Load torque blocking device

a technology of load torque and blocking device, which is applied in the direction of interengaging clutches, motor/generator/converter stoppers, dynamo-electric converter control, etc., can solve the problems of increased heating at high rpm, poor efficiency, and high frictional losses, so as to improve the efficiency of such a system and improve the overall degree of system efficiency , the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

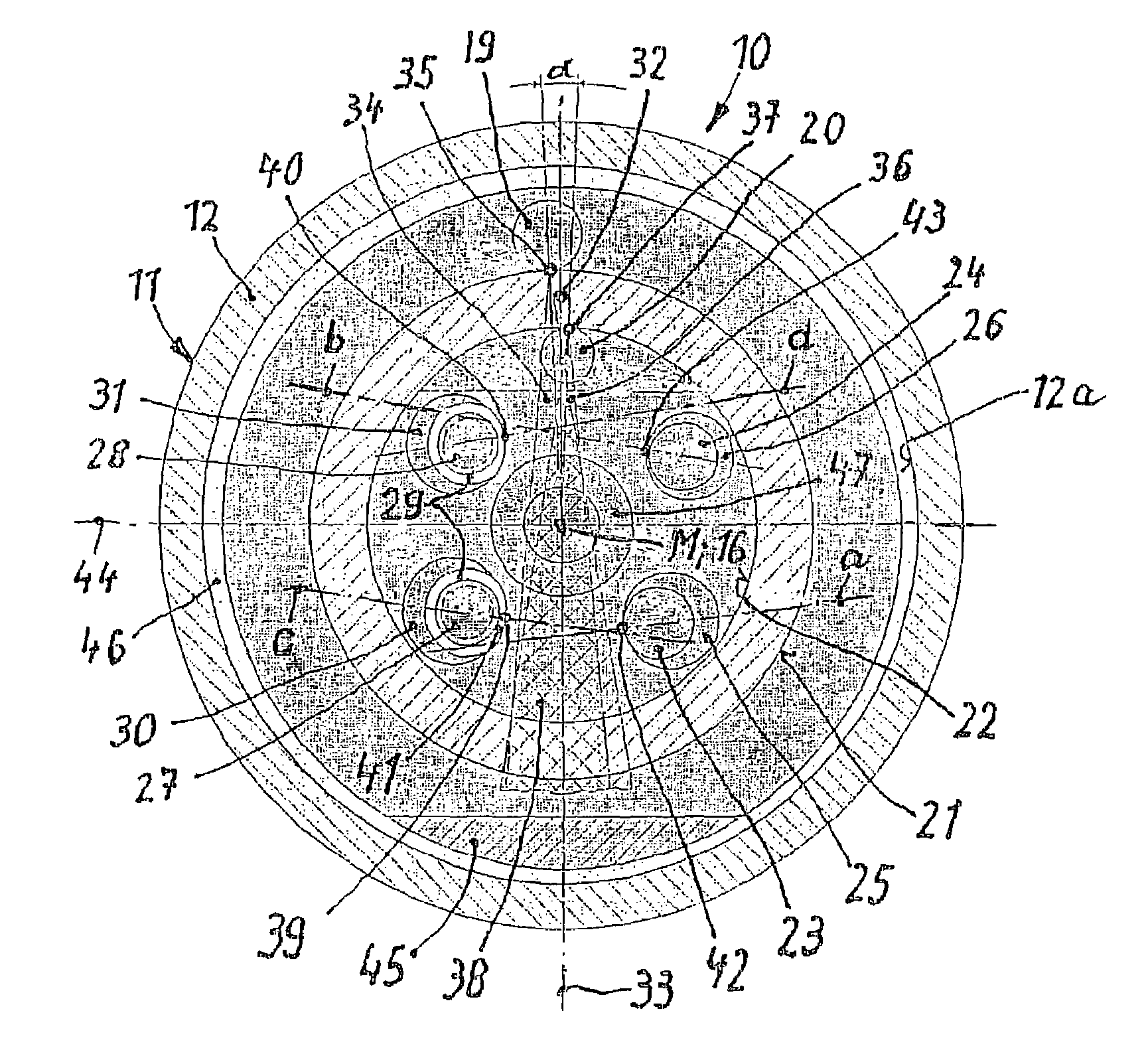

[0029]FIGS. 1 and 2 show a cross-section or longitudinal section of load torque lock 10 in accordance with the invention. It has a stationary housing 11 fixed to a frame with an external cylindrically embodied housing wall 12 and flange-like front sides 11a and 11b, on which a drive shaft 14 with a flange-like end 14a is pivoted on the one side 11a and an output shaft 15 with a flange-like end 15a is pivoted on the other side 11b. The drive shaft and output shaft 14, 15 lie on a common axis of rotation 16. Arranged between their spaced-apart, flange-like ends 14a, 15a is a locking body in the form of a locking disk 17 in a housing 11, which cooperates via locking means with locking rings fixed with the housing. The locking rings are embodied in the exemplary embodiment as a locking ring walls 18 projecting from the two front sides 11a, 11b of the housing 11 towards the inside until in front of the locking disk 17 and concentric to the axis of rotation 16. Serving as locking elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com