Packaging system and blanks therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

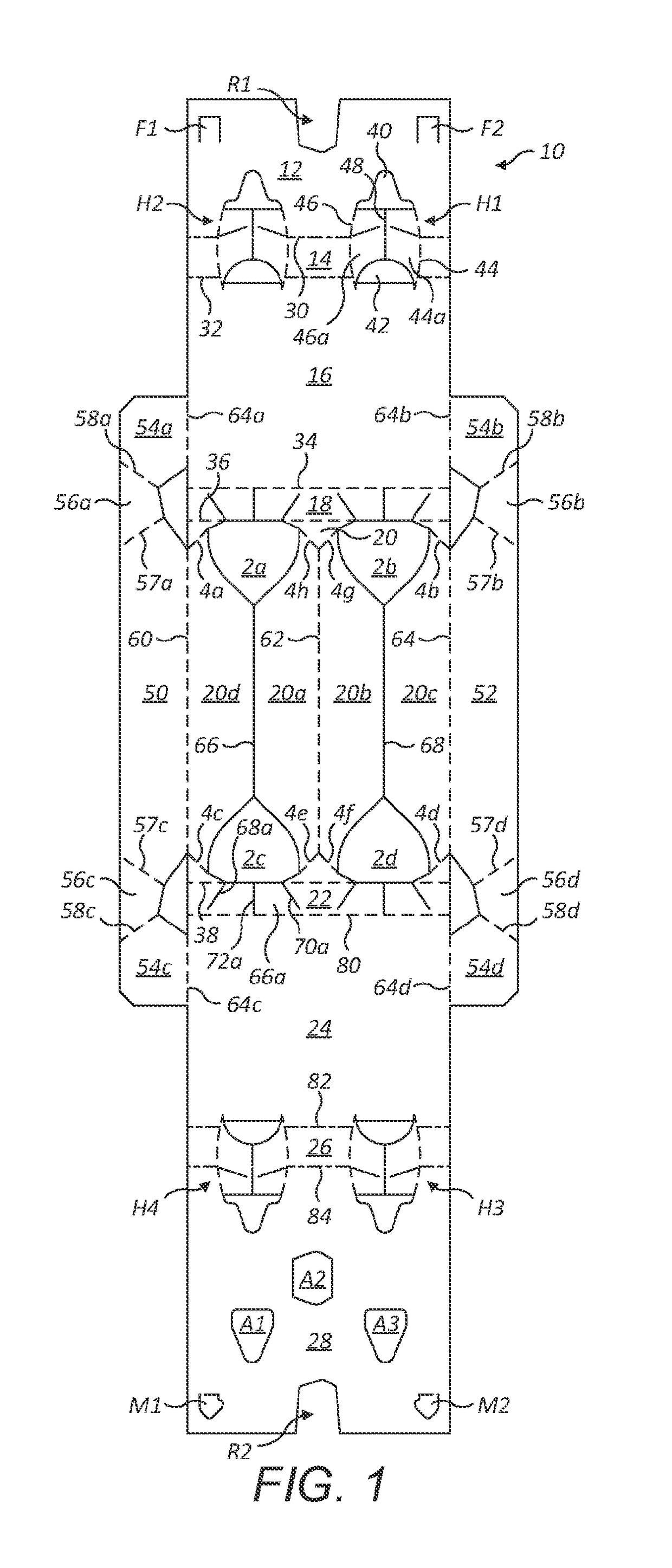

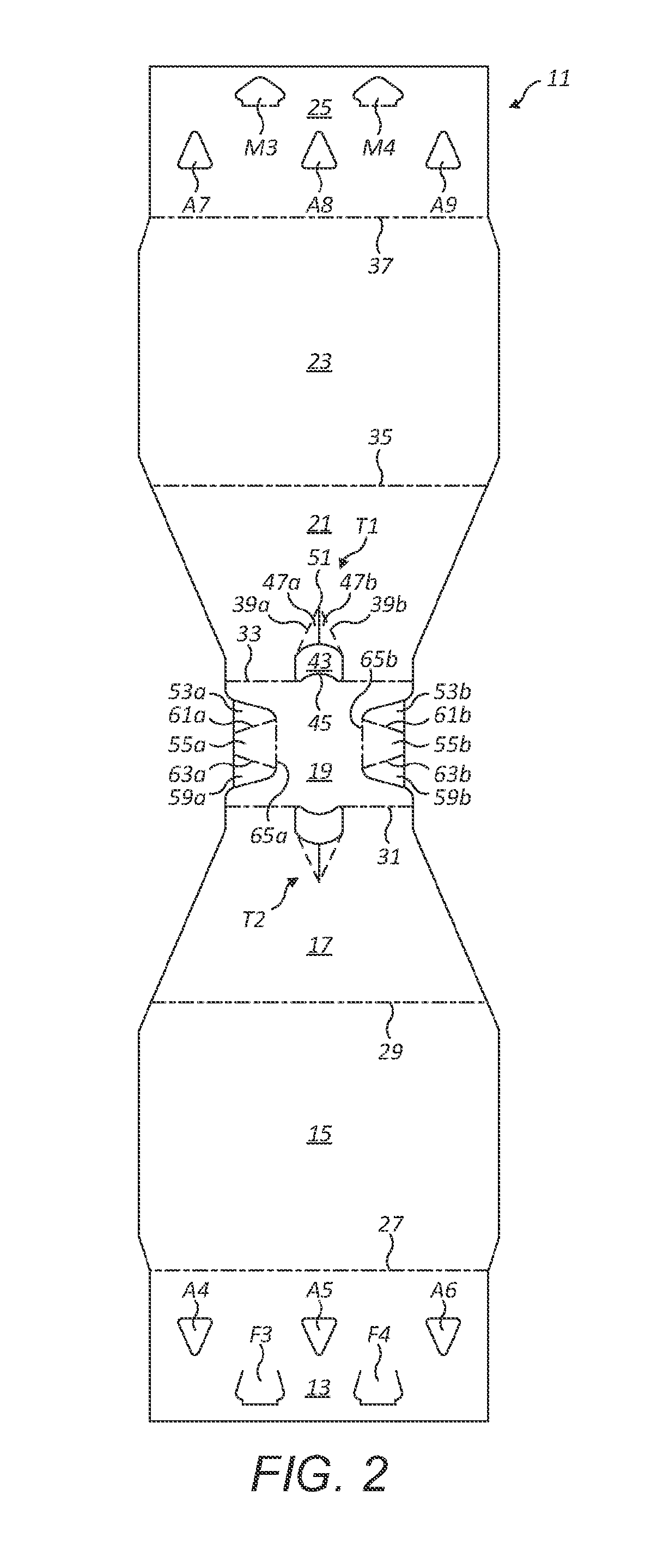

[0084]Referring now to FIG. 1, there is shown a plan view from above of a first inner blank 10 according to the disclosure. The first inner blank is optionally a wraparound style blank 10. The first inner blank 10 is suitable for being paired with a second outer blank, such as but not limited to, the second outer blank 11 shown in FIG. 2.

