Syringe including different materials

a technology of syringes and materials, applied in the field of syringes, can solve the problems of compromising the functionality of the syringe, damage to the syringe itself or in the leakage of the same, and disadvantageous to the connecting piece, so as to reduce the positional tolerance, reduce the cost of production, and increase the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

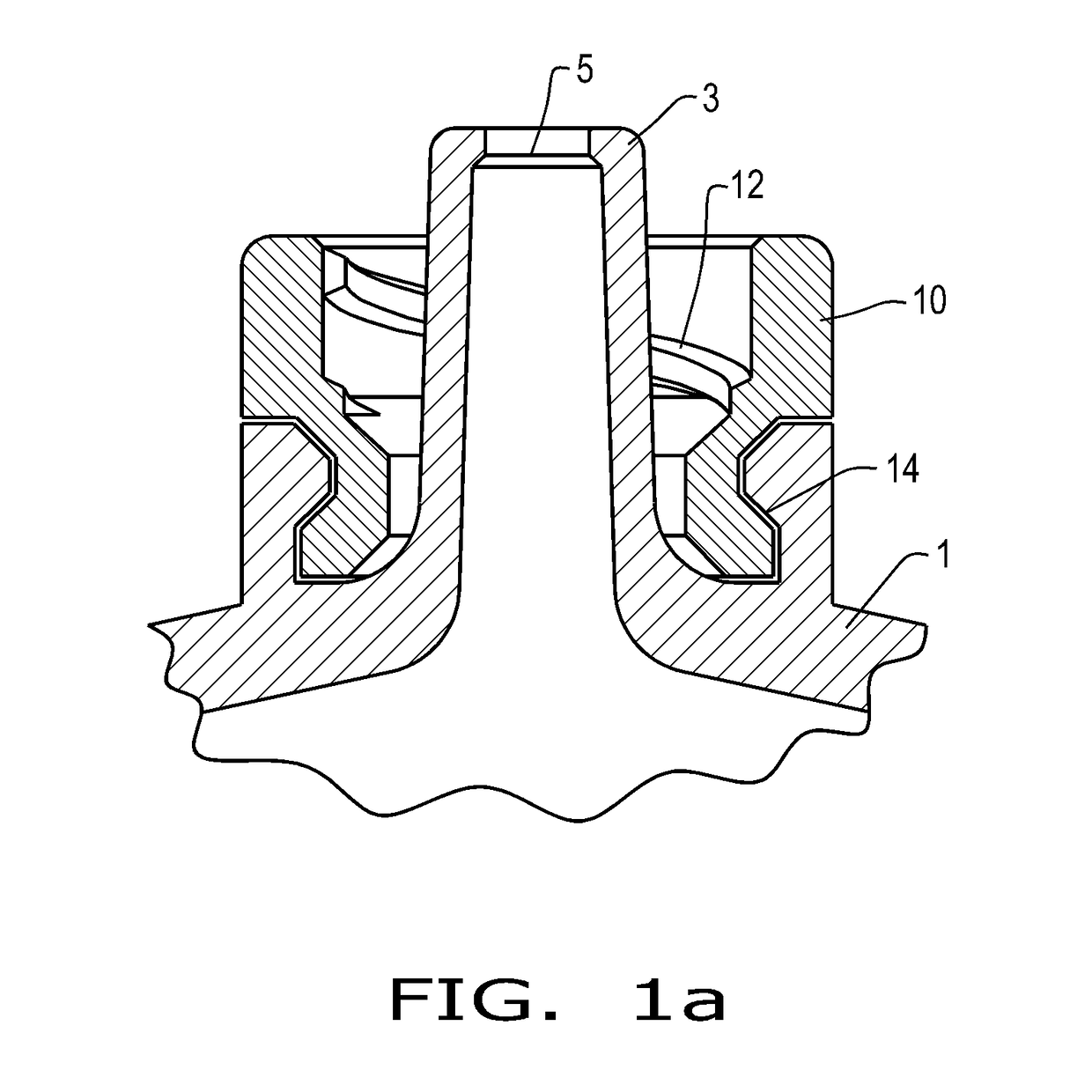

