Cooling system with thermal storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

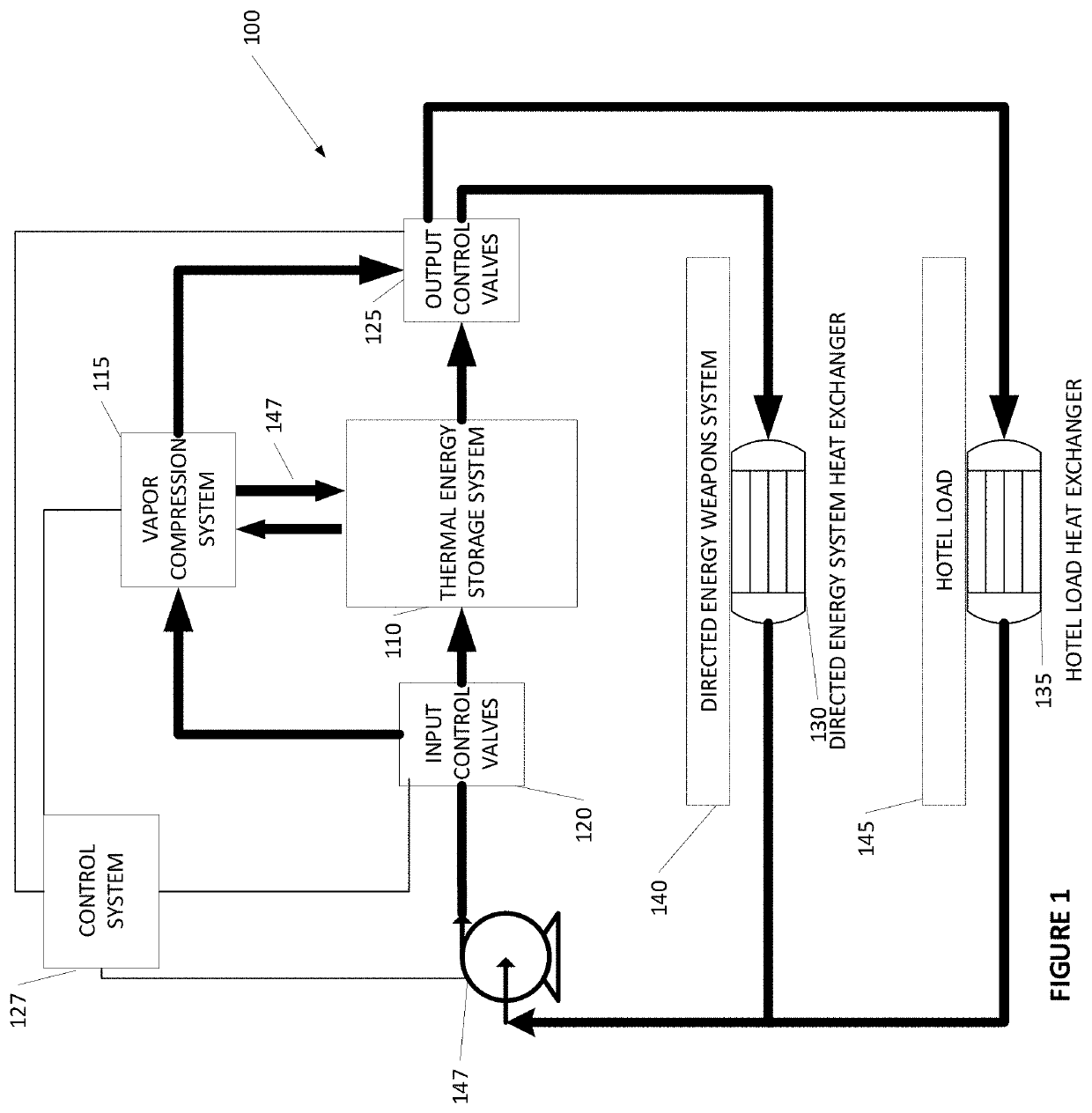

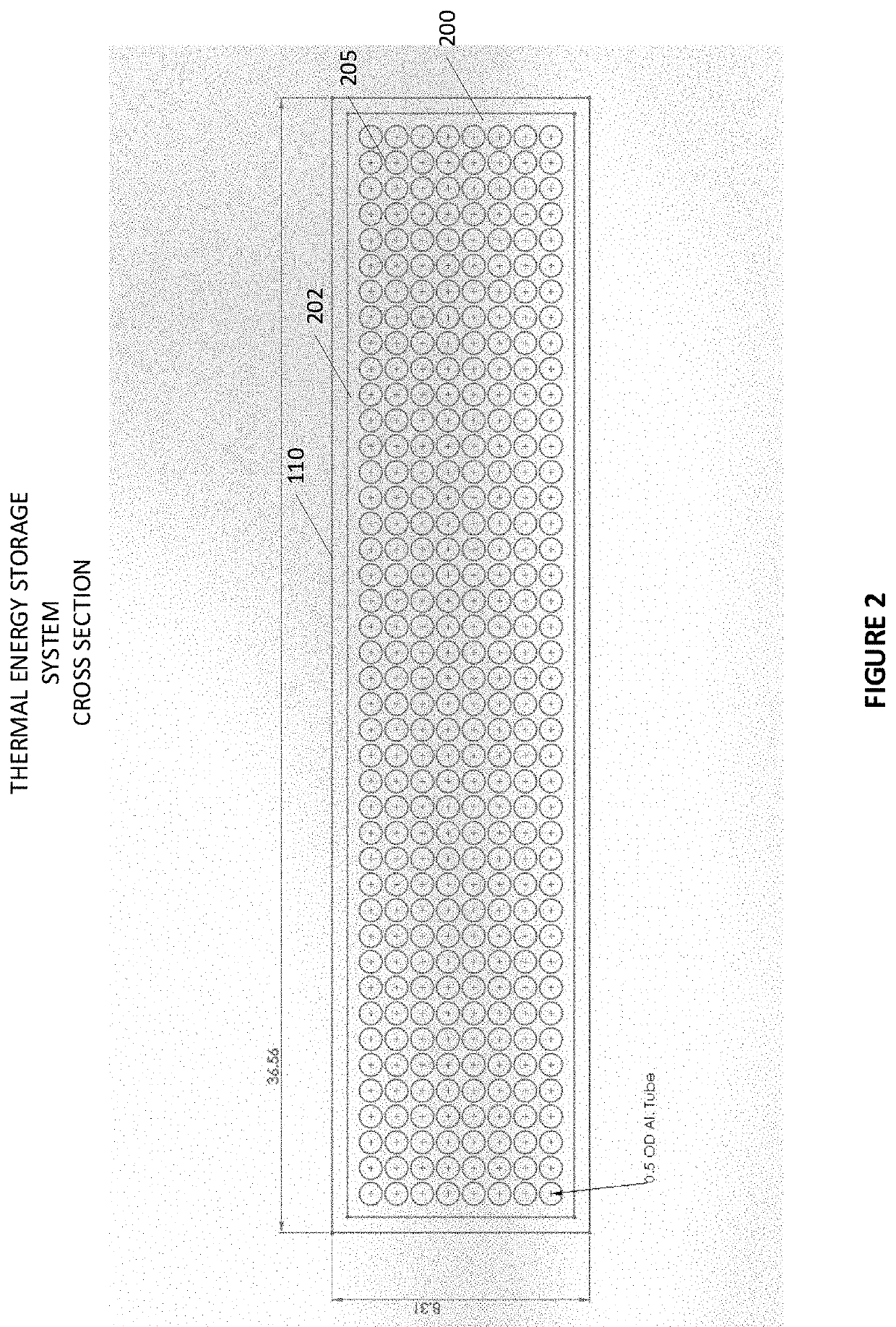

[0091]A thermal energy storage system is made that is capable of cooling a laser weapon that outputs 100 kW of heat. In this example, the laser outputs bursts of energy over a 120 second period and then stays deactivated for 280 seconds. The thermal energy storage system uses an enclosure that contains heat transfer tubes of potassium fluoride tetrahydrate as the phase change material. A 100 kW heat load from a laser that is active over a 120 second period generates 12,000 kJ of heat energy that needs to be dissipated. Potassium fluoride tetrahydrate is able to store 230 kJ / kg of material, thus the thermal energy storage system is made from 52.2 kg of potassium fluoride tetrahydrate to absorb 12,000 kJ of heat energy.

[0092]The material density of potassium fluoride tetrahydrate is 1455 kg / m3 so that 52.1 kg of material requires a volume of 0.0359 m3 of space within the heat transfer tubes located inside the thermal energy storage system enclosure.

[0093]A vapor compression system wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com