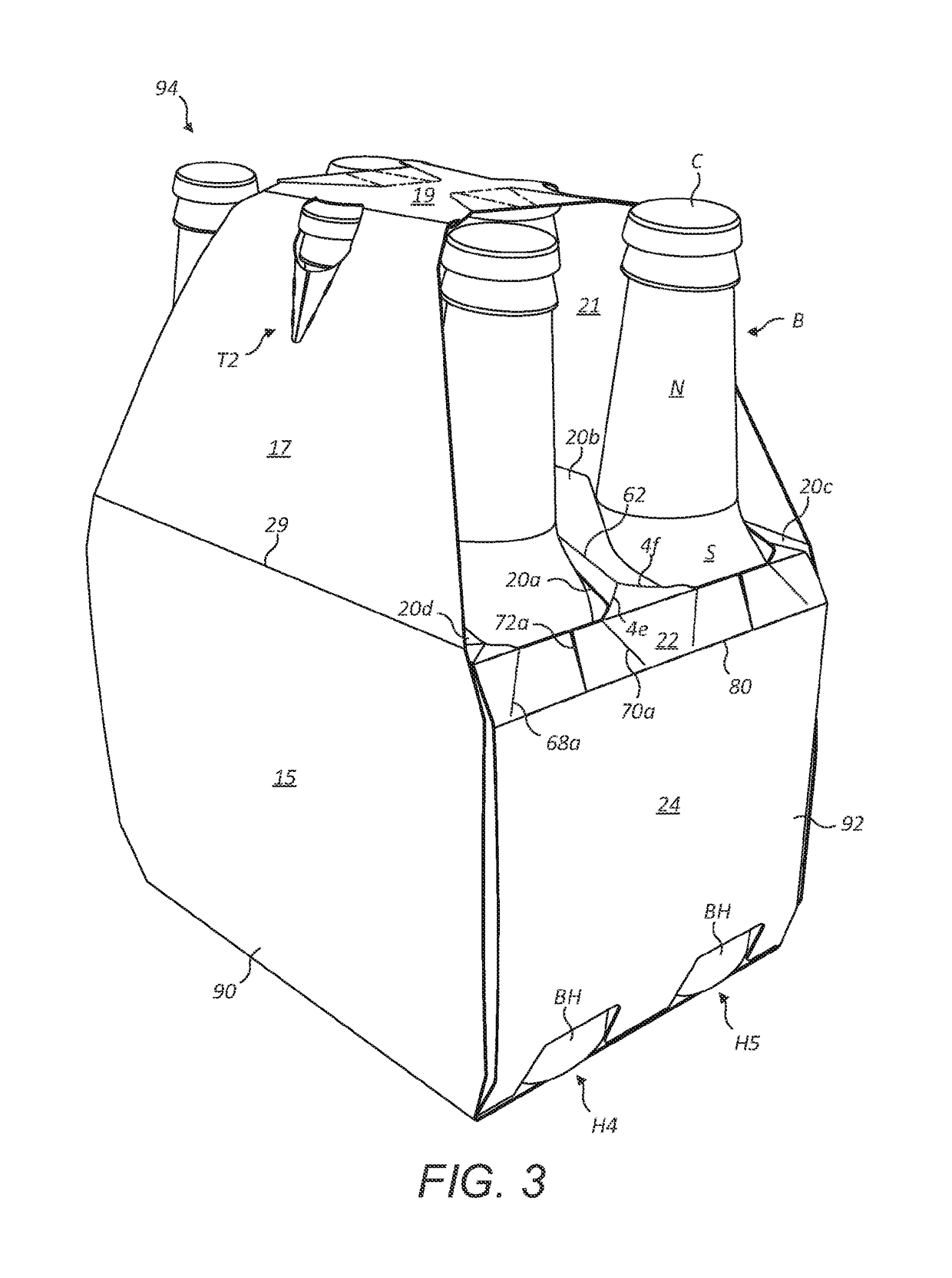

[0085]The first inner blank 10 comprises a series of main panels which form the main walls of a first inner carrier 92 once the first inner blank 10 is assembled. The series of main panels include: a first bottom panel 12, a first bevel panel 14, a first side panel 16, a second bevel panel 18, a top panel 20, a third bevel panel 22, a second side panel 24, a fourth bevel panel 26 and a second bottom panel 28. The main panels 12, 14, 16, 18, 20, 22, 24, 26, 28 are hinged one to the next in series along fold lines 30, 32, 34, 36, 38, 80, 82 and 84.

[0086]Additionally, first and second end panels 50, 52 are coupled to the top panel 20 by fold lines 60, ...

third embodiment

[0162]Referring now to FIG. 9, there is shown a plan view from above of a first inner blank 210 according to the disclosure. The first inner blank 210 is also optionally a wraparound style blank 210 and is suitable for being paired with a second outer blank, such as but not limited to, the second outer blank 11 shown in FIG. 2.

[0163]The first inner blank 210 again comprises a series of main panels which form the main walls of a first inner carrier 292 shown in FIGS. 10, 11 and 12. The series of main panels includes: a first bottom panel 212, a first bevel panel 214, a first side panel 216, a top panel 220, a second side panel 224, a fourth bevel panel 226 and a second bottom panel 228. The main panels 212, 214, 216, 220, 224, 226, 228 are hinged one to the next in series along fold lines 230, 232, 236, 280, 282 and 284.

[0164]The first inner blank 210 optionally does not comprise second and third bevel panels either side of the top panel 220, and also does not comprise any end panels...

fourth embodiment

[0177]Referring now to FIGS. 13 to 16, there is shown a further embodiment of the present invention wherein an inner blank 310 may be combined with a second outer blank 311 in order to construct an alternative package 394. In the fourth illustrated embodiment like numerals have, where possible, been used to denote like parts, albeit with the addition of the prefix “300” to indicate that these features belong to the This embodiment shares many common features with the previous embodiments and therefore only the differences from the embodiments illustrated in FIGS. 1 to 12 will be described in any greater detail.

[0178]A first inner blank 310 is shown in FIG. 14 comprising a series of main panels which form the main walls of a first inner carrier 392 once the first inner blank 310 is assembled. The series of main panels includes: a first bottom panel 312, a first bevel panel 314, a first side panel 316, a top panel 320, a second side panel 324, a second bevel panel 326 and a second bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com