Ignitor

A technology for an appliance and an intermediate housing, which is applied in the directions of combustion ignition, igniter with fuel, combustion method, etc., can solve the problems of complicated assembly, difficult assembly, and difficult ignition, etc. The effect of a reliable lock state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

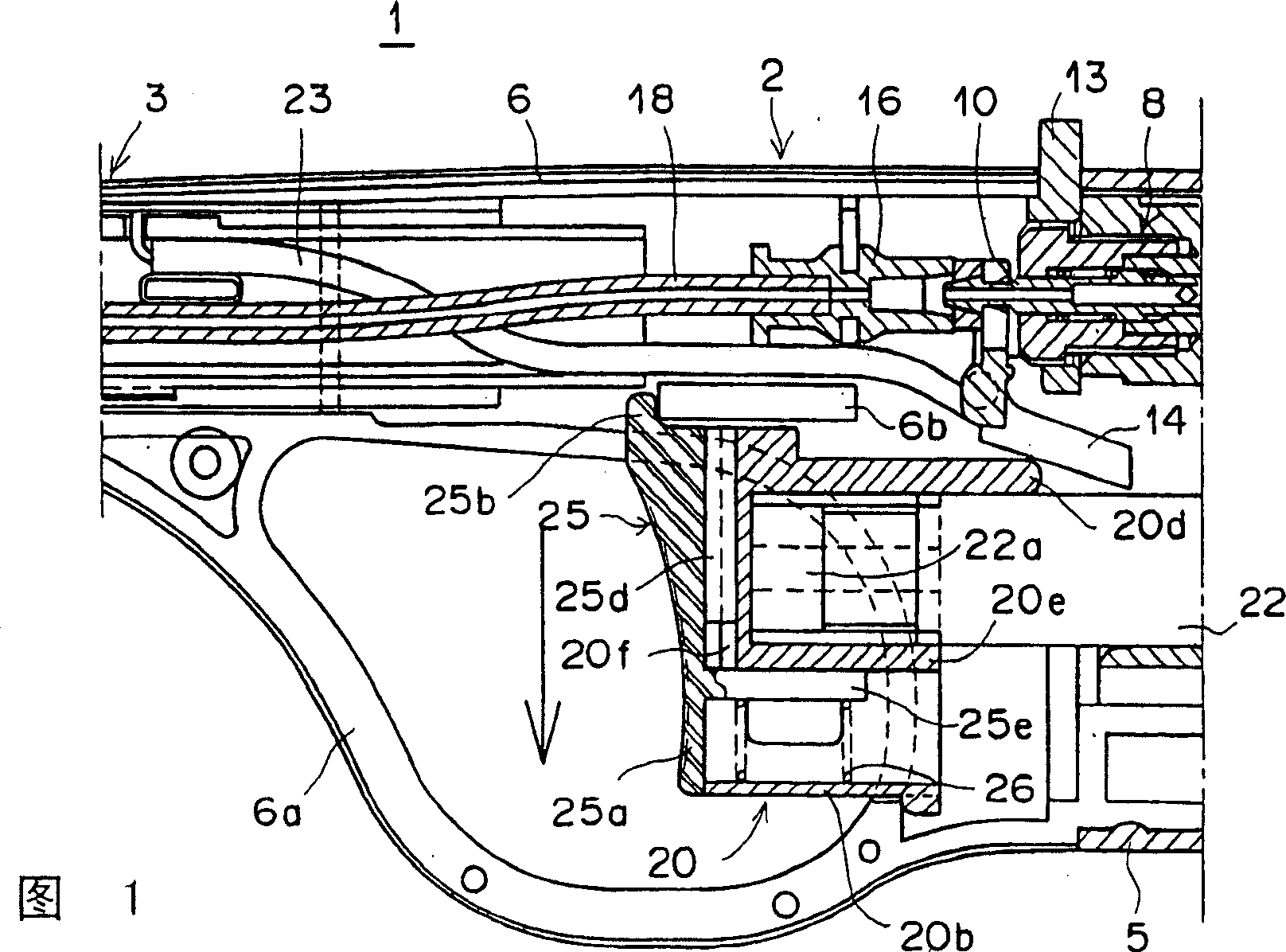

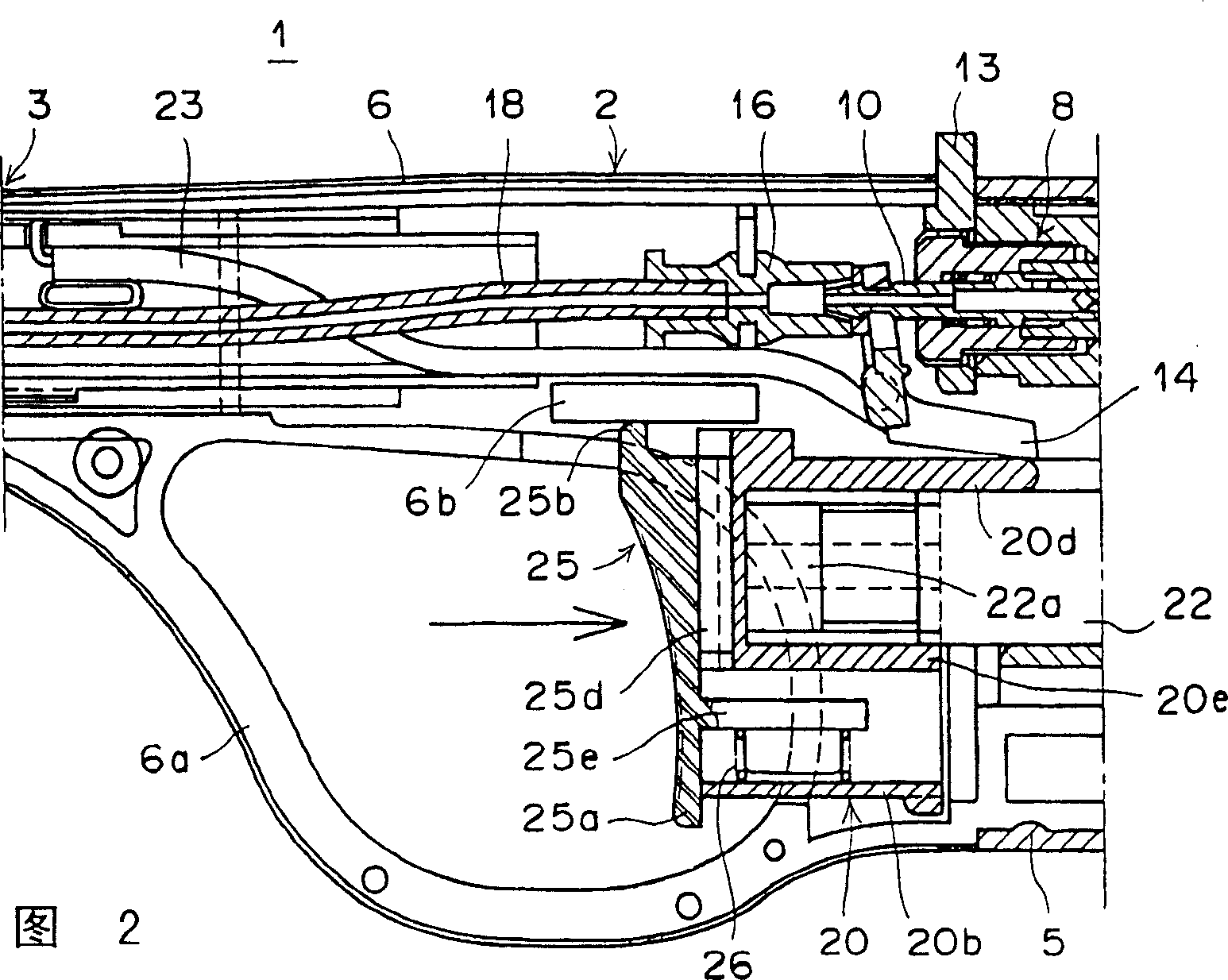

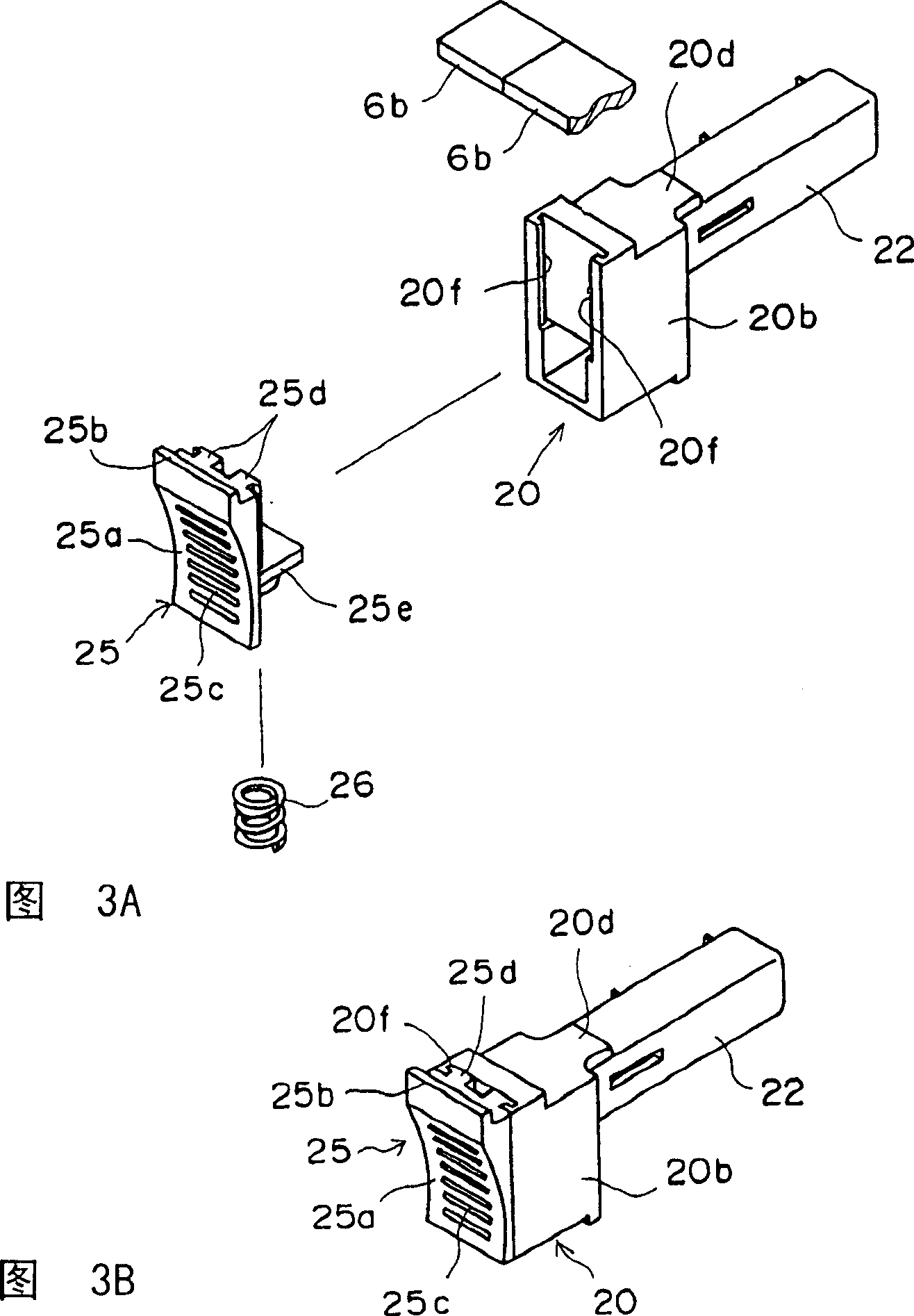

[0035] Fig. 1~Fig. 3B shows the igniter constituted by the ignition rod of this embodiment, Fig. 1 is a sectional view of main parts, Fig. 2 is a sectional view of an operating state, and Fig. 3A and Fig. 3B are perspective views of a locking mechanism.

[0036]The igniter (ignition rod) 1 of the present embodiment is composed of a device body 2 and an extended tip portion 3 extending in a rod shape (the tip portion is omitted in the figure). The appliance body 2 is formed of a synthetic resin-molded gas storage tank portion 5 and an intermediate case 6. The intermediate case 6 is divided longitudinally at approximately the center in front of the gas storage tank portion 5. FIGS. 1 and 2 show the intermediate case. 6 for one.

