Device for the transport and wet-chemical or electrolytic treatment of very thin and planar items to be treated

An electrolytic treatment, very thin technology, used in printed circuit liquid handling, electrolytic processes, electrolytic components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

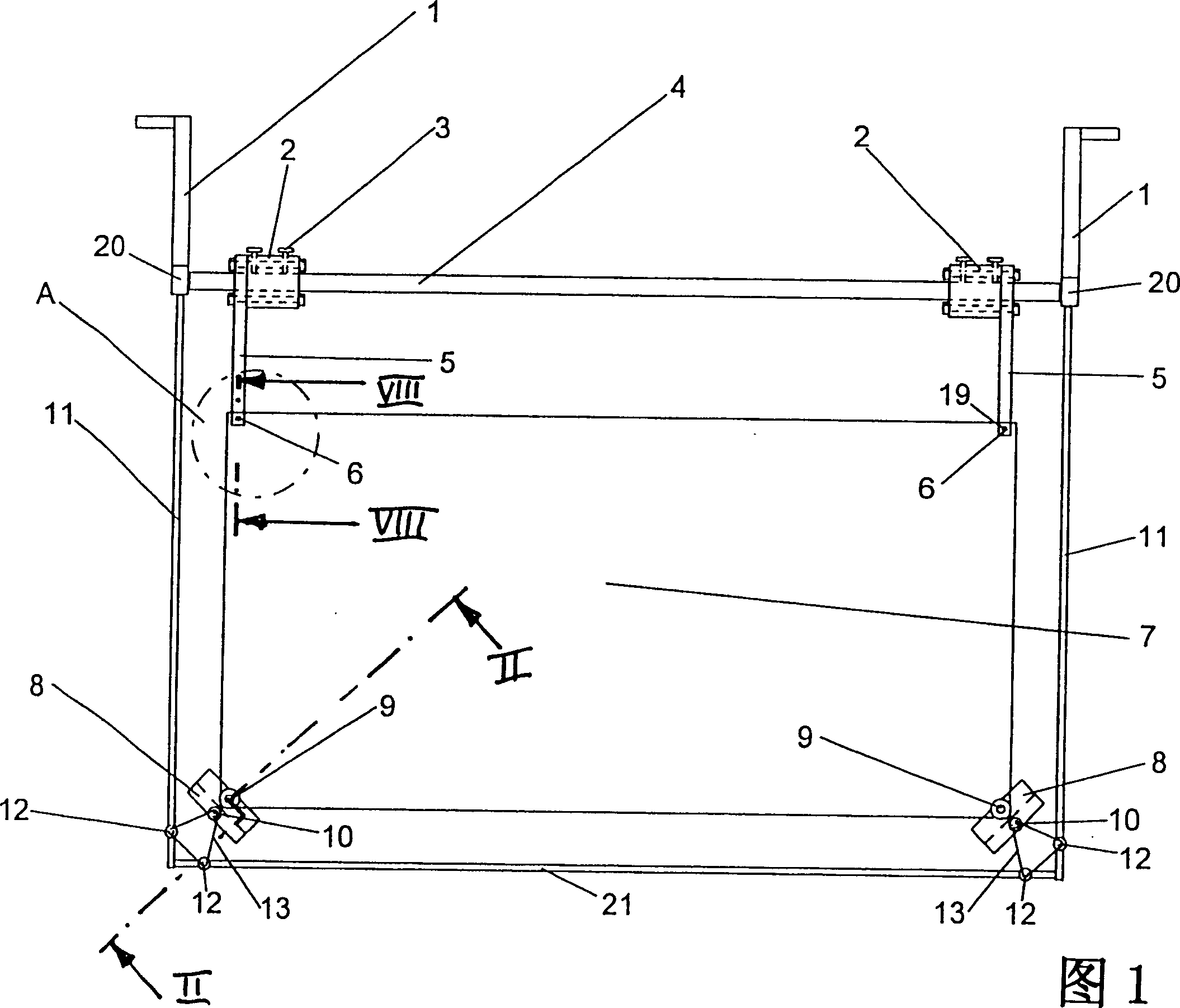

[0017] In order to better understand the illustrated embodiments, specific terms, rather than generic terms, are used to designate structural elements. The same reference numerals are used to designate the same elements or elements having the same function.

