Apparatus for collecting samples of drill cuttings and method of use

a drill cutting and apparatus technology, applied in the field of automatic process of collecting drill cuttings, can solve the problems that the throughput and functionality of these measurements may not be adequate to support the drilling process, and none of the prior art above addresses the practical aspects of drill cutting sampling and preparation needed to enable quantitative high throughput measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

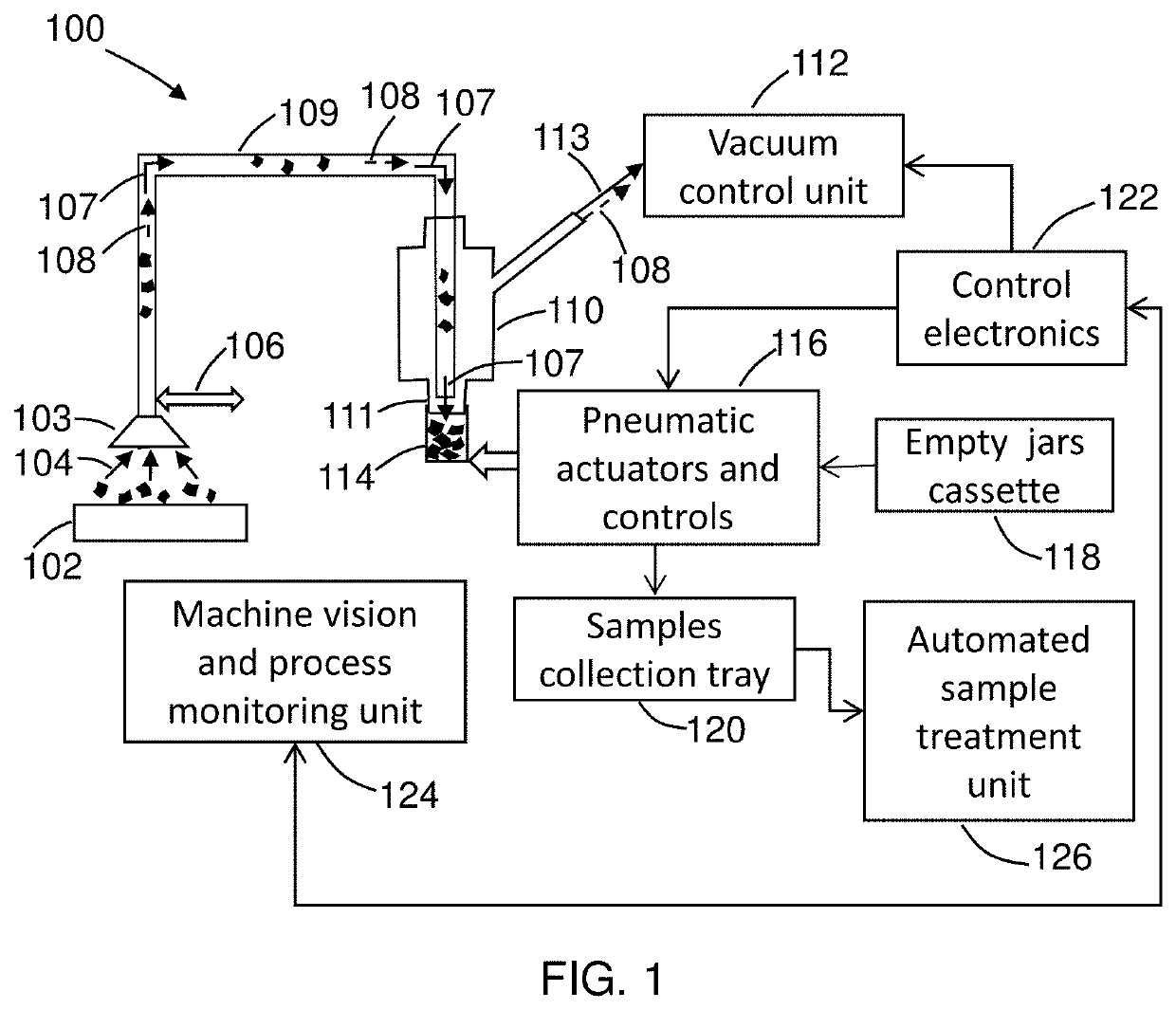

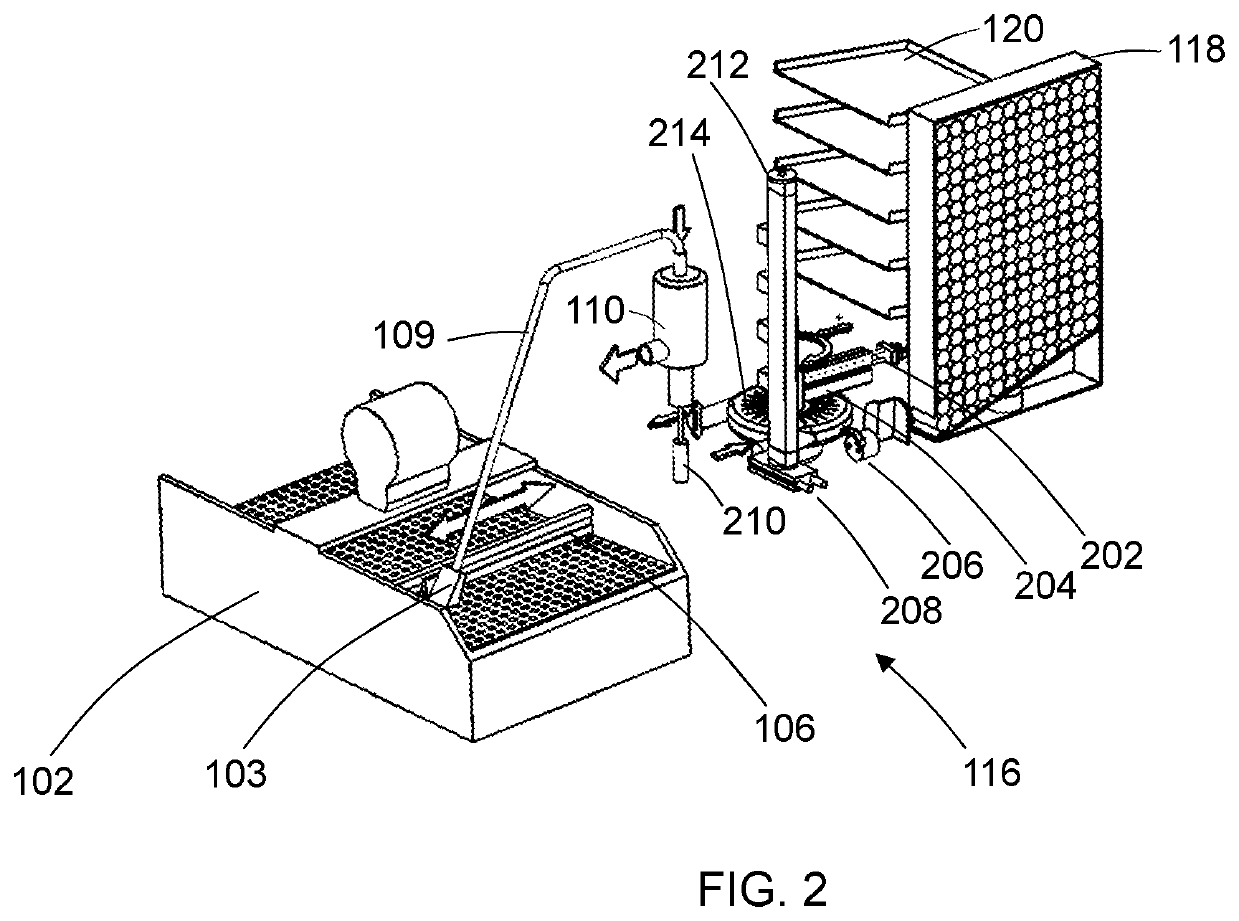

[0014]FIG. 1 illustrates a conceptual view of the apparatus of the present invention. The apparatus comprises a cuttings transfer unit 100 including a cuttings inlet port 103 to acquire cuttings from the surface of a shaker 102 or, alternatively, from a cuttings receiving board (the cuttings entering the inlet port are shown at 104), a cuttings inlet port displacement actuator 106 to scan the surface of the shake during the cuttings acquisition from the shaker surface, and an adjustable suction line 109 (flexible, with adjustable length) to transfer cuttings from the inlet port to the discharge chamber 110. The adjustable suction line is also used to substantially eliminate (or reduce as needed) moisture on the surface of the cuttings fragments. The moisture is reduced during transferring cutting in the suction line. The length of the line controls the level of the moisture reduction. The moisture control is required for some measurements on drill cutting, for example, for nuclear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com