Beverage Container

a beverage container and glass technology, applied in the field of beverage containers, can solve the problems of foam creation, inconsistent outward flow of beverage, consumers often failing to create a second aperture in the wall of existing beverage containers, etc., to facilitate the quick, efficient and controlled rupturing of the side wall, and facilitate the rapid and smooth dispensing of carbonated beverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

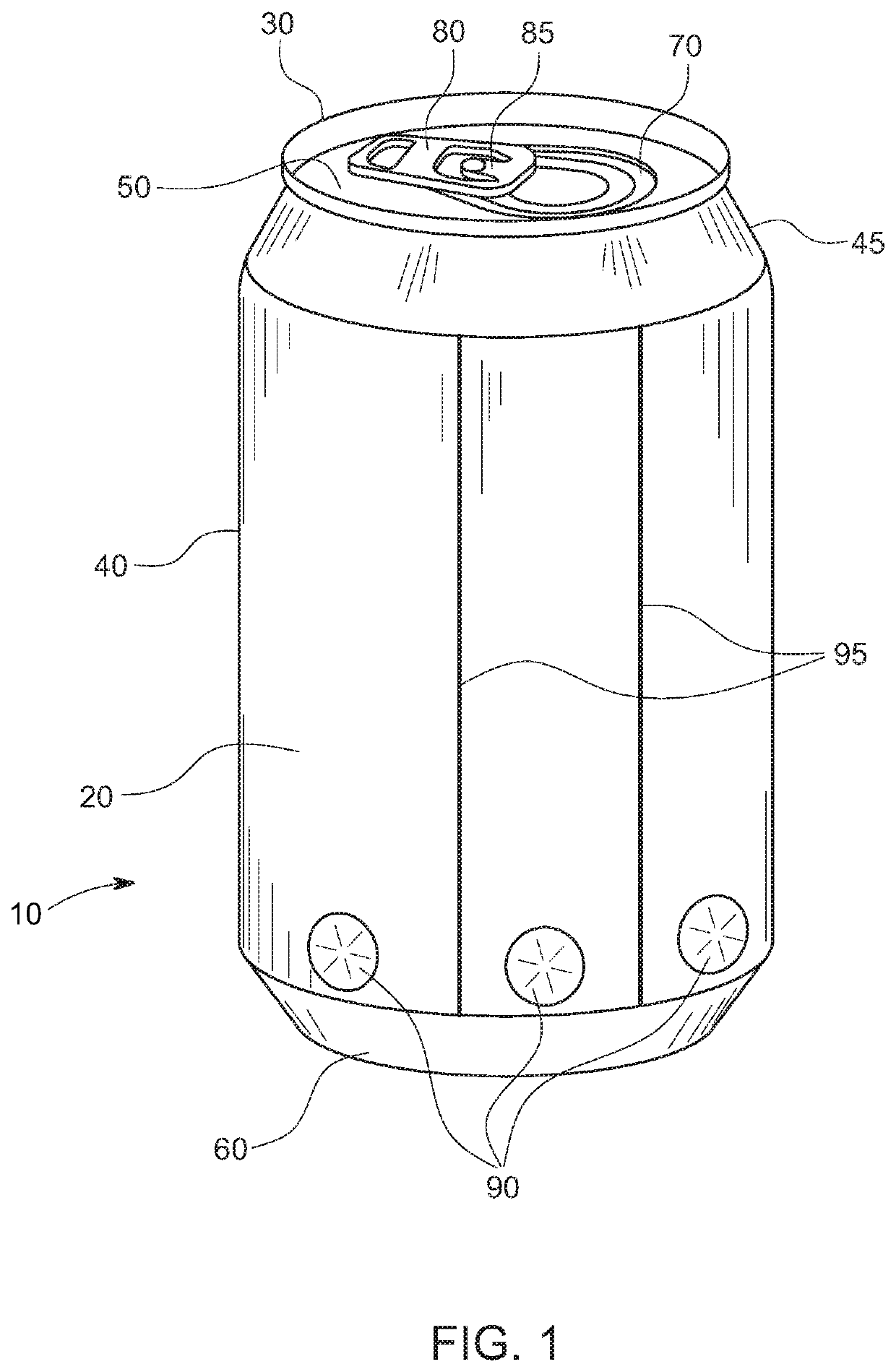

[0018]Referring now to FIG. 1, a dimpled-wall beverage container 10 is shown, according to the present invention, comprising a container 20 of traditional cylindrical configuration, constructed of aluminum or other metal, and used to hold beverages, particularly carbonated beverage. The container 20 consists of a container rim 30, container body 40, a container top or lid 50 and container bottom 60, as found in traditional beverage containers of this sort. The body 40 of the can is commonly narrowed to form a neck 45 to accommodate a lid 50 having a smaller radius than the body 40 to reduce the amount of metal used in forming the container. The container bottom 60 commonly assumes a dome shape in order to resist internal pressure. The container top or lid 50 is commonly secured to the container body 40 through the flanged rim 30 formed by bending and seeming the lid 50 after filling of the body 40 with the beverage. Located along the container top or lid 50 is a traditional beverage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com