[0037] A gas storage chamber (not shown in the figure) is provided on the base end side (right side of the figure) of the appliance body 2 for storing high-pressure gas such as butane gas in the gas storage tank portion 5. A valve mechanism 8 is provid...

no. 2 Embodiment approach

[0053] 4 is a sectional view of main parts of an ignition device provided with a locking mechanism according to another embodiment; FIG. 5 is a sectional view showing an operating state; and FIGS. 6A and 6B are perspective views of the locking mechanism.

[0054] The lock mechanism in the igniter 11 of this embodiment is different from that of the first embodiment, except that the lock member 27 and the form of the engaging portion 6c are different, the operating member 20, the piezoelectric assembly 22 (ignition device), and the biasing member 26 are all the same. The configuration is the same, so the same parts are given the same symbols and their descriptions are omitted.

[0055] In this embodiment, the locking position and the unlocking position of the locking member 27 are configured opposite to those of the locking member 25 of the first embodiment described above.

[0056] The locking member 27 also serves as an operating portion of the operating member 20 , is slidabl...

no. 3 Embodiment approach

[0064] Fig. 7 is a sectional view of main parts of an ignition device provided with a lock mechanism according to still another embodiment of the present invention, and Fig. 8 is a sectional view showing a state in which the lock is released.

[0065] The igniter of this embodiment (another embodiment of the ignition rod) 12 is composed of an appliance body 4 different in shape from the above-mentioned embodiment and a rod-shaped extension front portion 7 extending from the center of the appliance body 4 (the front end portion is omitted in the figure). )constitute. The appliance body 4 is formed of a synthetic resin molded gas storage tank portion 9 and an intermediate case 60 split longitudinally at the front substantially in the center. FIGS. 7 and 8 show one of the intermediate cases 60 . The intermediate case 60 is formed in a circular shape with a finger insertion window 60a opened in the center.

[0066] The gas storage tank portion 9 on the base end side (the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com