Electrical distribution panel including first non-critical load bus and second critical load bus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

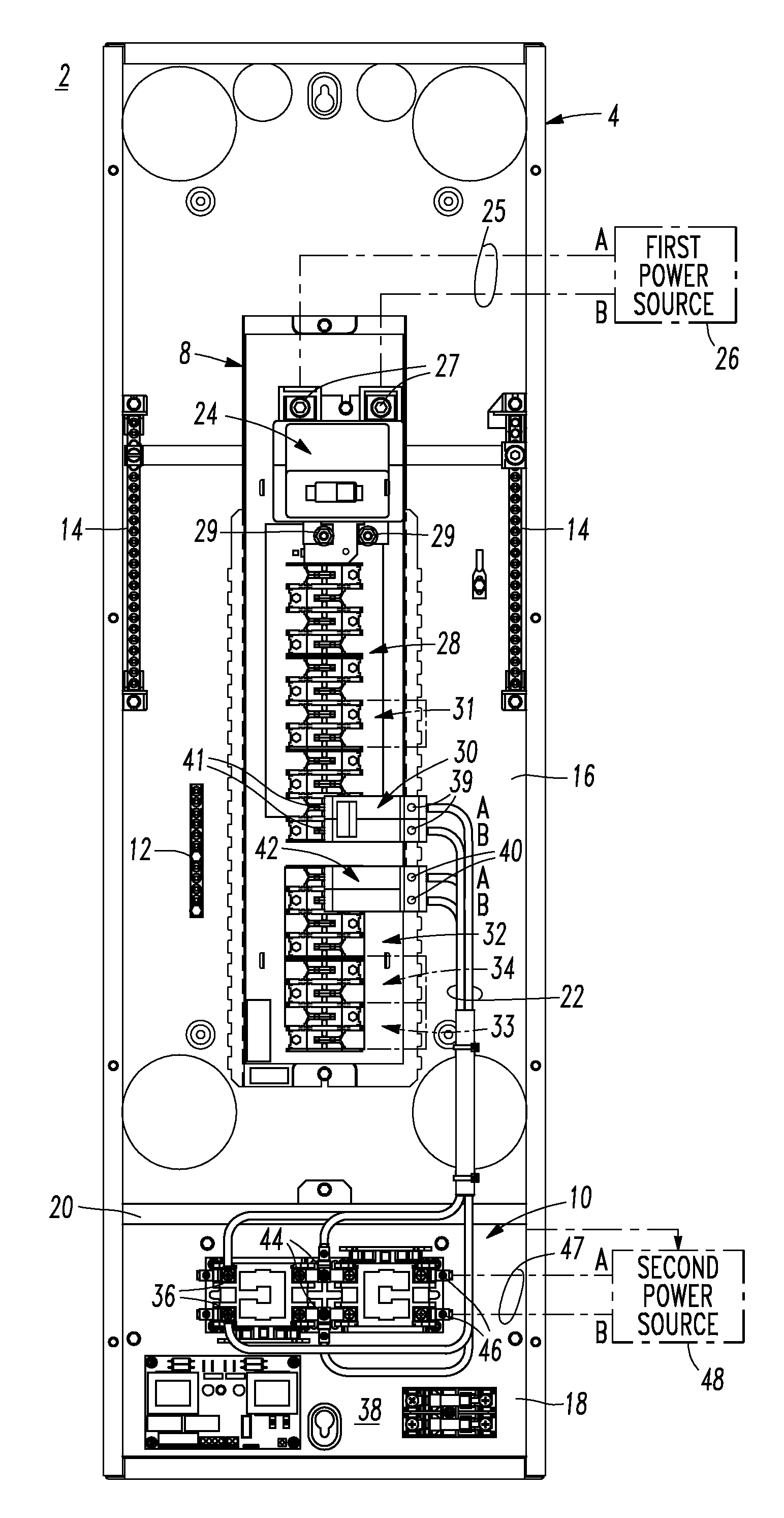

[0047]Although an example 50A version of the critical circuits of the ATS load center 202 is disclosed, a wide range of other current ratings can be provided. The branch mounted circuit breaker 30 can be a plug-on, two pole, 50 A, 240 V circuit breaker. This circuit breaker 30, when closed, supplies the second bus 32 of the load center 202 with first power from the first power source 26 (as shown in FIG. 1) under normal operation. After the ATS kit 106 (FIG. 4) is installed, the circuit breaker 30, when closed, energizes the ATS 38 until the first power is interrupted. After the first power is interrupted, the electronics (not shown) of the ATS 38 recognize the interruption and automatically start the generator 48 (as shown in FIG. 1).

example 2

[0048]The sub-feed lug block 42 becomes the point of electrical connection for power being supplied to the second bus 32 of the load center 202. The example sub-feed lug block 42 is two pole, 125 A. The sub-feed lug block 42 provides power to the second bus 32 of the load center 202, whether it is initially supplied from the branch mounted circuit breaker 30 (FIG. 3) or from the ATS 38 (FIGS. 1 and 5) after the ATS kit 106 (FIG. 4) has been installed.

example 3

[0049]The example ATS 38 has two legs, A and B. Leg A to neutral N provides 120 V, leg B to neutral N provides 120 V, and leg A to opposite leg B provides 240 V, although the invention is applicable to an ATS having any number of legs and / or any suitable number of voltages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com