Carbon brush wear sensor device of motor

A technology of sensing devices and motors, applied in the direction of circuits, current collectors, electrical components, etc., can solve problems such as blocking the optical path, alarm failure, hole blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

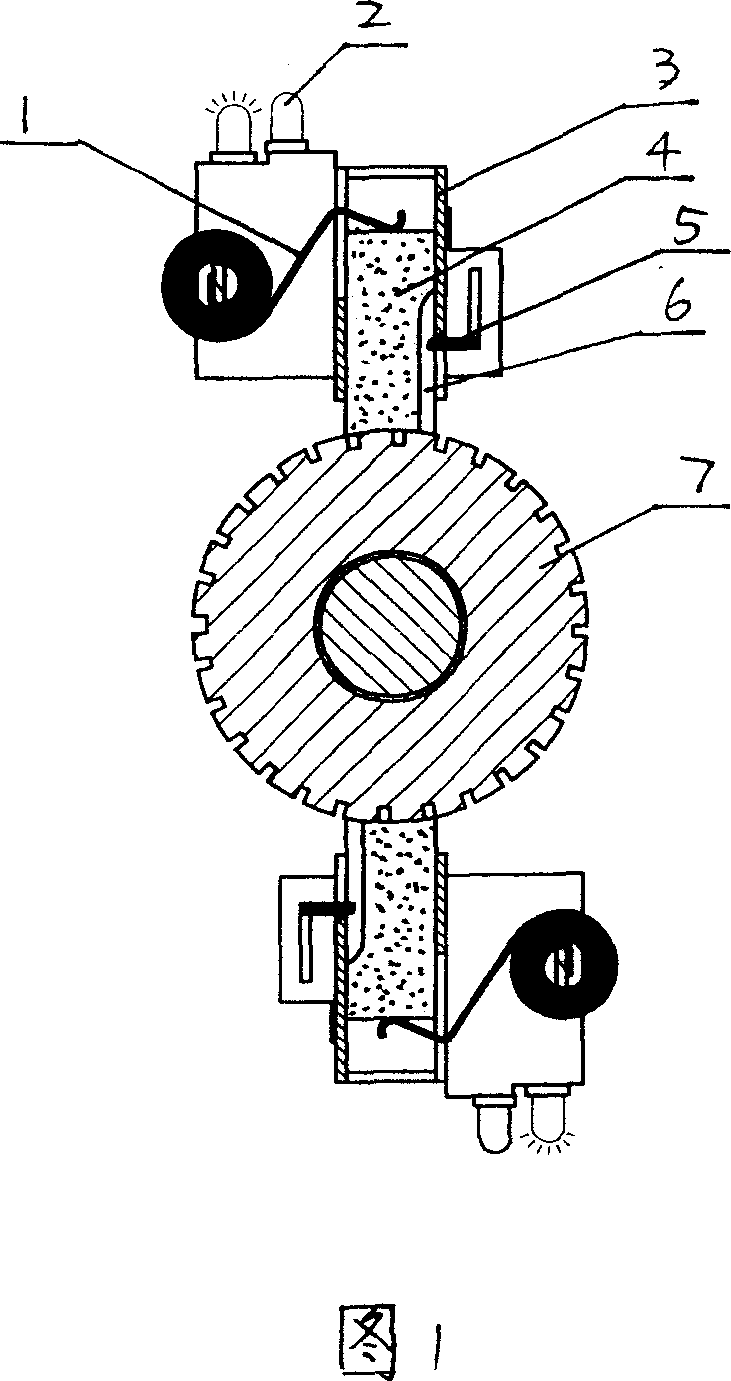

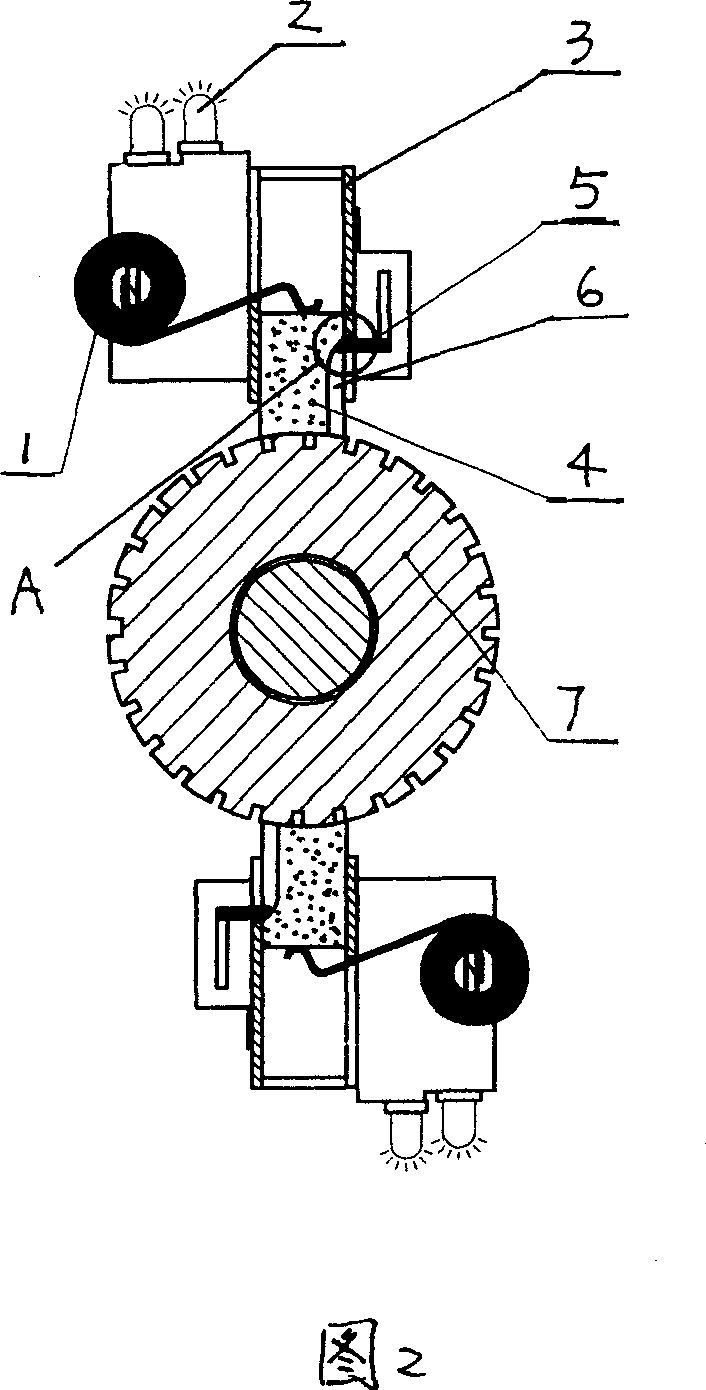

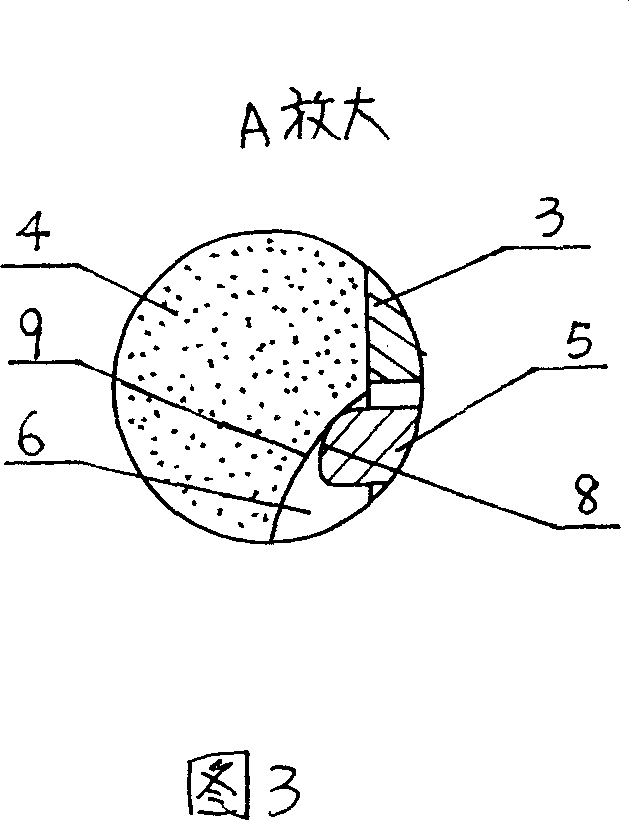

[0017] Embodiment 1 is that the surface of the carbon brush 4 is provided with a groove 6, the groove 6 extends along the sliding direction of the carbon brush 4, the conductive probe 5 is inserted in the groove 6, the The contact portion of the carbon brush 4 described above is the groove wall at the end of the groove 6 . The side of the end of the conductive probe 5 facing away from the moving direction of the carbon brush 4 is the probe arc surface 8. When the carbon brush 4 is in the second working state, the probe arc surface 8 and the carbon brush 4 are in the second working state. The contact parts of the carbon brushes 4 are in contact. The groove wall at the end of the groove 6 is a groove side arc surface 9 . Referring to FIG. 5 , there is a distance between the rear end of the groove 6 and the rear end of the carbon brush 4 , that is, there is still a distance between the end of the groove 6 and the rear end of the carbon brush 4 . When the end side of the carbon ...

Embodiment 2

[0018] Embodiment 2 Referring to FIG. 8 , the contact part of the carbon brush 4 is a metal conductive bump 10 whose root is embedded in the carbon brush 4 and whose outer end protrudes from the surface of the carbon brush 4 .

Embodiment 3

[0019] Embodiment 3 Referring to FIG. 9 , the contact portion of the carbon brush 4 is a raised carbon brush bump 12 provided on the surface of the carbon brush.

[0020] The sides of the outer ends of the conductive bump 10 of the second embodiment and the carbon brush bump 12 of the third embodiment facing the moving direction of the carbon brush 4 are also arc-shaped surfaces, which have the same function as the groove-side arc-shaped surface 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com