Elastic laminate including nonwoven layer formed from highly-oriented-component fibers and disposable garment employing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

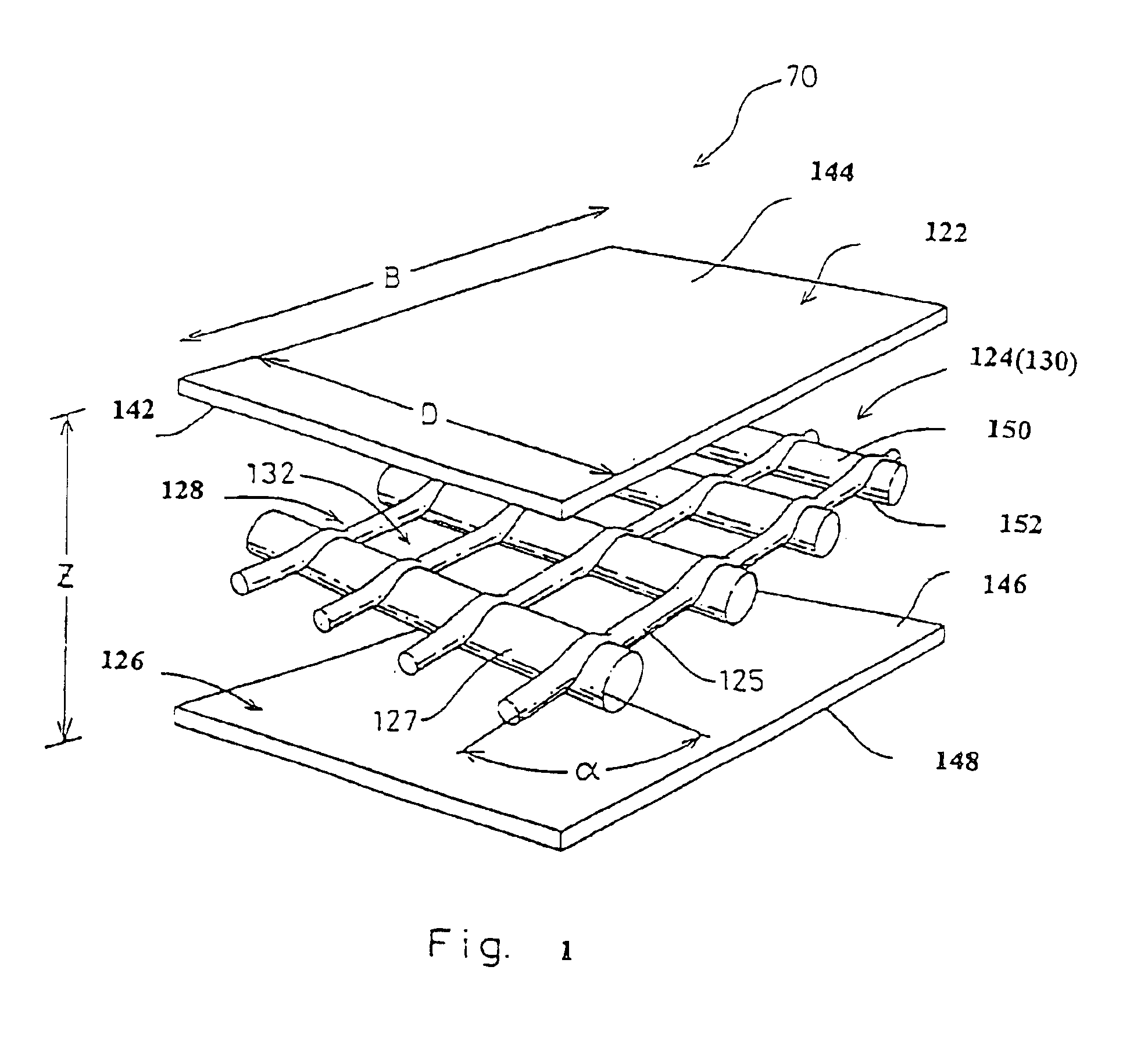

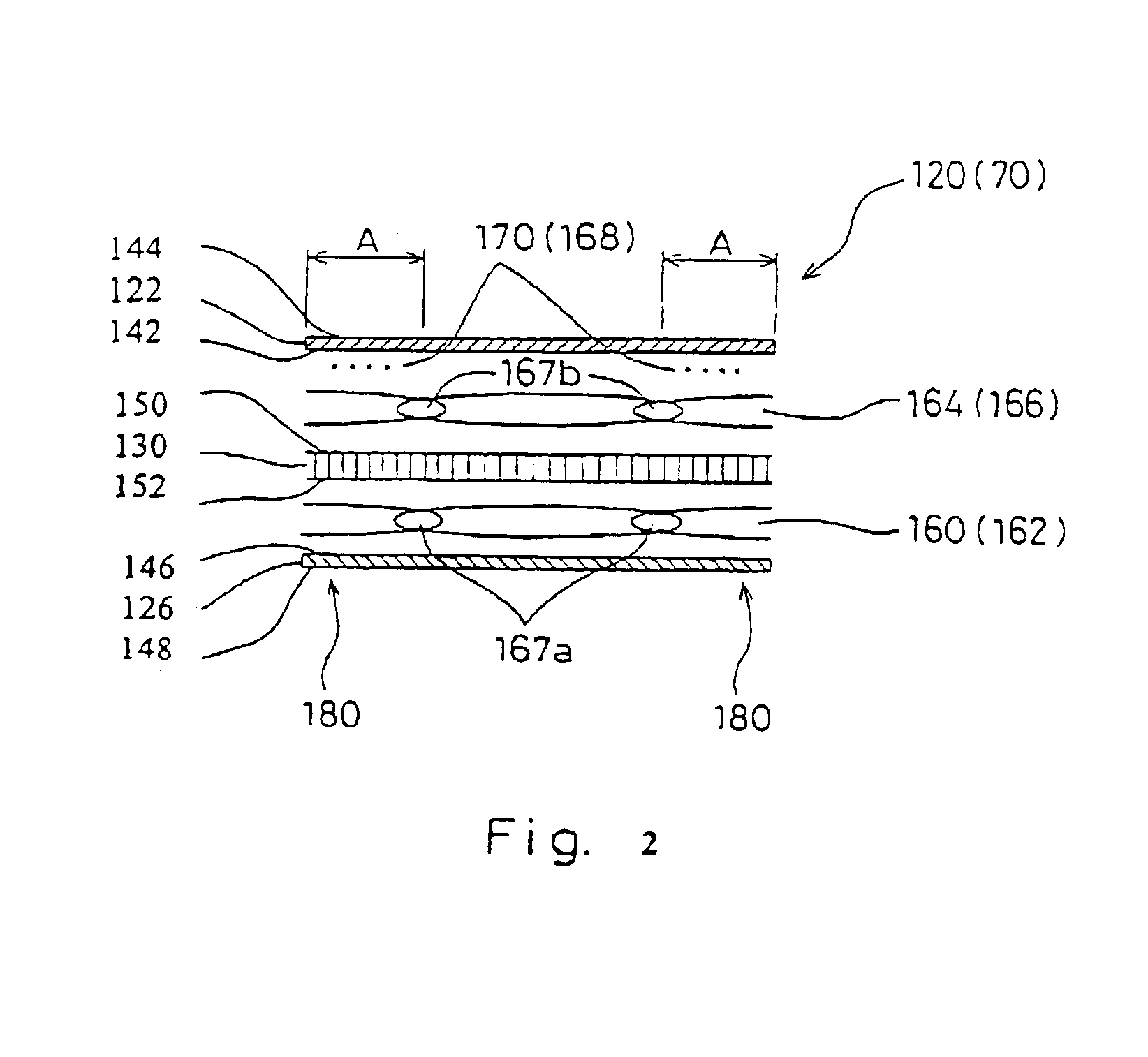

Image

Examples

Embodiment Construction

All cited references are incorporated herein by reference in their entireties. Citation of any reference is not an admission regarding any determination as to its availability as prior art to the claimed invention.

Herein, “comprise”, “include” and “have” mean that other element(s) and step(s) which do not affect the end result can be added. These terms encompass the terms “consisting of” and “consisting essentially of”.

Herein, “gf” stands for gram force.

Herein, “joined” or “joining” encompasses configurations whereby an element is directly secured to another by affixing the element directly to the other element, and configurations whereby the element is indirectly secured to the other element by affixing the element to intermediate member(s) which in turn are affixed to the other element.

Herein, “layer” does not necessarily limit the element to a single stratum of material in that a layer may actually comprise laminates or combinations of sheets or webs of materials.

Herein, “nonwove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com