Bicycle driving system and kit

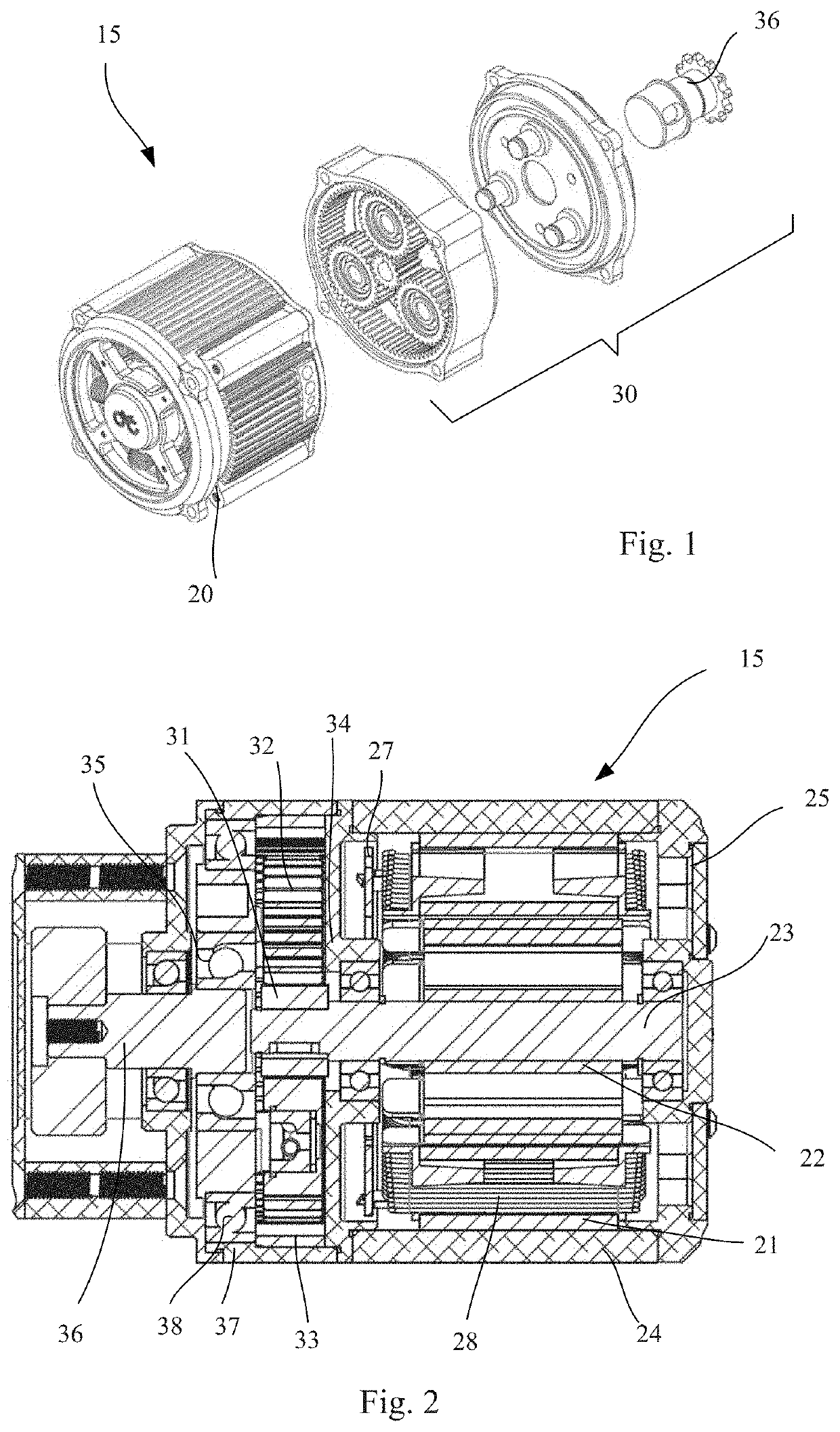

a technology of auxiliary mid-drive system and bicycle frame, which is applied in the direction of cycle equipment, transportation and packaging, gearing, etc., can solve the problems of poor compatibility between the bicycle frame, insufficient ground clearance, and limited orientation of the auxiliary mid-drive system on the bottom bracket of the bicycle fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080]The invention will be further described below in conjunction with the specific embodiments and the drawings. More details are set forth in the following description for better understanding of the invention, although it is apparent that the invention may be embodied in various manners other than those described herein. Those skilled in the art may make extension and deduction depending on the practical application situations without departing from the spirit of the invention. Thus, the scope of the invention is not intended to be limited by the contents of the specific embodiments.

