Riser gas handling system and method of use

a gas handling system and gas handling technology, applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of uncontrollable gas release, difficulty or inability to perform conventional drilling, and difficulty in achieving well control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

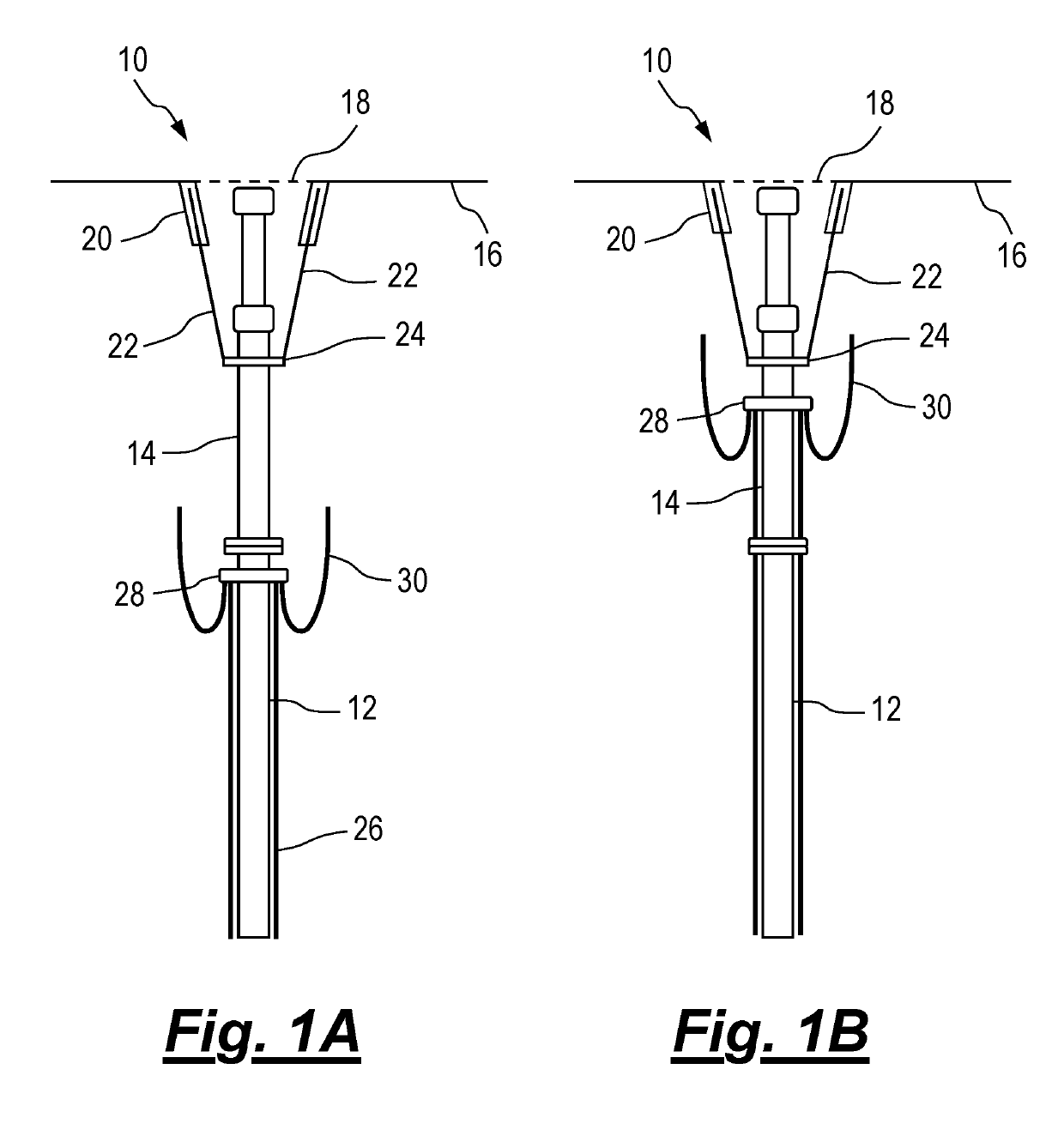

[0207]FIGS. 1A and 1B show features of conventional drilling riser assemblies for extracting oil and natural gas from a subsea reservoir known in the prior art.

[0208]The riser assembly 10 comprises a riser 12 located between a rig platform 16 and a blowout preventer (BOP) assembly (not shown) secured to the top of the wellhead. The riser 12 is connected to a slip joint 14. The slip joint 14 is configured to respond to heave movement of the platform 16 during dynamic sea conditions.

[0209]A portion of platform 16 is shown, which may be a floating rig or drillship. The platform supports the riser assembly 10 and comprises a moon pool opening 18. A plurality of tensioning cylinders 20 are secured to the platform and exert an upward force on rods or cables 22. The lower end of each rod or cable 22 is connected to a riser tensioning ring 24 which is connected to maintain the stability of the riser 12 in the offshore environment.

[0210]External auxiliary lines 26 are connected to the BOP (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com