Slurry for manufacturing graphene sheet combining graphite flake structure

a technology of graphene and slurry, which is applied in the direction of carbon-silicon compound conductors, coatings, chemistry apparatus and processes, etc., can solve the problems of affecting the properties of electronic components, unable to fit the irregular shape of the heat source, and electronic components may have permanent damage, etc., to achieve good heat conductivity, improve heat conductivity, and improve heat conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

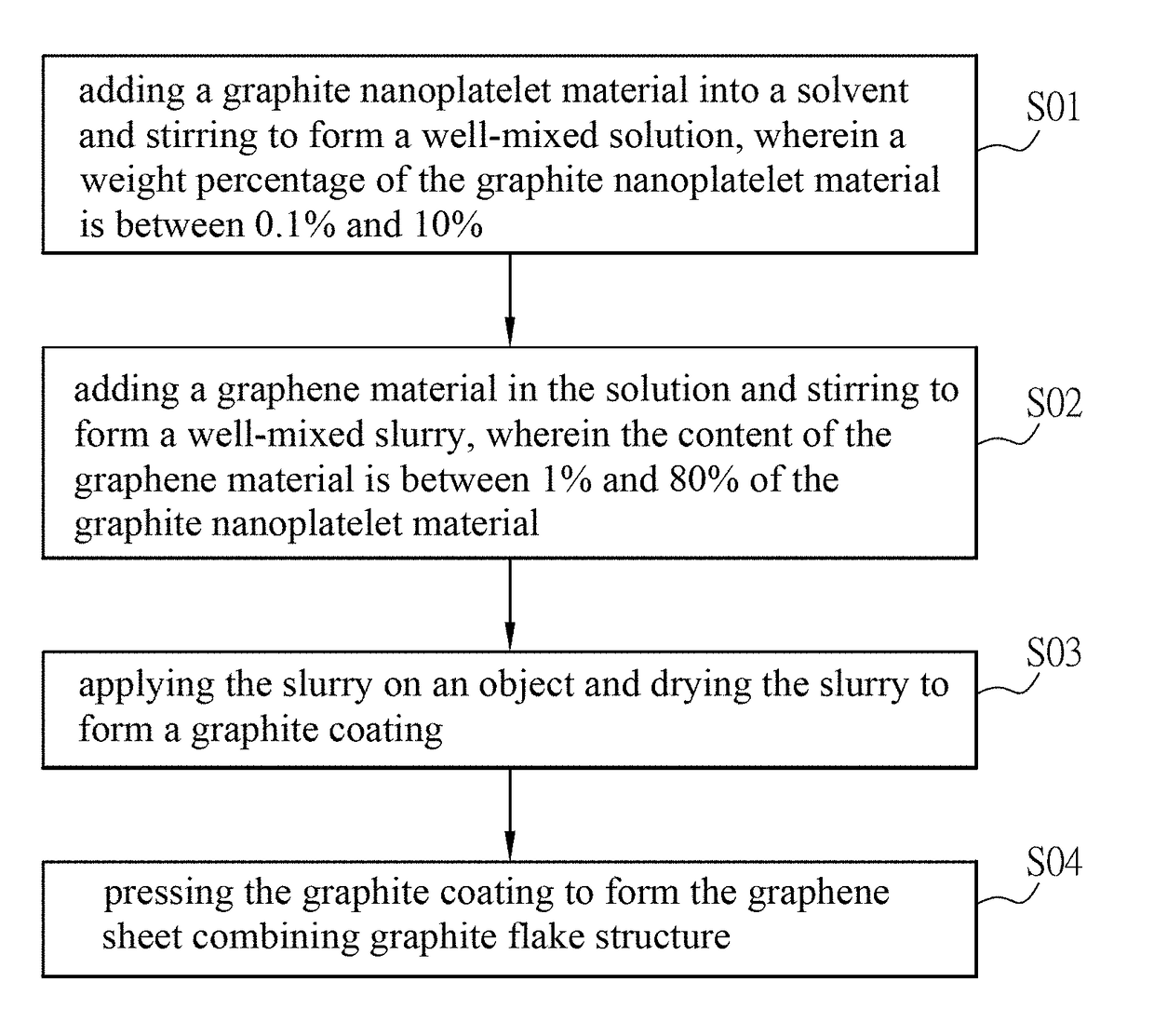

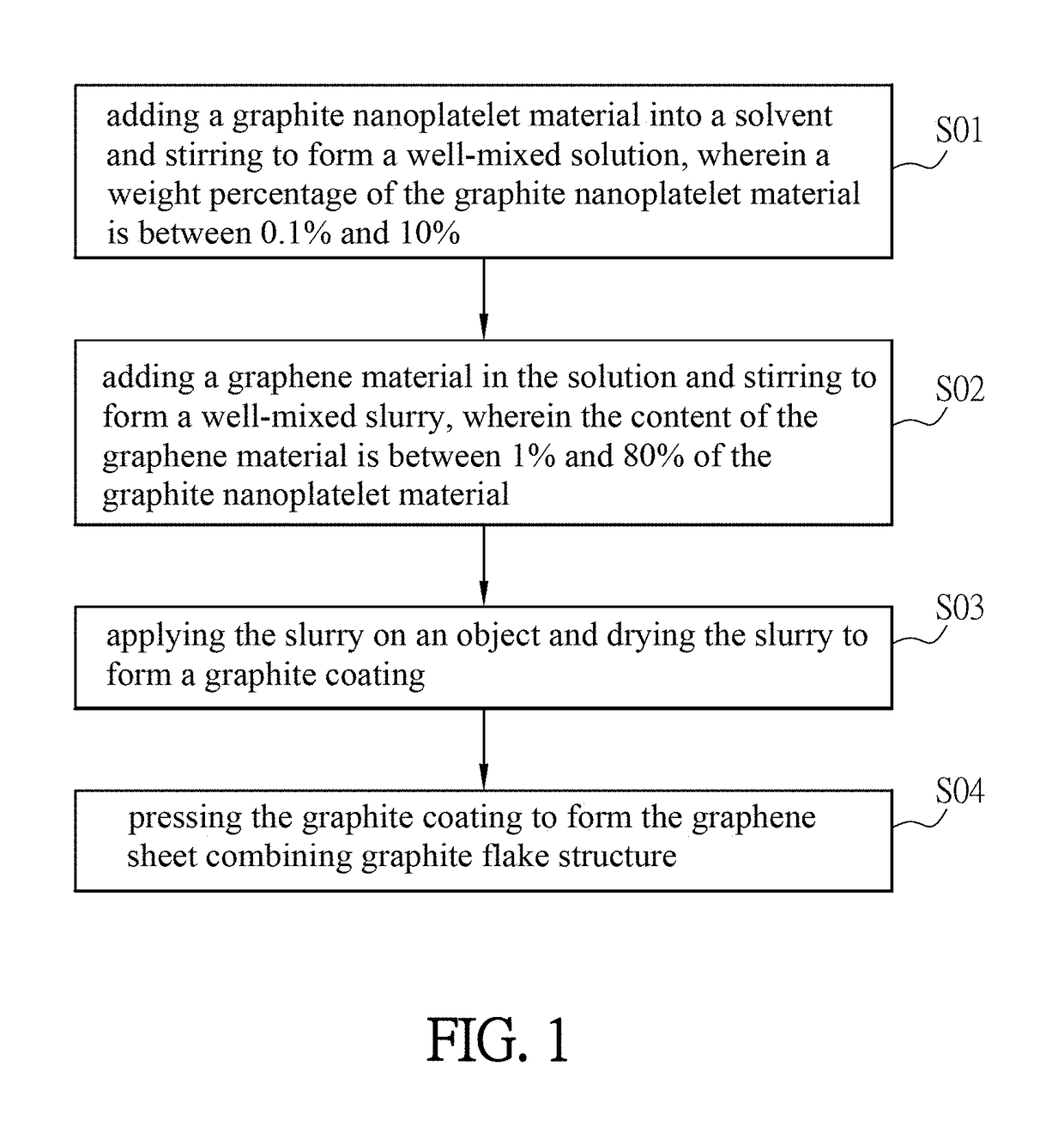

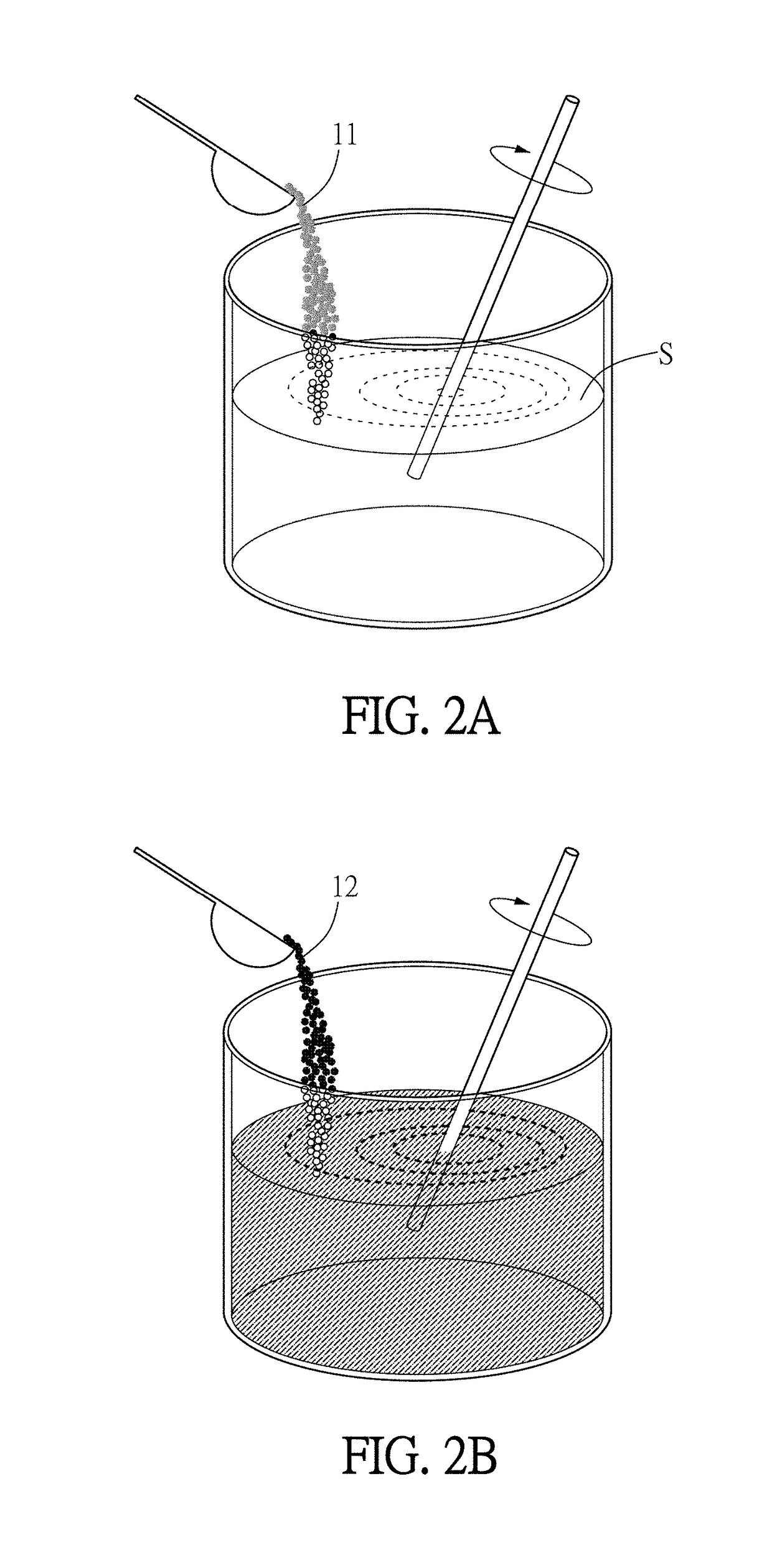

[0030]FIG. 1 is a flow chart of a manufacturing method of a graphene sheet combining graphite flake structure 1 according to an embodiment of the invention, and FIGS. 2A to 2G are schematic diagrams showing the manufacturing procedures of the graphene sheet combining graphite flake structure 1 according to the embodiment of the invention.

[0031]As shown in FIG. 1, the manufacturing method of a graphene sheet combining graphite flake structure 1 includes the following steps of: adding a graphite nanoplatelet material into a solvent and stirring to form a well-mixed solution, wherein a weight percentage of the graphite nanoplatelet material is between 0.1% and 10% (step S01); adding a graphene material in the solution and stirring to form a well-mixed slurry, wherein the content of the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com