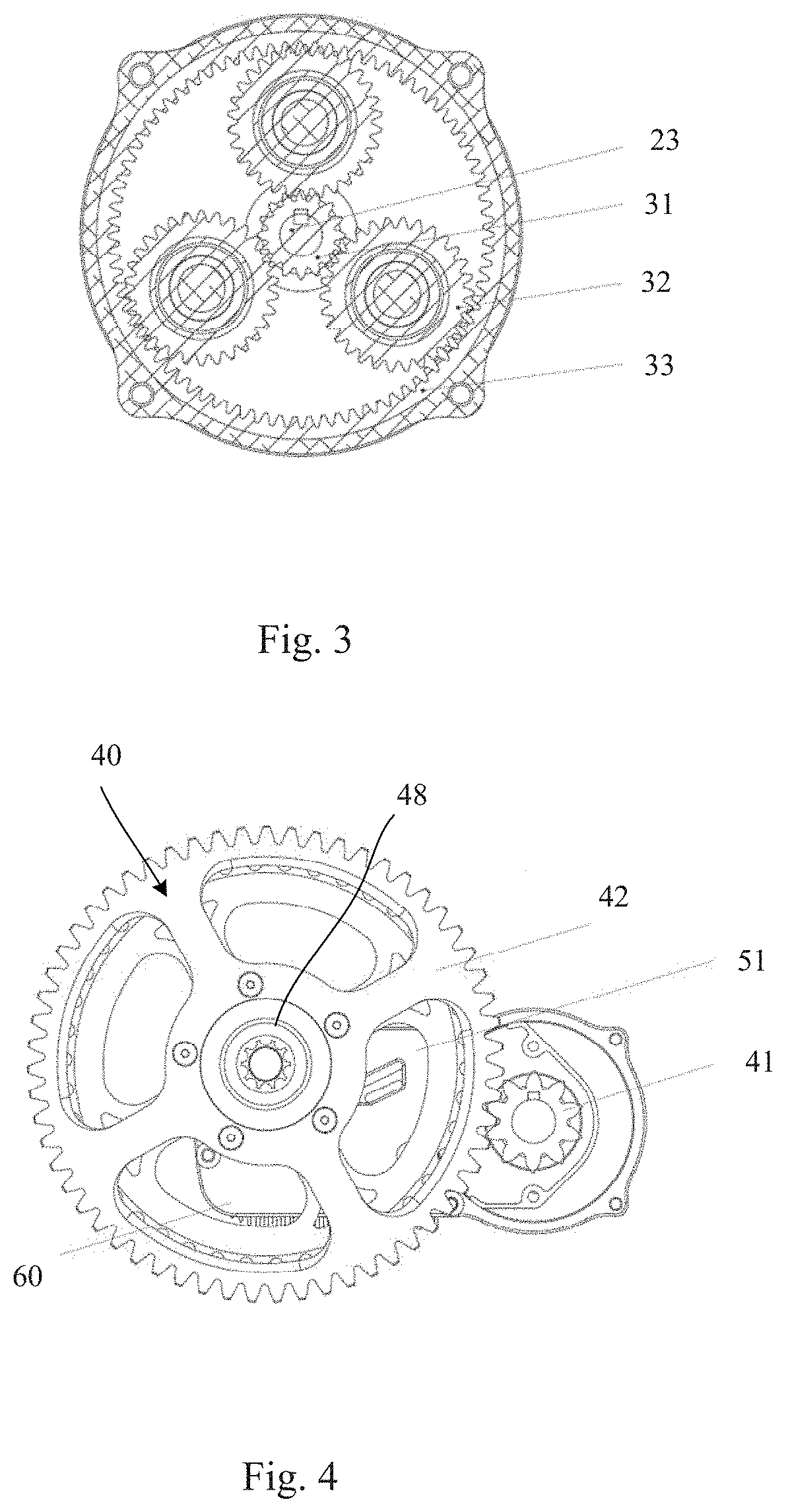

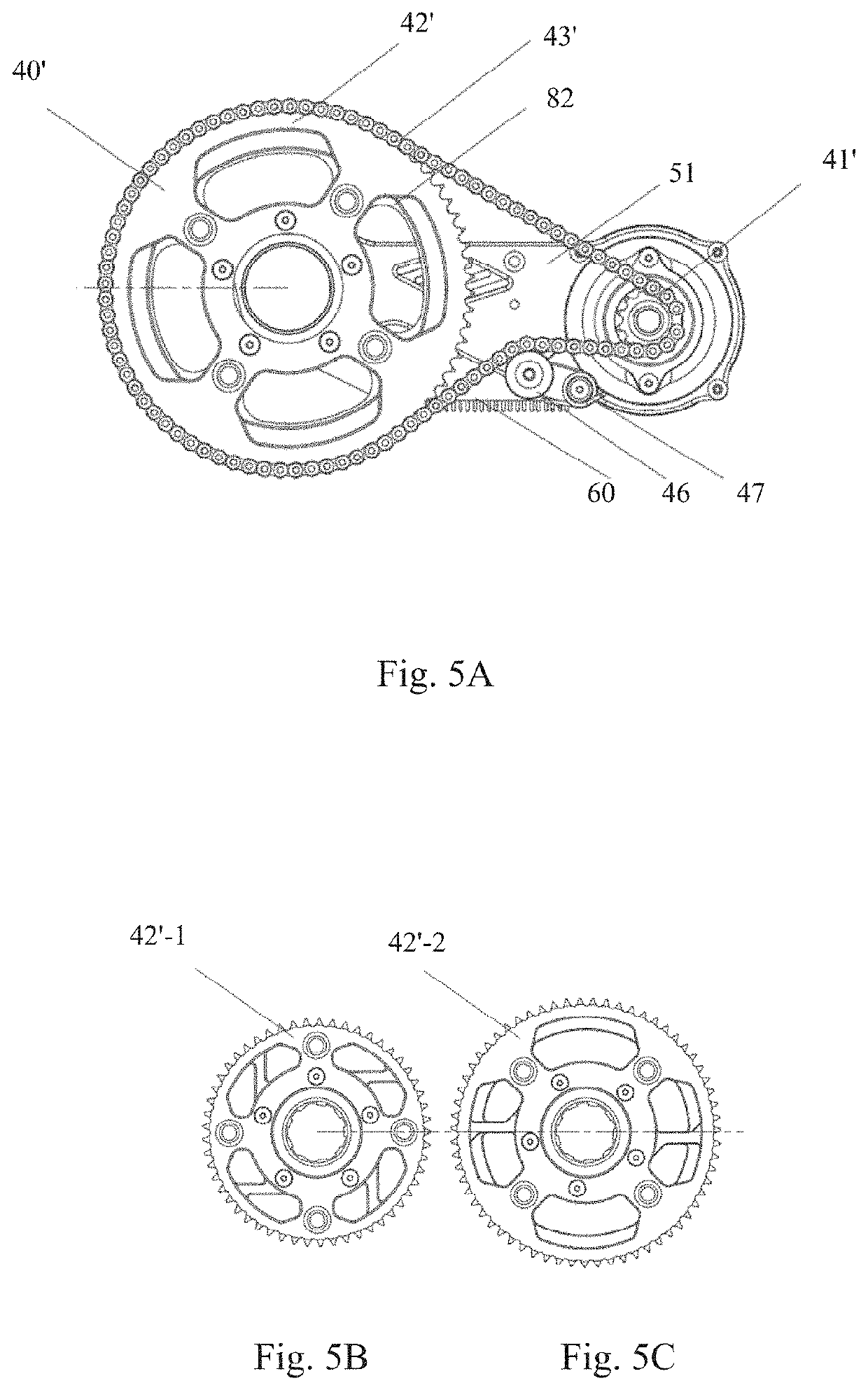

[0081]A common power component in a bicycle is a pedal assembly 80. The pedal assembly 80 usually comprises a pedal, crank 81, chainrings 82 and a spindle 83 (which is also called a BB spindle) mounted on a mounting part of a bottom bracket of the bicycle. The pedaling of a rider drives the crank 81 and the chainrings 82 to rotate. The rotation of the chainrings 82 is transferred through a chain to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com