Plasma display apparatus and driving method thereof

a technology of display apparatus and plasma, which is applied in the direction of electric digital data processing, instruments, computing, etc., can solve the problems of excessive displacement current flowing through the data driver ic, electrical damage, and lowering the contrast value of dark room, so as to reduce noise generation and prevent the generation of erroneous discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0105]FIGS. 9a and 9b are views illustrating a driving method of a plasma display apparatus according to the present invention.

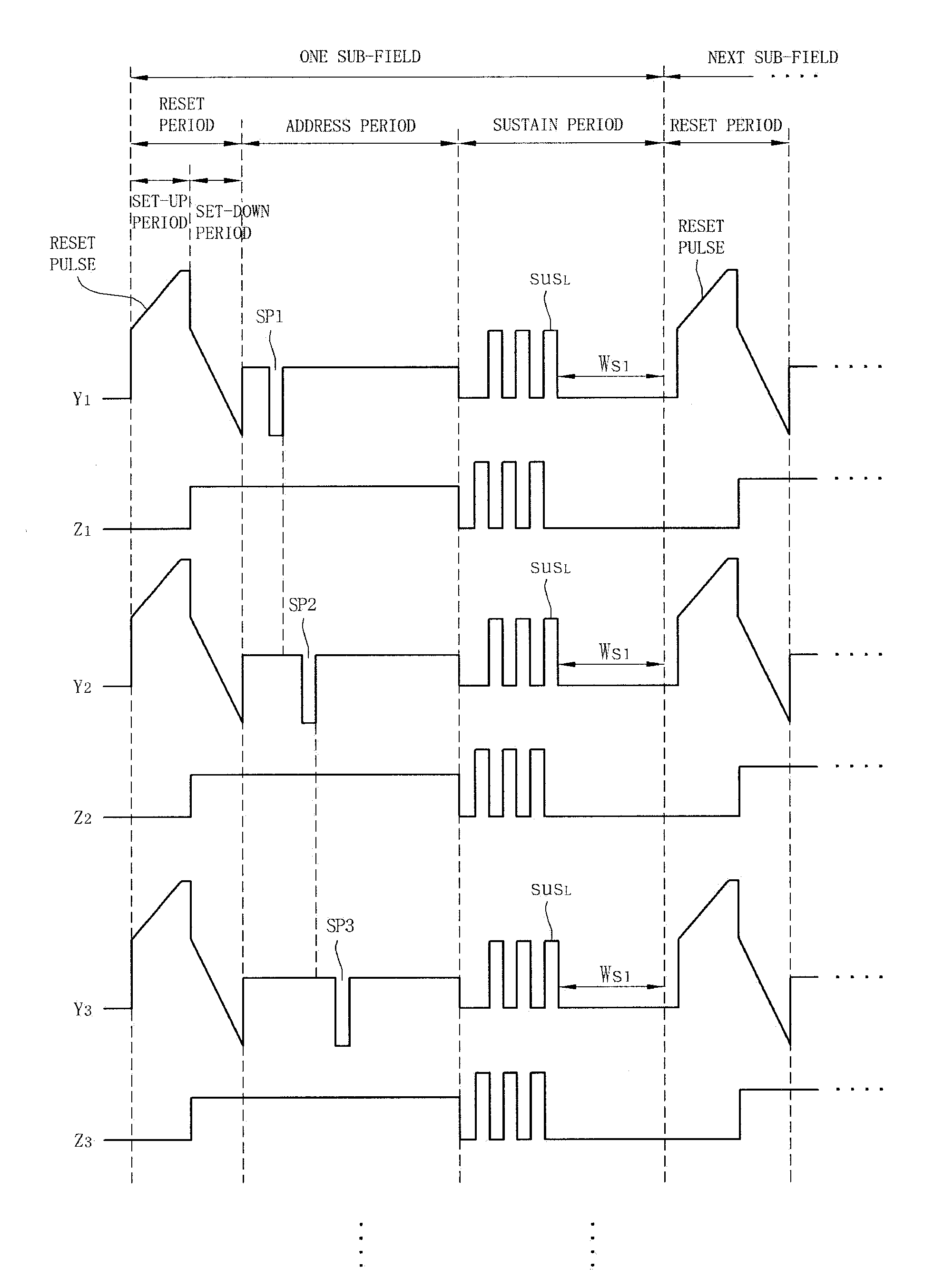

[0106]Referring first to FIG. 9a, in the method of driving the plasma display apparatus according to a first embodiment of the present invention, the plasma display apparatus is driven with a driving waveform being divided into a reset period, an address period and a sustain period in one frame, as described above.

[0107]In a set-up period of the reset period, a ramp-up waveform (Ramp-up) is applied to scan electrodes Y. The ramp-up waveform generates a weak dark discharge within discharge cells of the entire screen. The ramp-up discharge also causes positive wall charges to be accumulated on data electrodes X and sustain electrodes Z, and negative wall charges to be accumulated on the scan electrodes Y.

[0108]In a set-down period of the reset period, after the ramp-up waveform is applied to the scan electrodes Y, a ramp-down waveform (Ramp-down), which falls ...

second embodiment

[0293]FIG. 27 is a view illustrating a method of controlling a difference between an application time of a last sustain pulse and an application time of a reset pulse applied in a reset period of a next sub-field according to the present invention.

[0294]Referring to FIG. 27, (a) of FIG. 27 shows the relation between a last sustain pulse (SUSL) applied in a sustain period of any one of sub-fields and a reset pulse applied in a reset period of a next sub-field. FIG. 27 shows a case where the last sustain pulse (SUSL) is applied to the scan electrodes Y. It is, however, to be noted that the last sustain pulse (SUSL) can be applied to the sustain electrodes Z.

[0295](b) of FIG. 27 shows a difference (Ws2) between application times in the remaining sustain pulses other than the last sustain pulse (SUSL).

[0296]Referring to (a), a time lag of Ws1 is placed between then application time of the last sustain pulse (SUSL) and the application time of a reset pulse applied in a reset period of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com