Over-current protection apparatus

a protection apparatus and overcurrent technology, applied in the direction of resistors emergency protection circuit arrangements for limiting excess voltage/current, etc., can solve the problems of wasting system space, generating large transient current, and too many discrete single devices, so as to increase the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

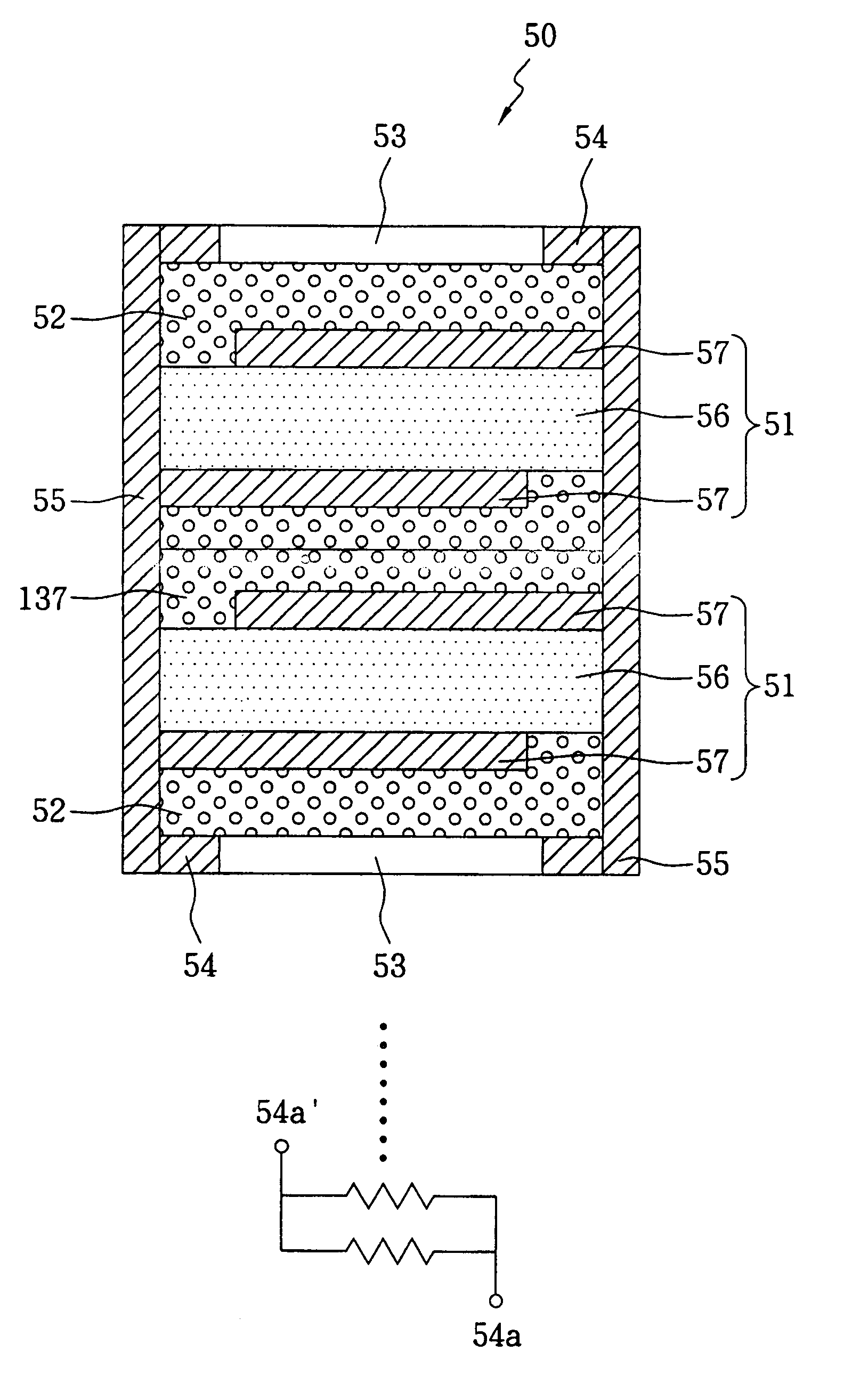

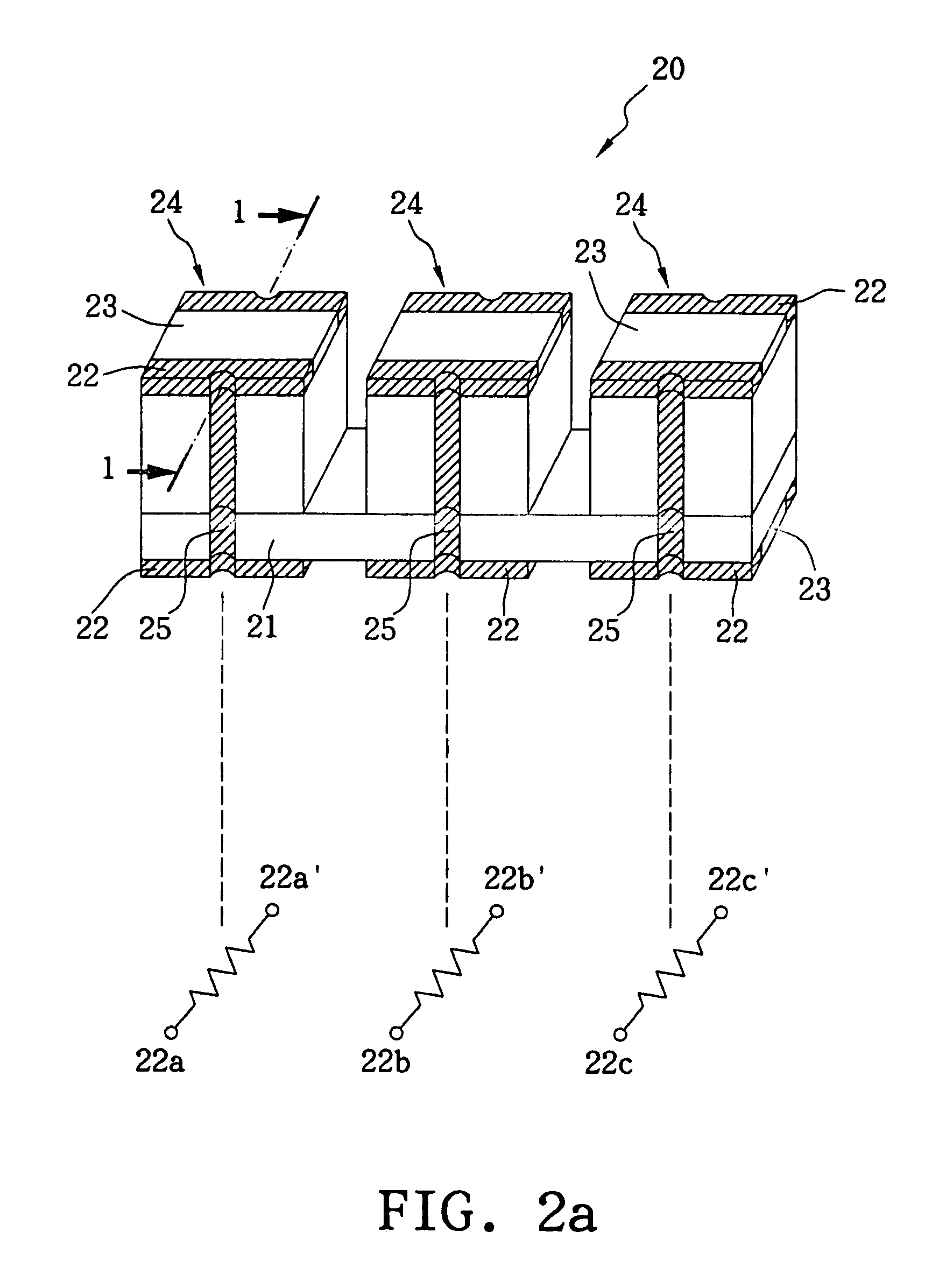

[0020]FIG. 2a illustrates an over-current protection apparatus 20 and the schematic diagram thereof. The over-current protection apparatus 20 comprises a bonding sheet 21 and a plurality of over-current protection devices 24 which are electrically independent, (three over-current protection devices 24 are employed as an example herein,) where the plurality of over-current protection devices 24 are connected in series near the bottom thereof by the bonding sheet 21. Each over-current protection device 24 has upper and lower outer electrode layers 22 serving as end electrodes and solder-mask layers 23, where a semi-cylindrical conductive hole 25 connects the upper and lower outer electrode layers 22. A schematic diagram of the over-current protection apparatus 20 is illustrated in FIG. 2a also, wherein each resistance corresponds to each over-current protection device, individually, and the end electrodes of the resistances are denoted by 22a, 22a′, 22b, 22b′, 22c and 22c′.

[0021]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com