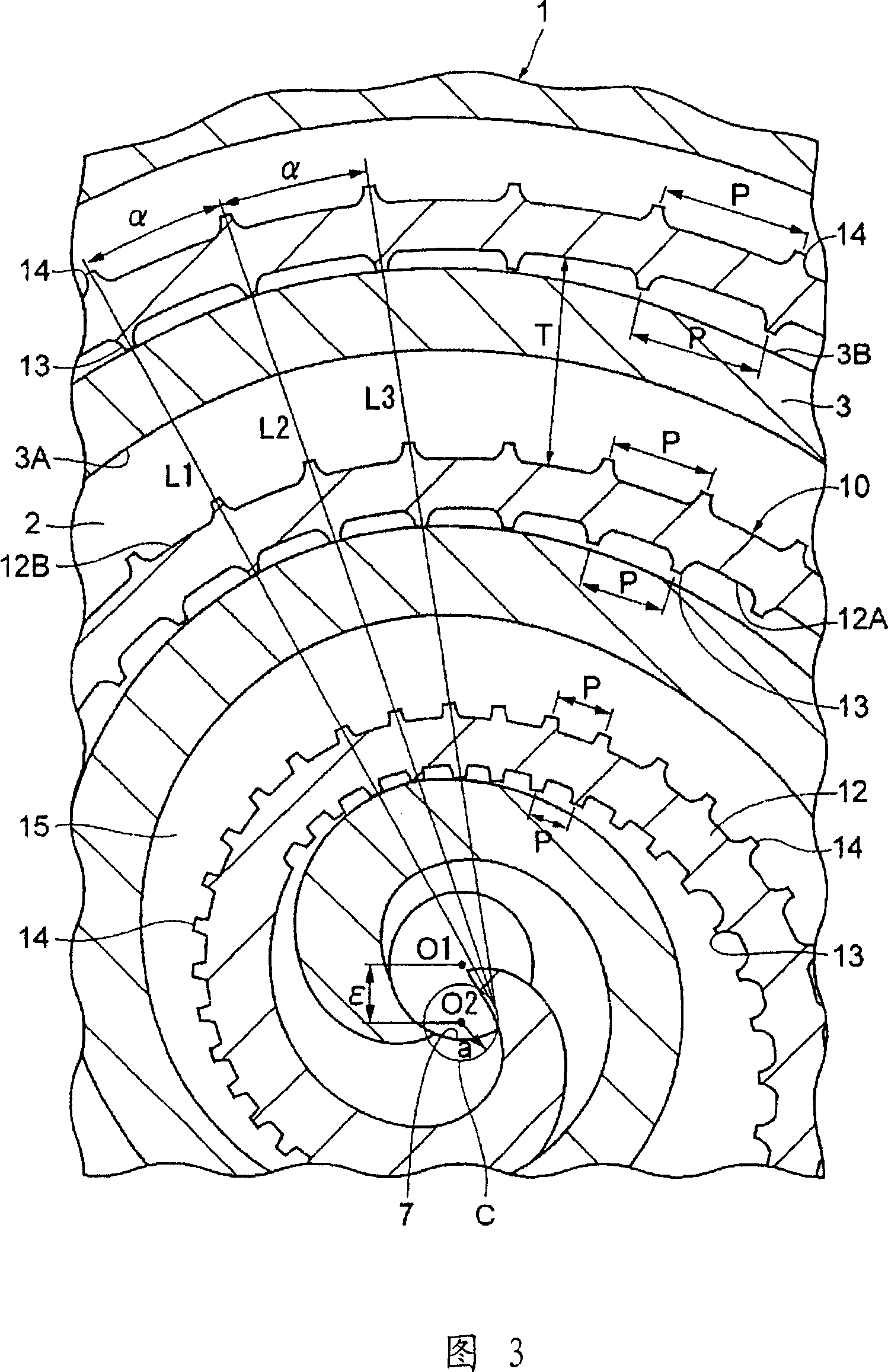

[0105] Hereinafter, a scroll-type fluid machine according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings, taking a scroll-type air compressor as an example.

[0106] Here, FIGS. 1 to 13 show a first embodiment, and in this embodiment, a configuration in which protrusions are provided on the orbiting scroll will be described as an example.

[0107] FIG. 1 shows a longitudinal sectional view of a scroll air compressor. In this FIG. 1, 1 is a fixed scroll body of the scroll air compressor; the fixed scroll body 1 is attached to a cylindrical casing (not shown) end of . In addition, the fixed scroll body 1 includes: an end plate 2 formed in a disc shape, the center of which is aligned with the axis 01-01 of the drive shaft 8 to be described later; The lap portion 3 ; the cylindrical portion 4 that surrounds the lap portion 3 and protrudes in the axial direction from the radial outer side of the end plate 2 ; and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com