Interpenetration apparatus for meausurement of underground blasting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

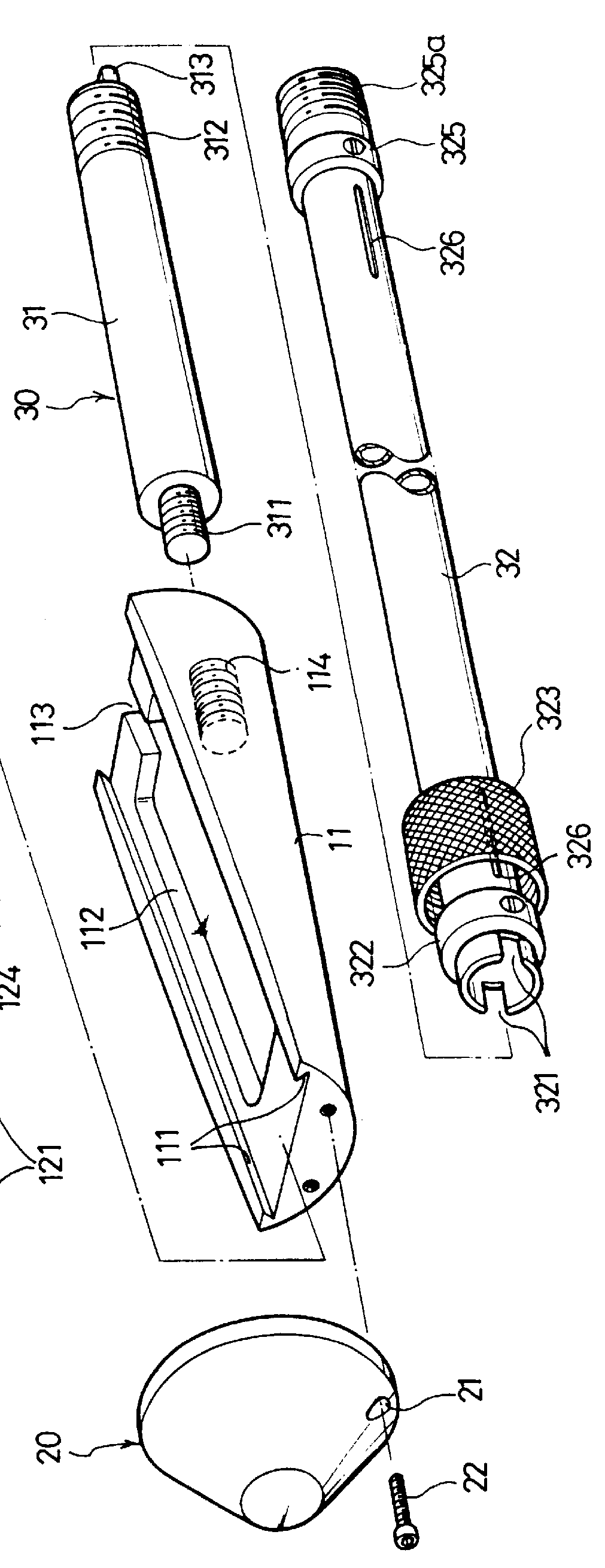

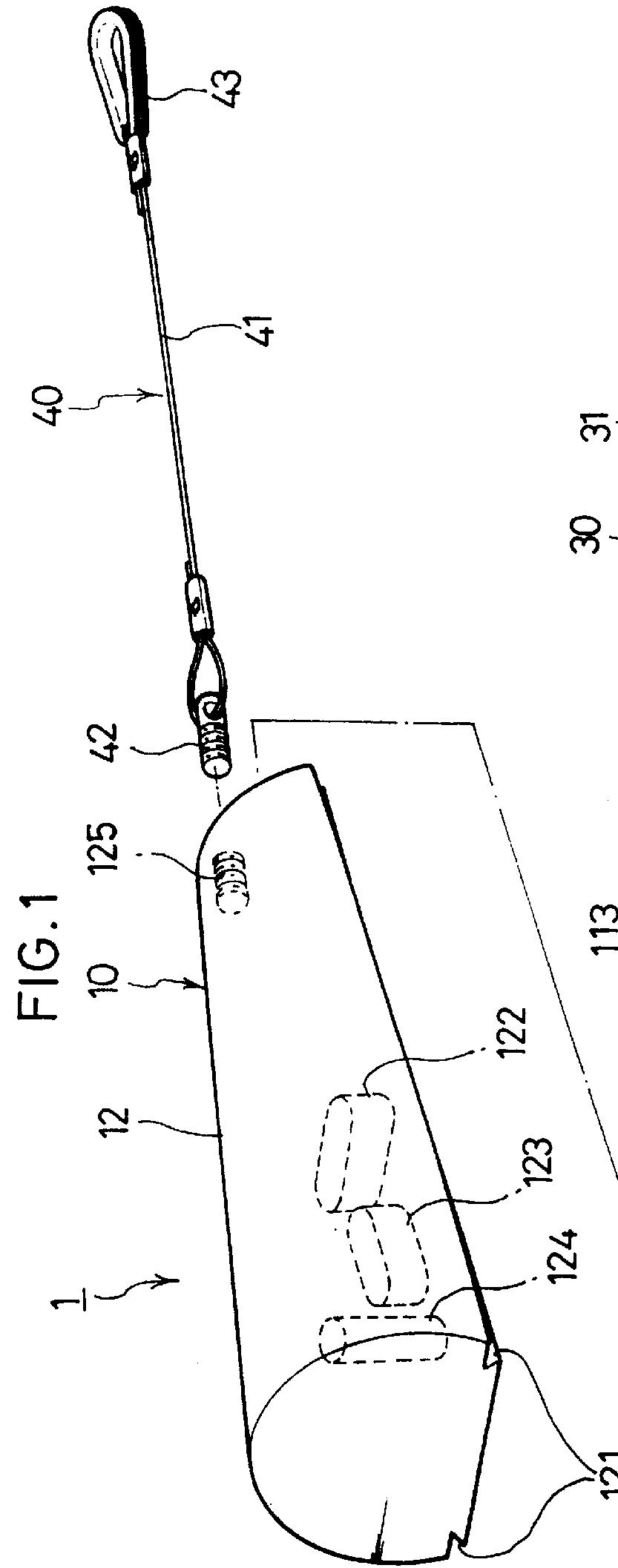

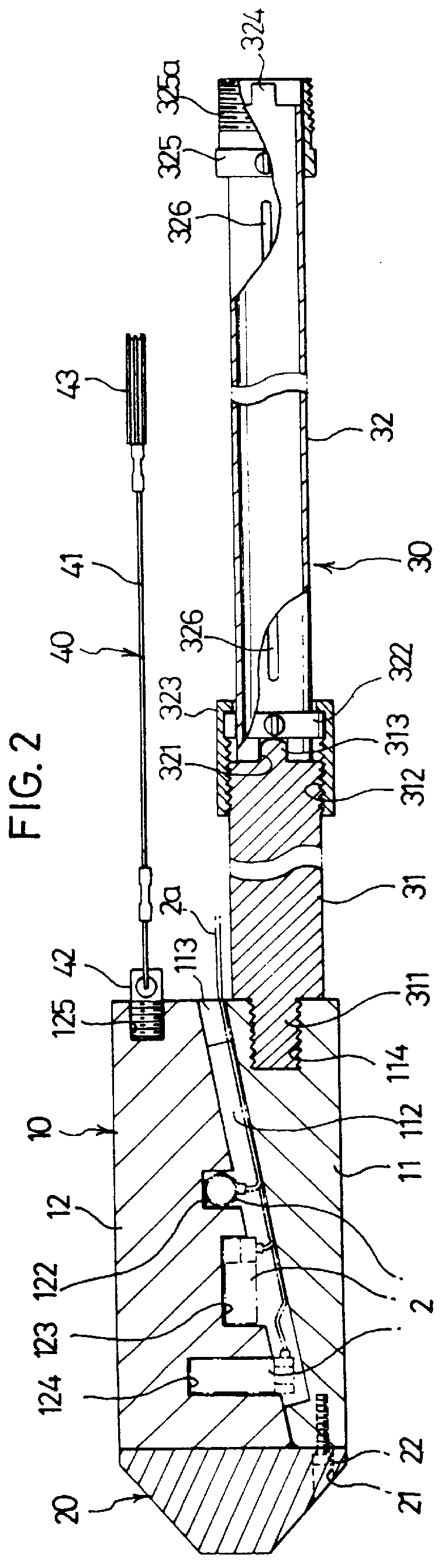

An interpenetration apparatus comprises a housing 10 divided into a fixture 11 and a mover 12, which are assembled into each other to form a cylinder and receive sensors 2 therein. The fixture 11 and the mover 12 are symmetrically cut in a longitudinal direction with respect to the housing 10 so that the chord length at one end surface of the fixture 11 is approximately equal to that at the other end surface of the mover 12. The fixture 11 includes slant guide grooves 111 longitudinally cut to be stepped at both ends thereof, a passage 113 formed at the end thereof to guide a cable into the housing 10 and a space 112 concaved in the bottom surface of the fixture 11 to receive the cable. The mover 12 includes a slant inserting embossment 121 stepped in a longitudinal direction to couple with the slant guide groove 111; and three receptacles 122, 123 and 124 respectively formed to receive sensors for detecting the blasting vibrations in X, Y and Z directions, respectively, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com