Tangential discharge disk refiner

a technology of tangential discharge and refiner, which is applied in the field of refiners, can solve the problems of poor bond formation and limited paper made of raw fibers, and achieve the effect of improving the overall performance and facilitating the hydrodynamic balance of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

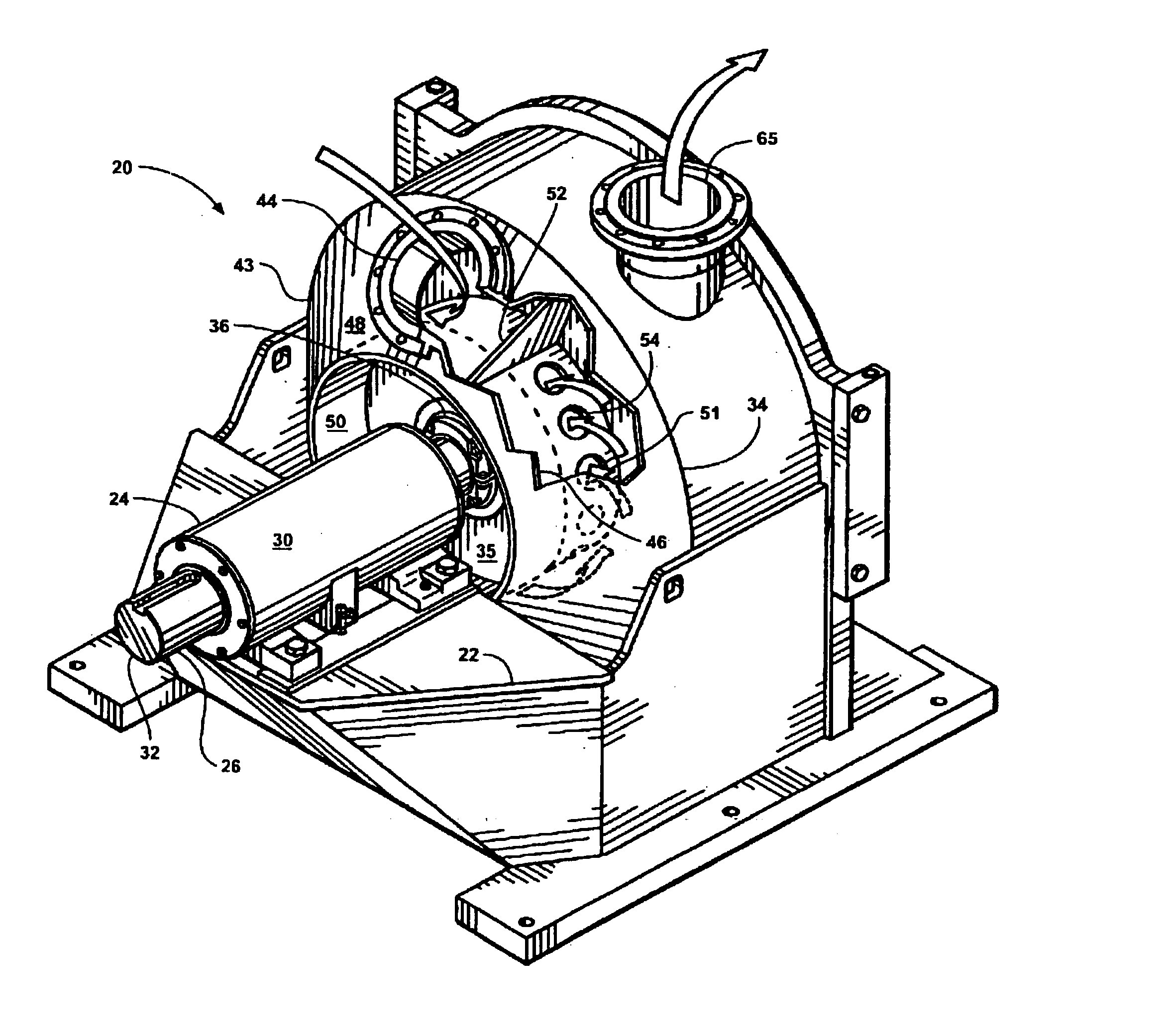

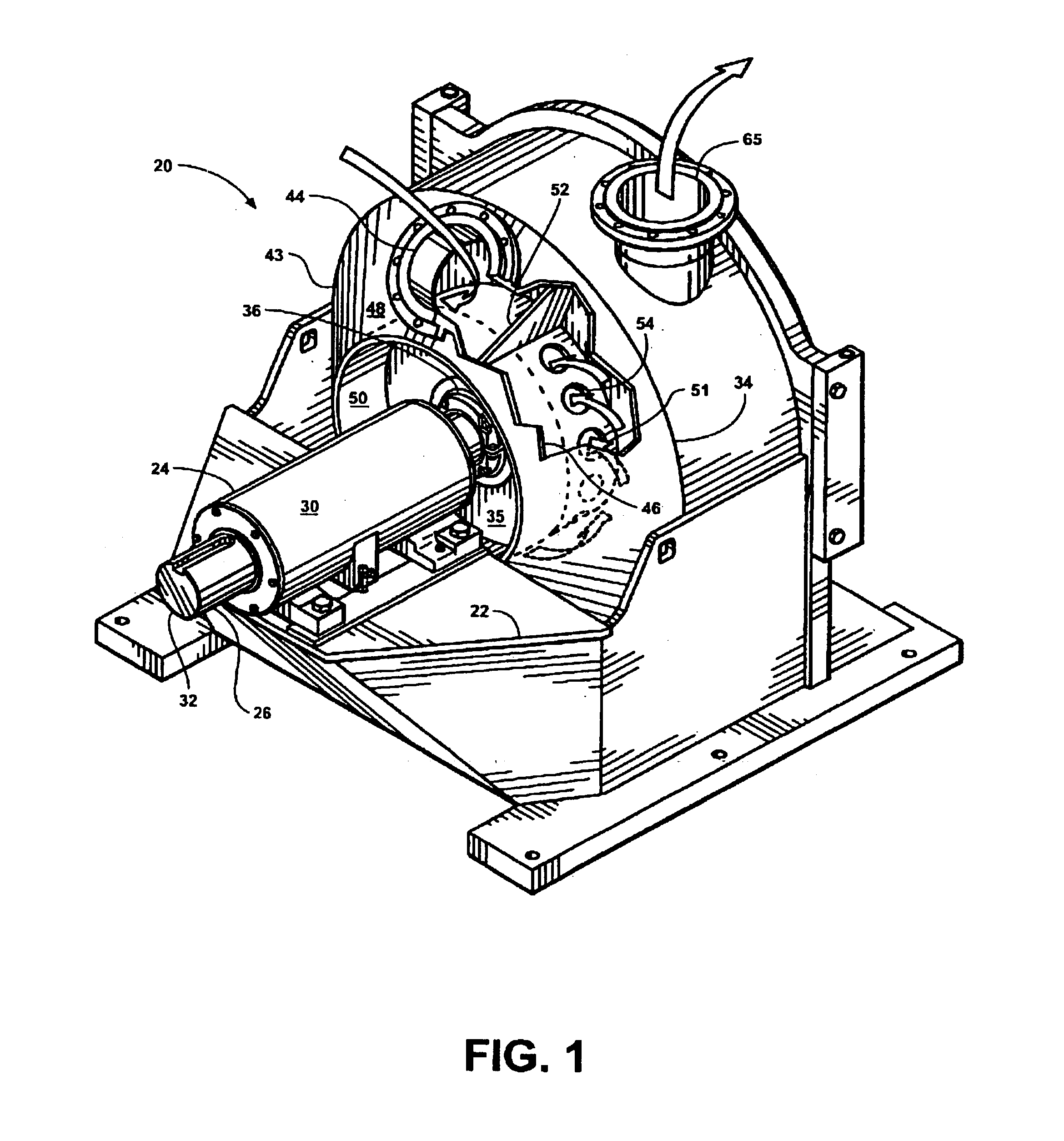

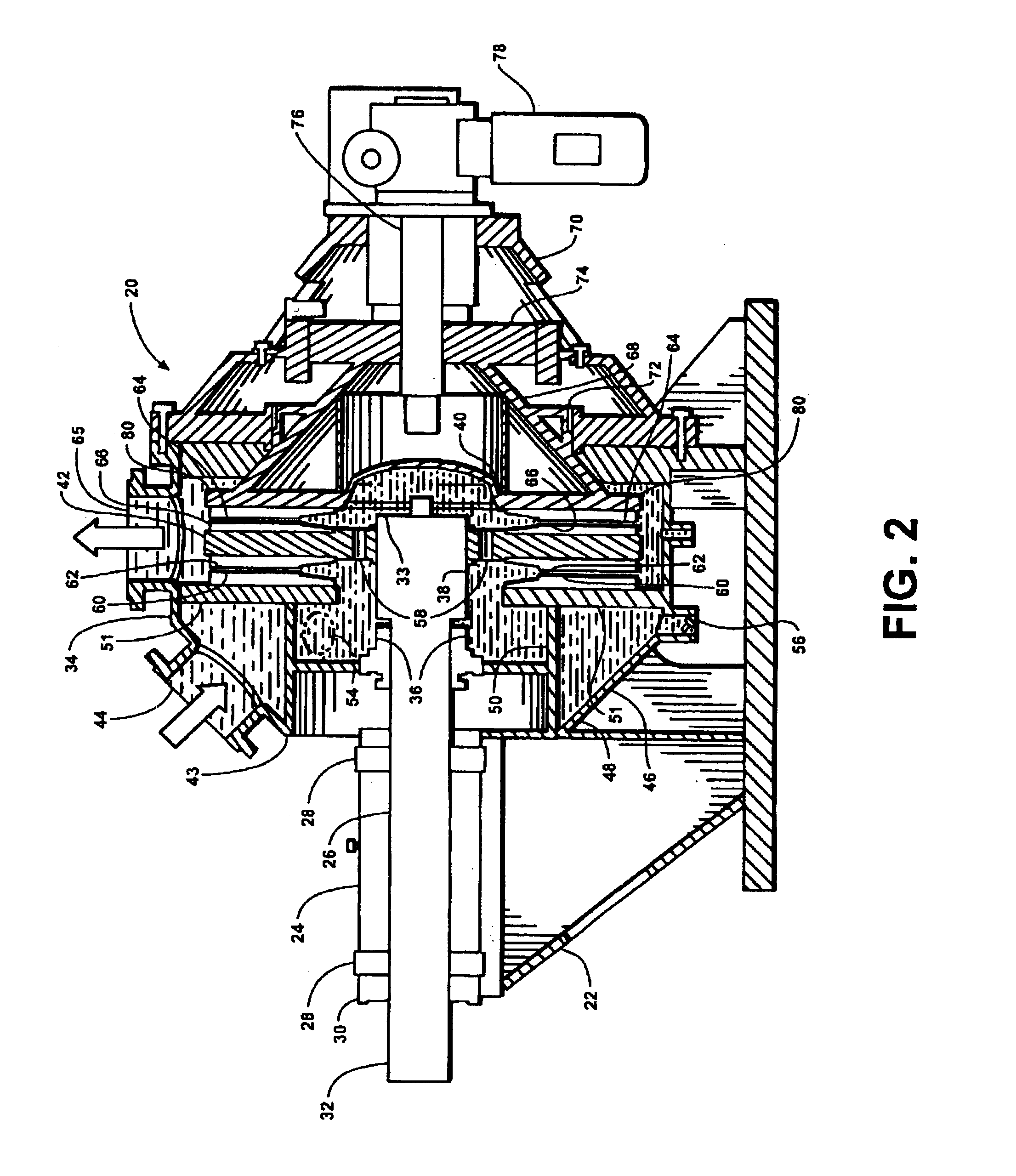

[0022]Referring more particularly to FIGS. 1-3 wherein like numbers refer to similar parts, a double disk refiner 20 is shown in FIGS. 1-3. The refiner 20 has a machine frame 22 on which is mounted a rotating assembly 24 having a shaft 26 mounted by bearings 28 to a shaft case 30. The shaft 26 is connected at a first end 32 to a drive motor (not shown). A second end 33 of the shaft 26 passes into a refiner housing 34 through a circular bulkhead 35 at a removable packing box 36. As shown in FIG. 2, the second shaft end 33 is machined to form a spline 38 to which the hub 40 of a rotor 42 is mounted.

[0023]The drive side 43 of the refiner housing 34 has a stock inlet 44 which supplies stock to a shroud 46 defining a triangular cross-section passageway between an outer conical shell 48, an inner cylindrical structure 50, and a drive side stationery plate support structure 51. The inner cylindrical structure 50 surrounds the bulkhead 35. The shroud 46 causes the stock to rotate producing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com