Anti-cavitation valve assembly

a technology of anti-cavitation valves and assembly parts, which is applied in the direction of valve member-seat contacts, mechanical equipment, transportation and packaging, etc., can solve the problems of forming literally thousands of minute bubbles, excessive noise and vibration of valves, and hearing loss of plant personnel, so as to reduce the pressure through the valve, eliminate cavitation and its attendant disadvantages, and minimize damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

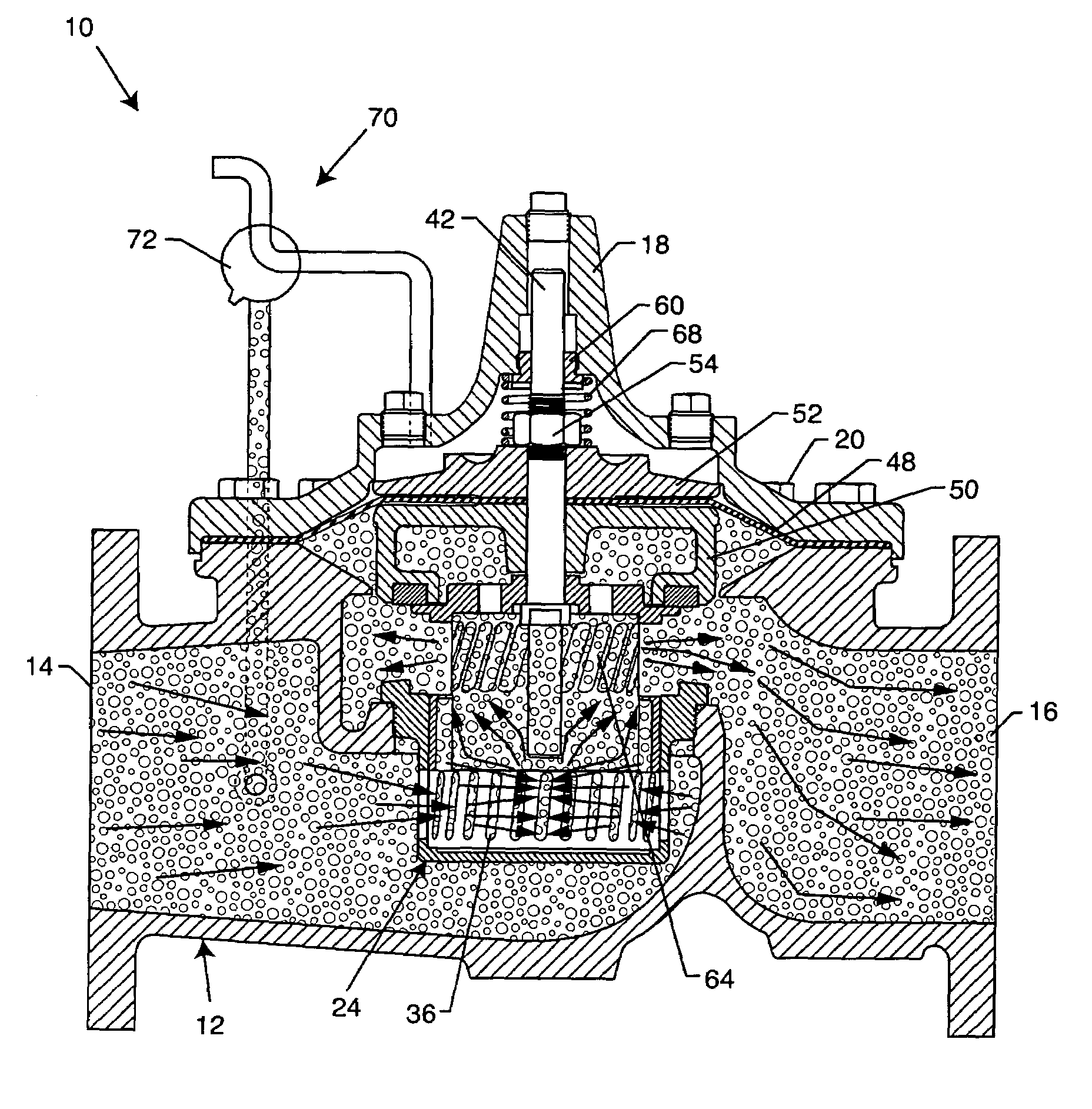

