Electrostatic levitation furnance

a technology of electric levitation furnace and electric levitation chamber, which is applied in the direction of furnaces, lighting and heating apparatus, electric/magnetic/electromagnetic heating, etc., can solve the problems of improper use, difficult access to sample samples, and difficulty in increasing the number of access and distribution apparatuses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

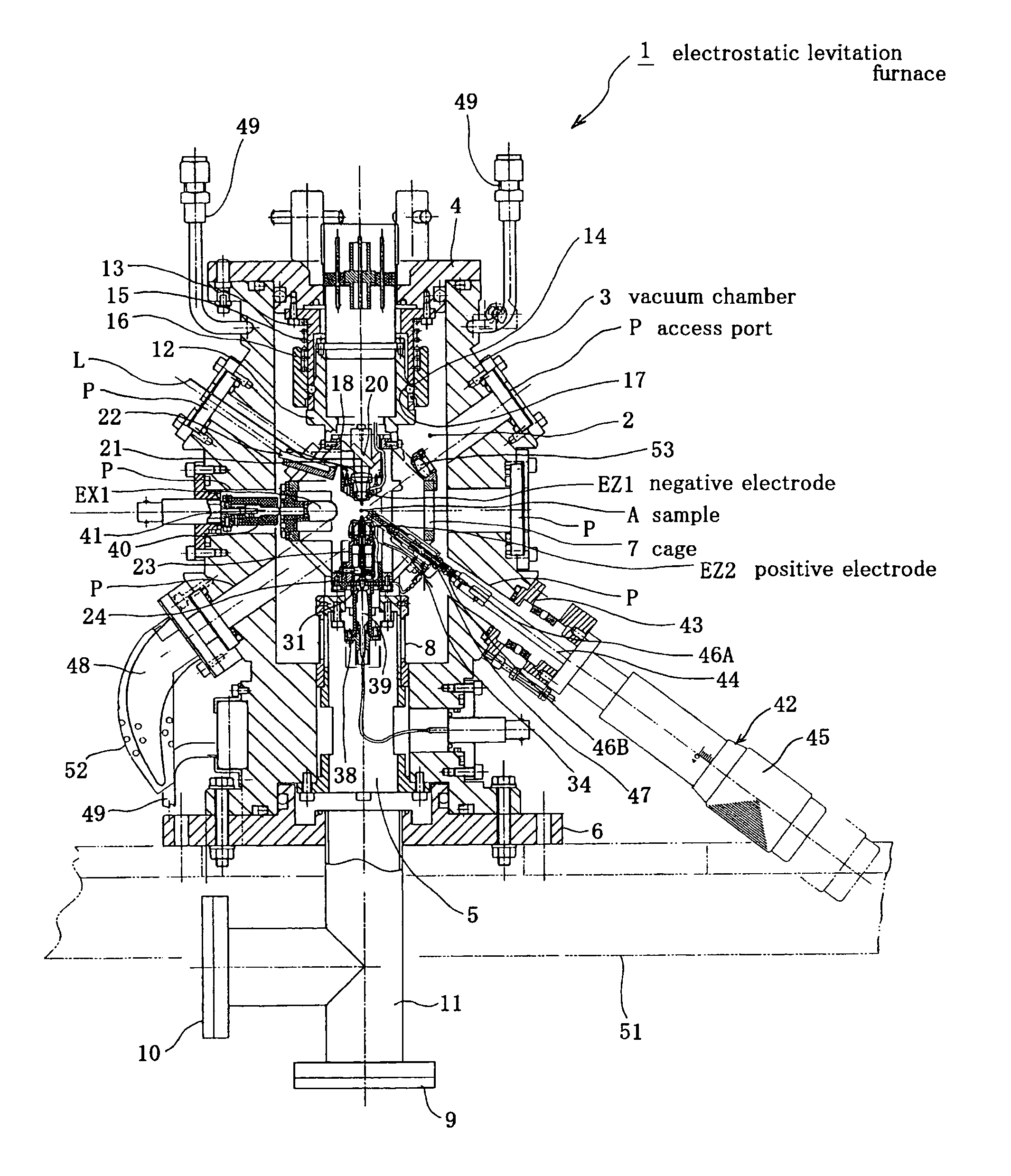

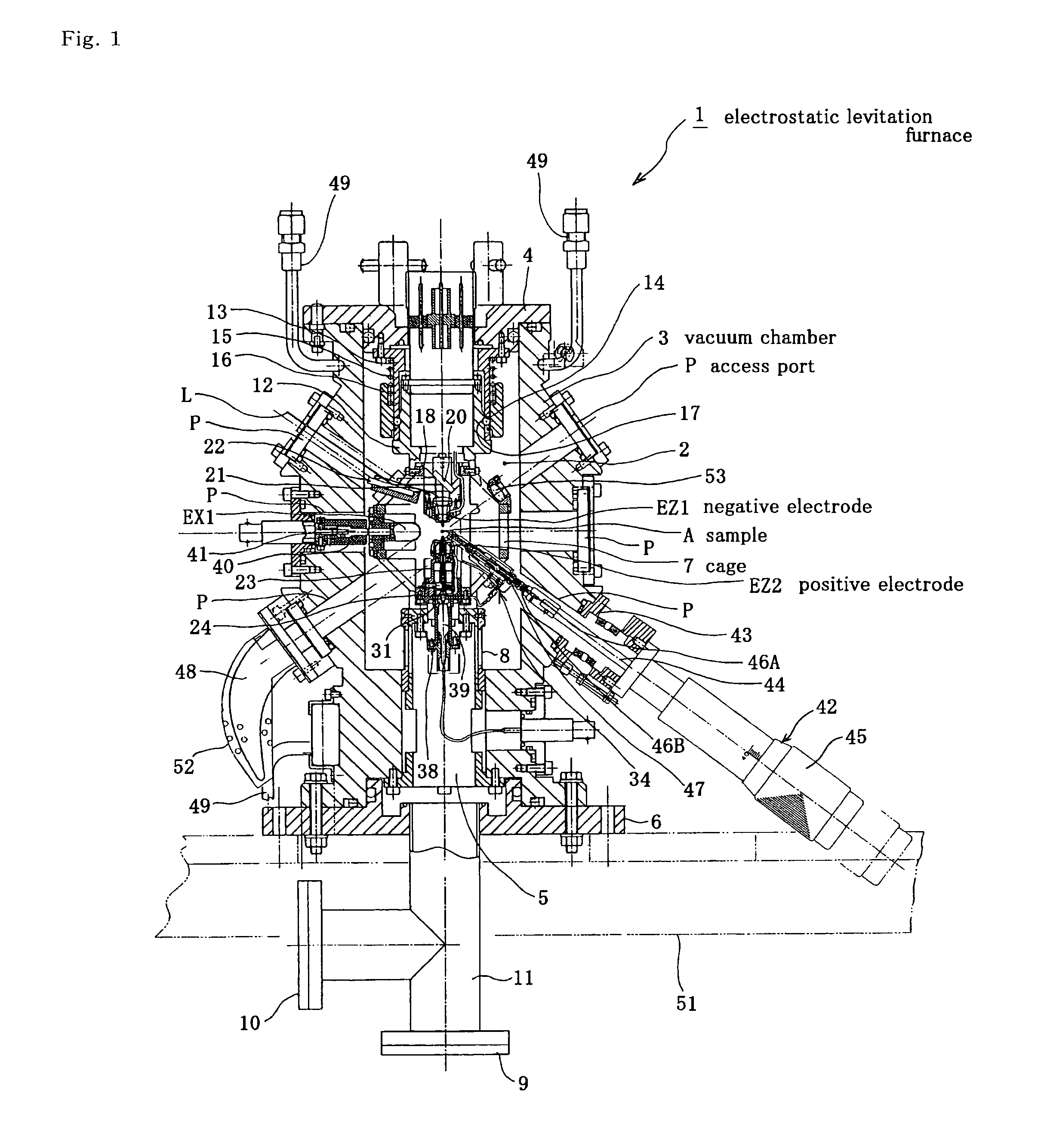

[0048]An example of the electrostatic levitation furnace according to this invention will be described below on basis of the drawings. The electrostatic levitation furnace according to this invention is of course not limited only to the example as described blow in the details of construction of the respective parts.