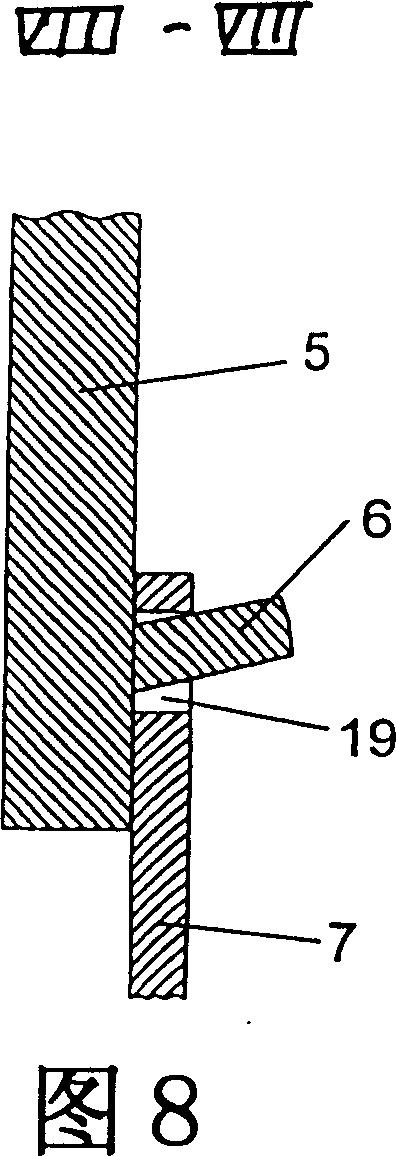

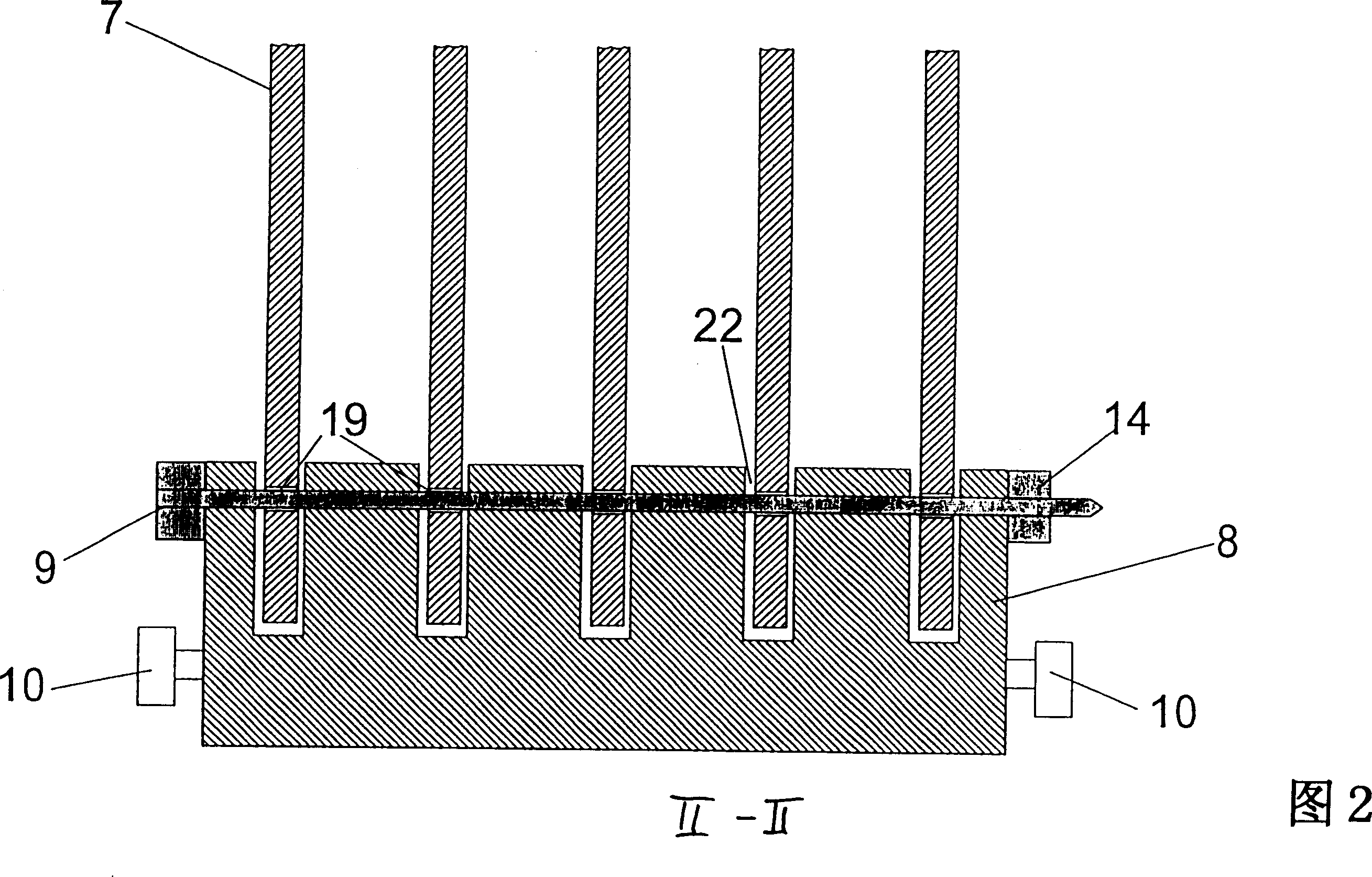

[0018] The detachable fastening 3 on the support block 2 is designated, for example, as a locking screw. However, other securing mechanisms may also be used, such as spring-actuated clamps, toggle levers, cams, etc. The same applies to the suspension elements 10 , 12 designated as eg tension rollers. The element may be a hook, a roller with a flange or a notch, or any other protruding part from a corresponding one of the support elements in which the tension element 13 may be suspended, And this element prevents the workpiece from slipping. As mentioned above, the tension element 13 may be a tension band made of elastic plastic material, or a rubber O-ring, an annular tension spring, a tension spring with holes on eith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com