Hydraulic rotary machine and valve plate thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

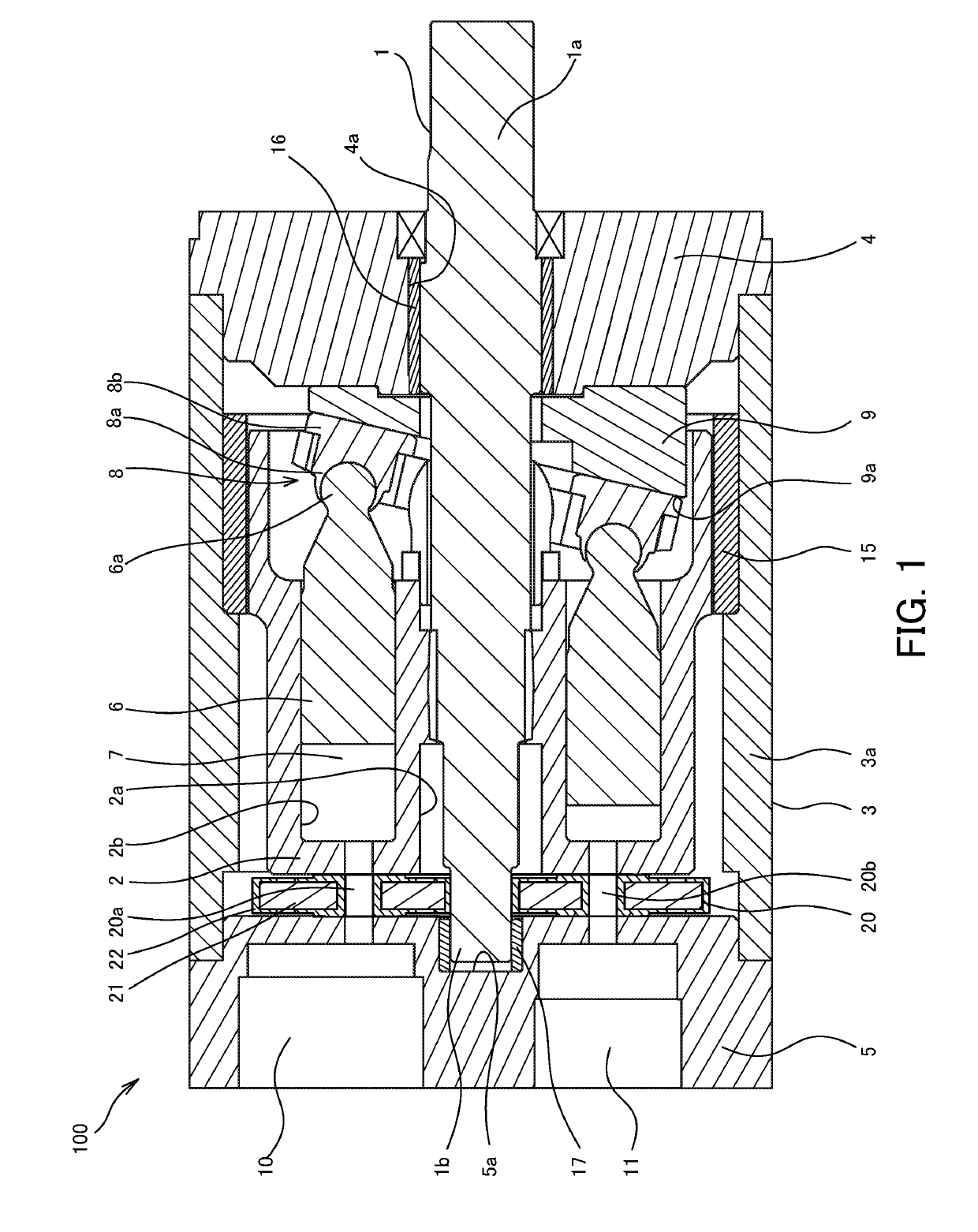

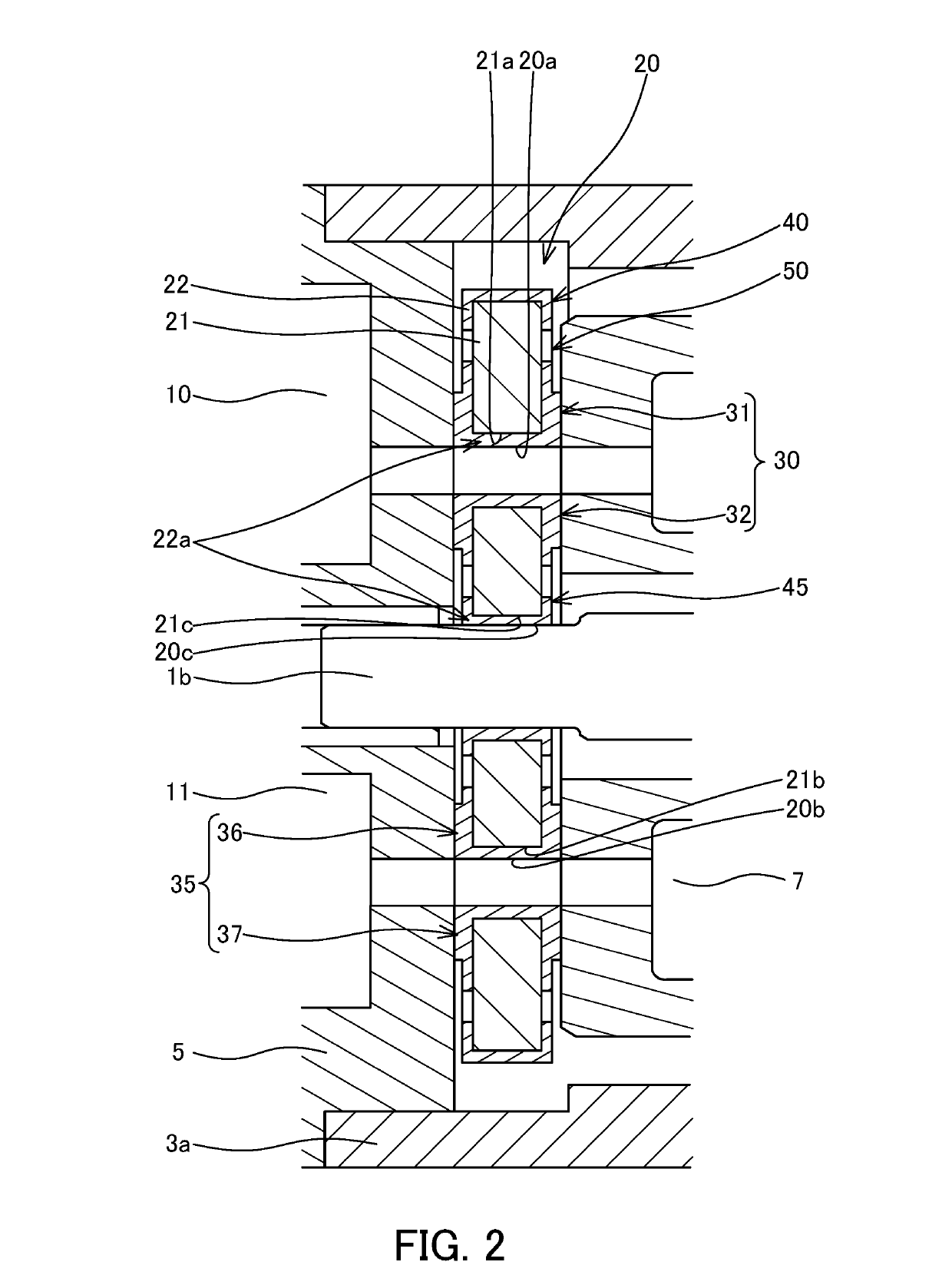

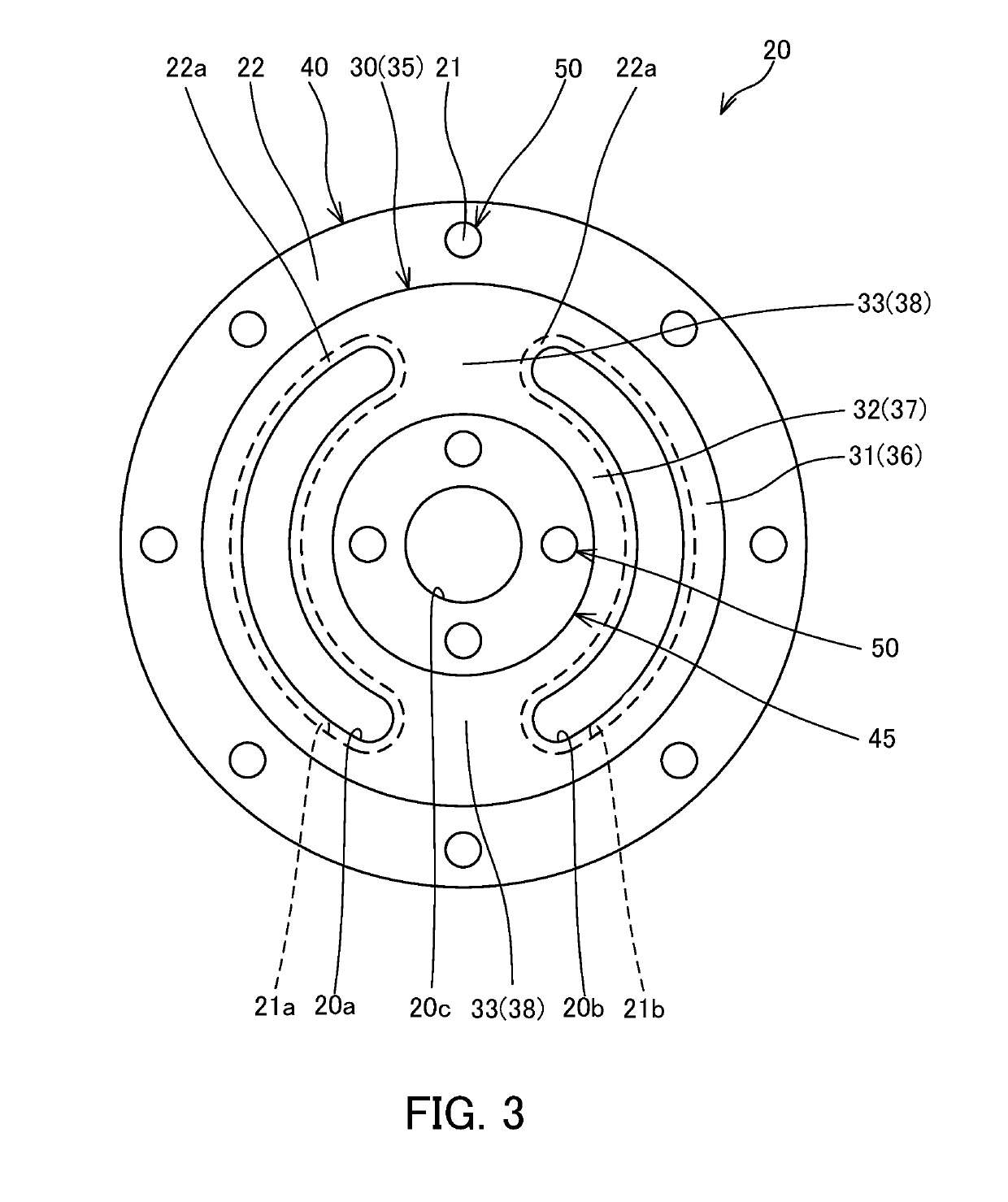

[0019]First, by referring to FIGS. 1 to 7, a hydraulic rotary machine according to a first embodiment of the present invention will be described.

[0020]In the first embodiment, a case where the hydraulic rotary machine is a water-pressure rotary machine 100 using water as an operating liquid will be described. The water-pressure rotary machine 100 functions as a piston pump capable of supplying water as the operating fluid when a shaft 1 is rotated by power from an outside and a piston 6 is reciprocated and also functions as a piston motor capable of outputting a rotary driving force when the piston 6 is reciprocated by a fluid pressure of the water supplied from the outside and the shaft 1 is rotated. The water-pressure rotary machine 100 may function only as a piston pump or may function only as a piston motor.

[0021]In the description below, the case where the water-pressure rotary machine 100 is used as a piston pump is exemplified, and the water-pressure rotary machine 100 is cal...

second embodiment

[0074]Subsequently, a piston pump 200 according to a second embodiment of the present invention will be described by referring to FIGS. 8 to 10. In the following, points different from the first embodiment will be mainly described, and the same reference numerals are given to the same constitutions as those in the piston pump 100 in the aforementioned first embodiment, and explanation will be omitted.

[0075]In the aforementioned first embodiment, the exposed portion 50 is provided on a part of the outer-side non-contact portion 40 and also provided on a part of the inner-side non-contact portion 45. Instead of this, a valve plate 120 of the piston pump 200 is different from the aforementioned first embodiment in a point that all of an outer-side non-contact portion 140 is formed as an exposed portion, and all of an inner-side non-contact portion 145 is formed as an exposed portion.

[0076]As illustrated in FIGS. 8 and 9, the valve plate 120 of the piston pump 200 has the outer-side non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com