Pinnacle truss

a pinnacle and truss technology, applied in the direction of girders, joists, trusses, etc., can solve the problems of insufficient overall structure of the frame, stress and strain production in the gap, etc., and achieve the effect of eliminating potential stress and strain and strengthening the overall structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

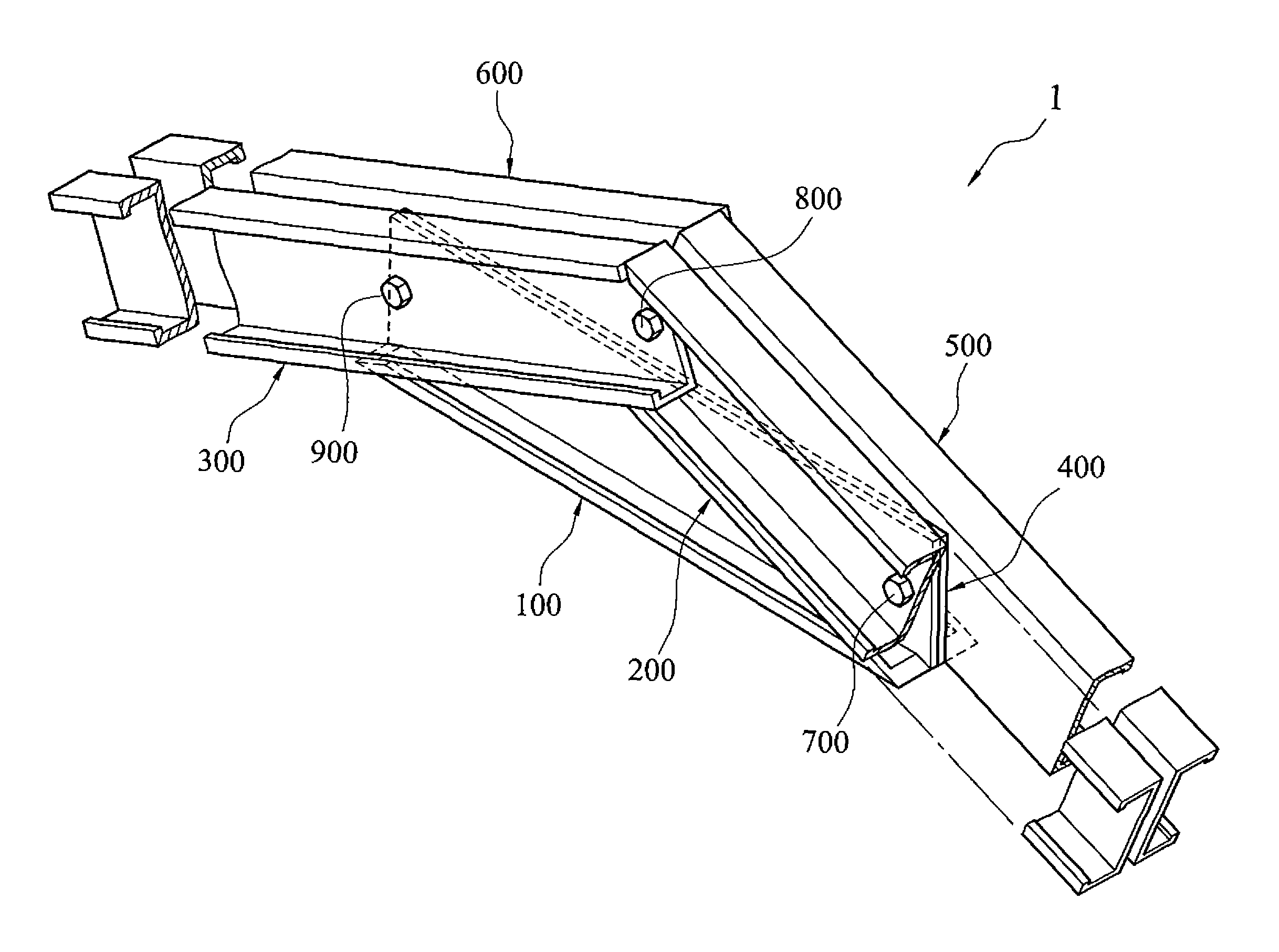

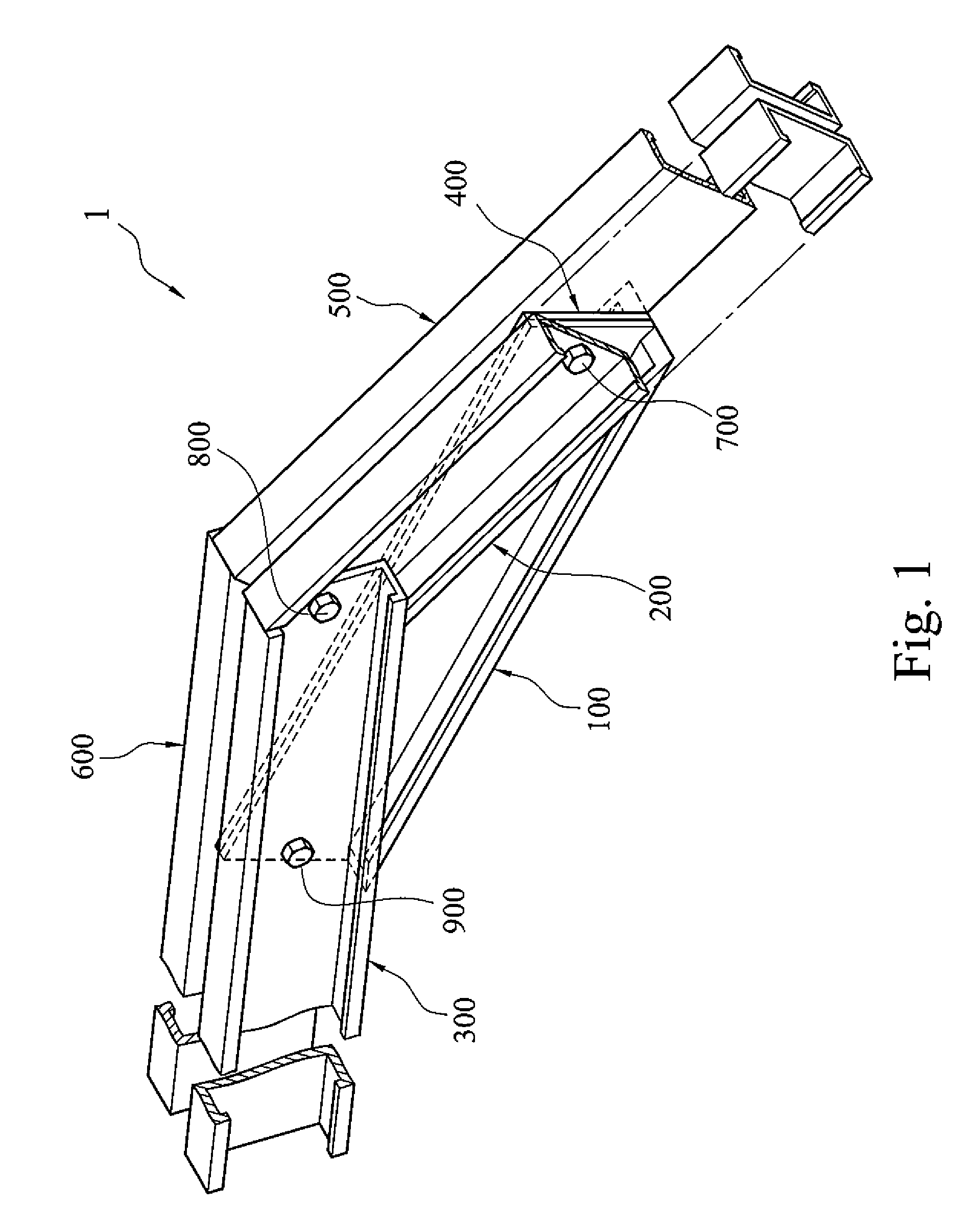

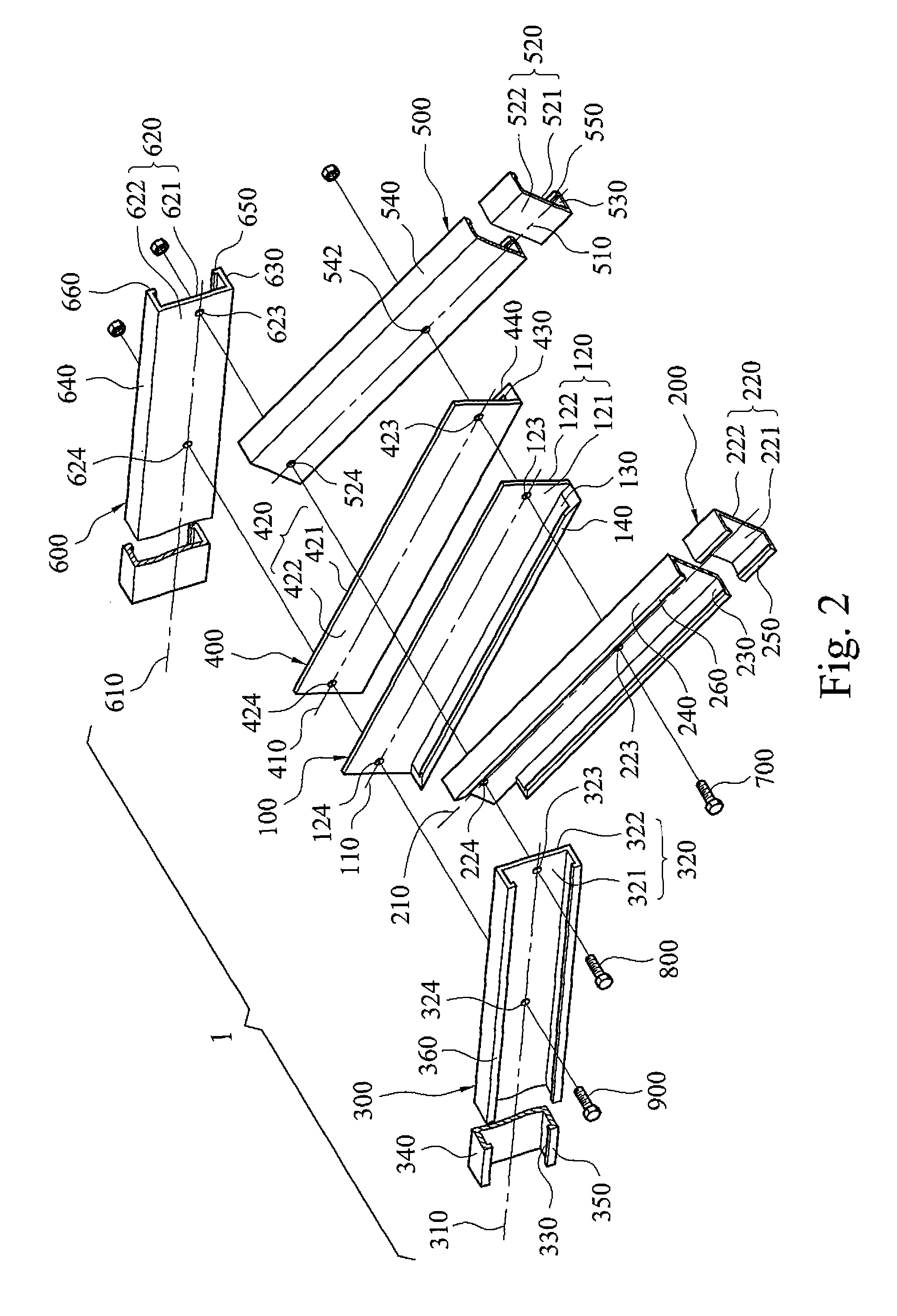

[0015]Referring now to the attached drawings for the description of this invention, various structures, systems and devices are schematically depicted in the drawings only for the purpose of illustration without obscuring this invention by details known by persons skilled in the art. However, it still contains the attached drawings to describe and illustrate the embodiments of this invention. Words and phrases used herein should be understood and interpreted as those with consistent meaning by persons skilled in the art. Terms and phrases consistently used here are not intended to imply specific definition, namely different from general and conventional definition known by persons skilled in the art. Terms or phrases are intended to expand specific definition, for example, definition outsides the understanding by persons skilled in the art. This specific definition will be clearly expressed in this specification in such a way that specific definition is directly and definitely provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com