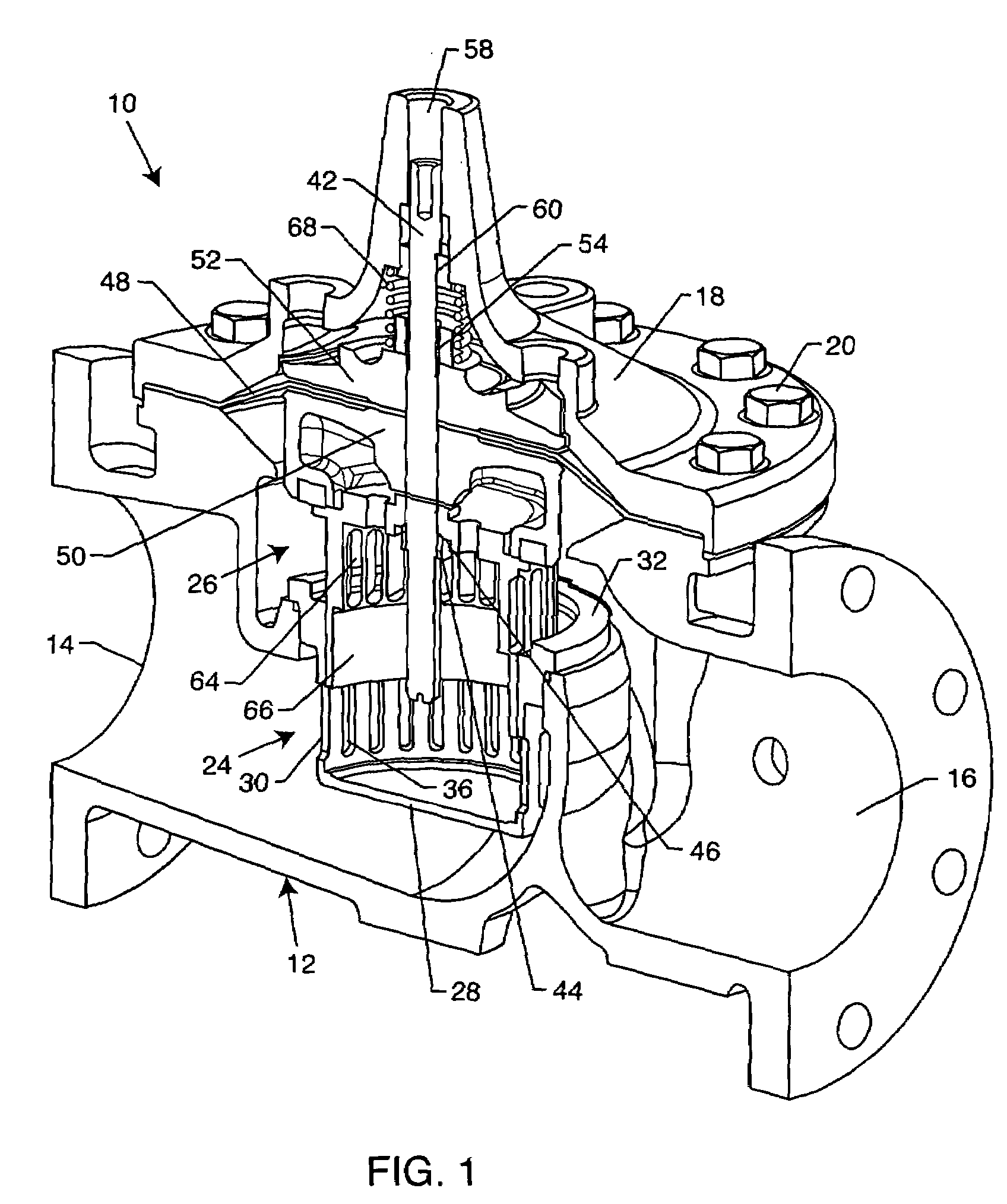

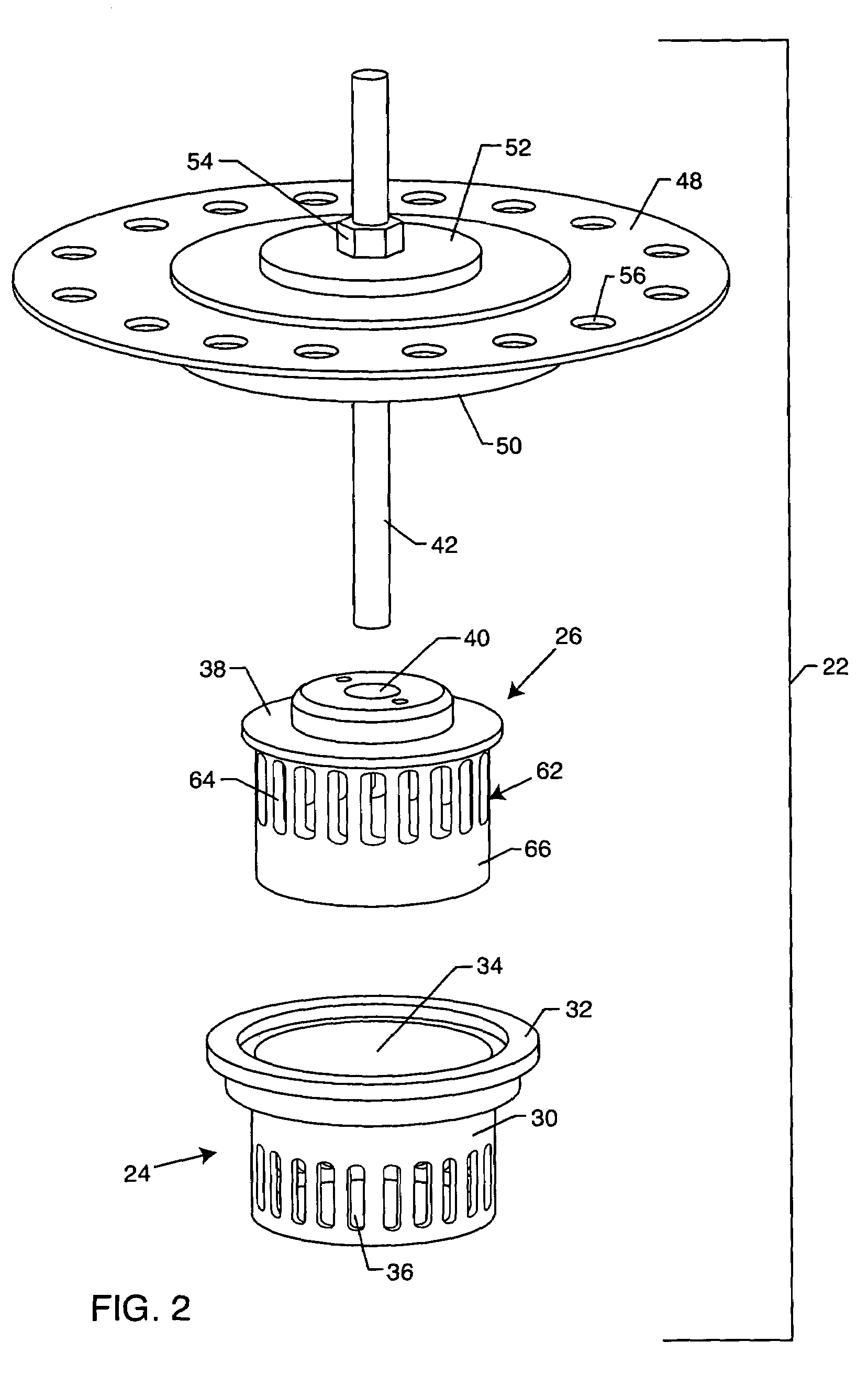

[0022]As shown in the accompanying drawings for purposes of illustration, the present invention resides in a valve assembly, generally referred to by the reference number 10. The assembly 10 of the present invention, as will be more fully described herein, is designed and configured to reduce fluid pressure through the valve assembly 10, while substantially eliminating cavitation. The valve assembly 10 of the present invention also directs the fluid in such a manner that erosion damage is minimized.

[0023]With reference now to FIG. 1, the valve assembly 10 includes a body or housing 12 defining a fluid inlet 14 and a fluid outlet 16. As illustrated, this fluid inlet 14 and outlet 16 are at generally opposite sides of the housing 12. A cover 18 is disposed on the housing 12 and attached or fixed into place using bolts 20 or the like. The housing 12 and cover 18 define the major pressure boundaries of the assembly 10, and collectively form an inner-fluid chamber between the inlet 14 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com