Method for converting sodium gulonate to gulonic acid in Vit C production

A technology for the conversion of sodium gulonate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems affecting industrial separation efficiency and benefits, large amount of water and chemical reagents, large amount of waste water discharge, etc. , to achieve the effect of comprehensive optimization of process flow, small footprint and saving regeneration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

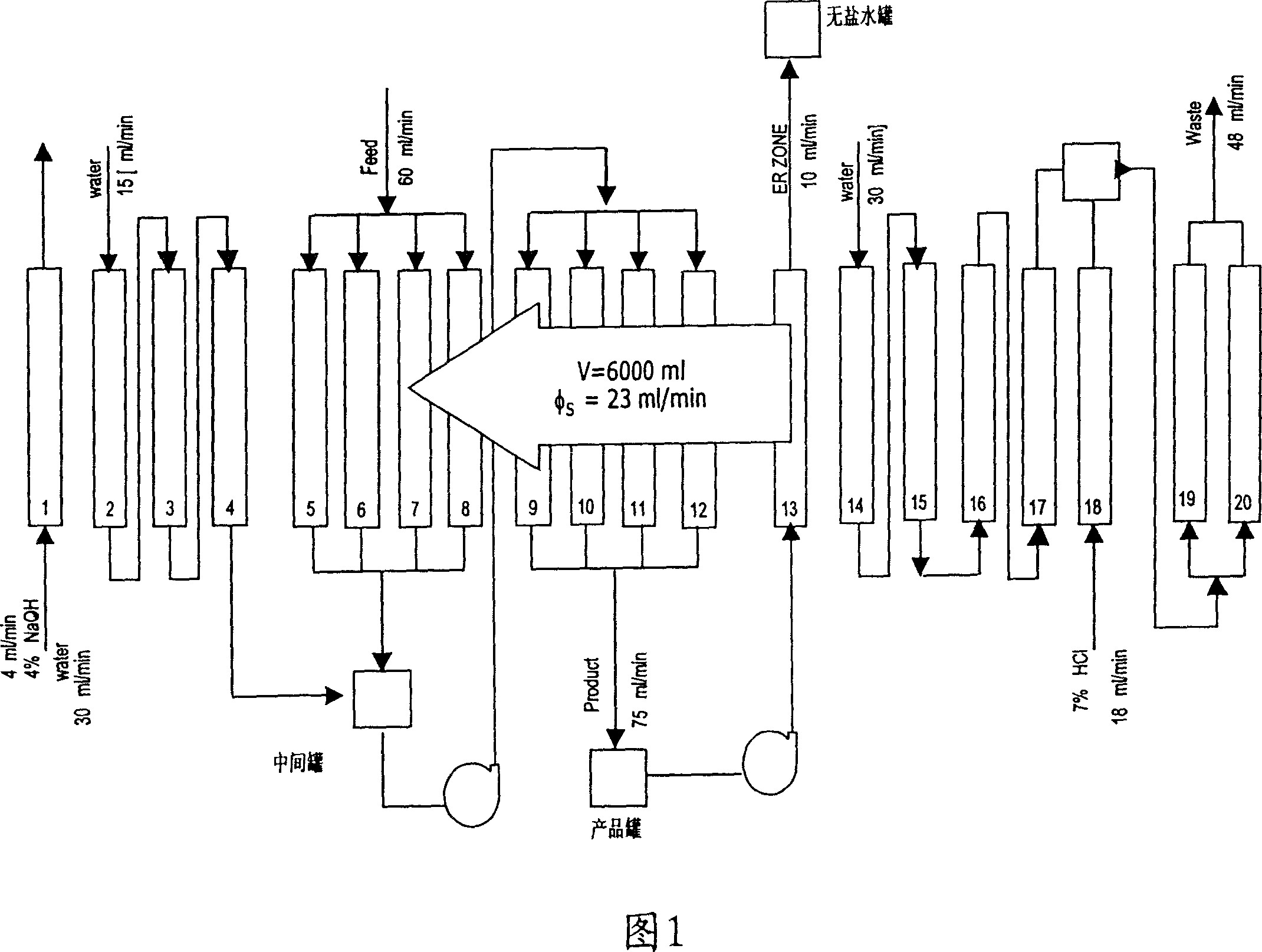

[0026] As shown in Figure 1, it is a process flow diagram of the present invention converting sodium guronate through continuous ion exchange. The present invention adopts the disc conveying type continuous countercurrent adsorption system, and adopts 732 strong acid type cation exchange resin. The continuous ion exchange process flow includes 20 unit systems as an example, and the processing capacity is 3-3.9L / H. According to the sodium gluconate itself The characteristics of the resin, the resin filling volume of each column is 300ml, the rotation speed is 18 degrees, and it is divided into the following subsections:

[0027] In the exchange area (including the 5th to 12th units), the parallel connection of the 5th to 8th units and the parallel connection of the 9th to 12th units are adopted. The feed liquid is in the forward mode; the feed flow rate of the feed liquid is 60ml / min;

[0028] After the exchange, the washing area (including the 2nd to 4th units) adopts the sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com