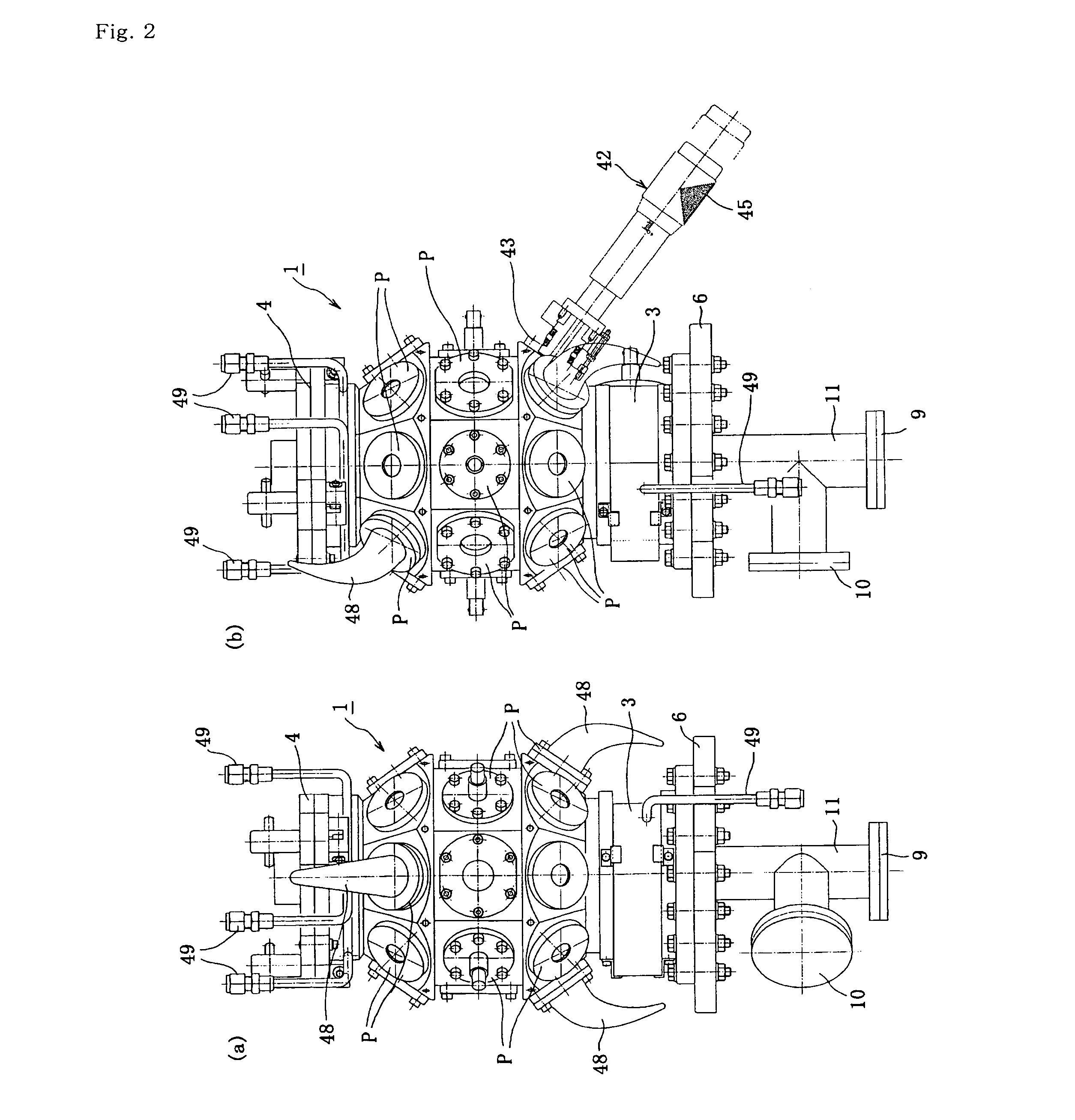

[0049]An electrostatic levitation furnace 1 shown in FIGS. 1 to 3 is provided with a vacuum chamber 3 forming a space 2 having nearly cylindrical shape opened in the vertical direction, a cover plate 4 for blocking the upper side of the vacuum chamber 3 in airtight, an electrode-base fixing pedestal 5 having a pipe-like shape and inset coaxially from lower side of the vacuum chamber 3, and a fitting flange 6 fixed to the underside of the vacuum chamber 3 in airtight, and this furnace 1 is secured to a base plate 51 shown with two-dot chain lines through the fitting flange 6.

[0050]The vacuum chamber 3 has an octagonal section and a sidewall divided into three parts in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com