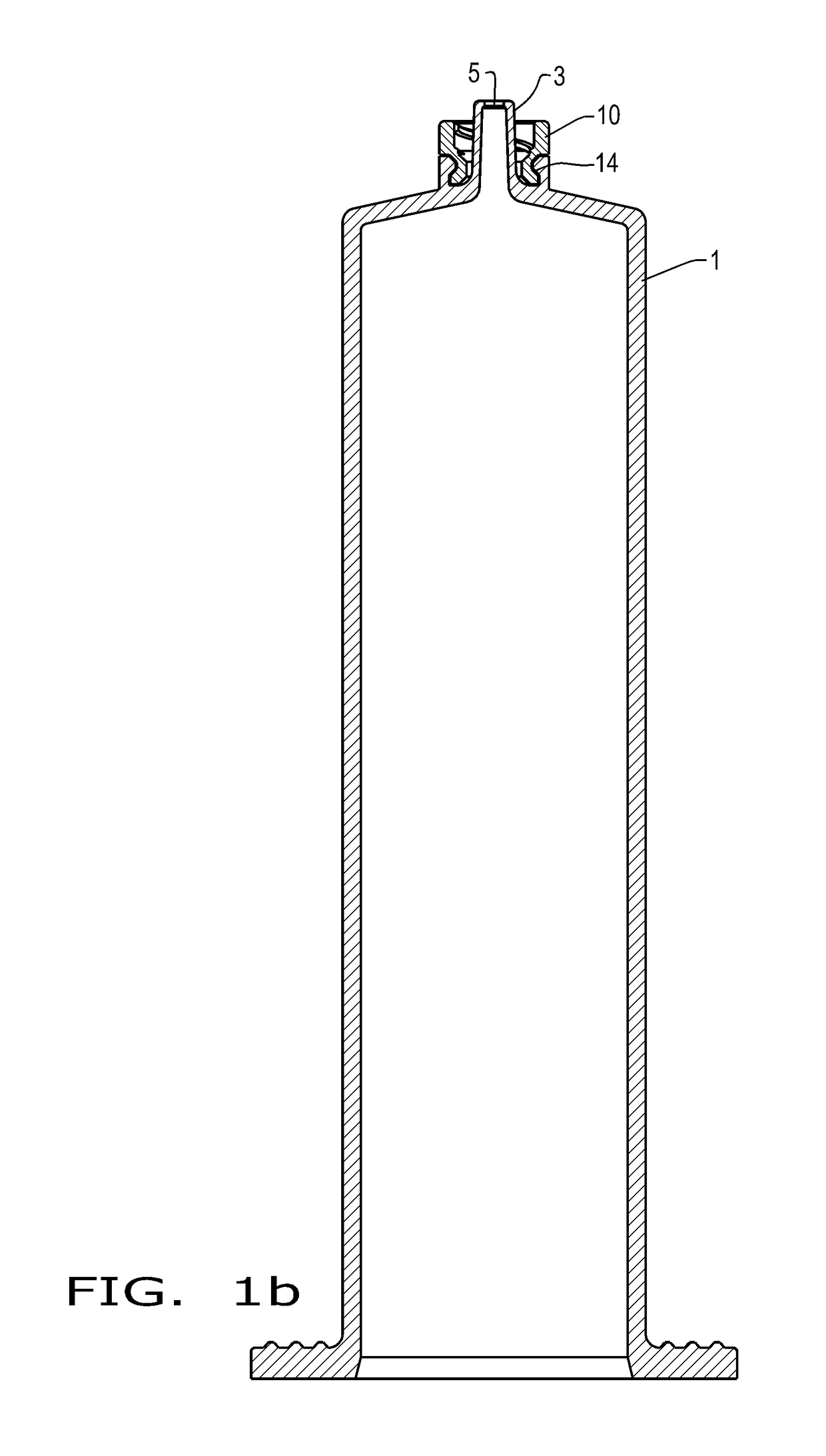

[0038]Referring now to the drawings, and more particularly to FIG. 1, there is shown a syringe body 1 which generally includes a syringe cone 3, with a distal opening 5. Of entire syringe body 1, only the upper part of the syringe in the region of syringe cone 3 is shown. Syringe body 1 preferably consists of a hard plastic, for example a cycloolefin-copolymer (COC) or cycloolefin-polymer (COP). A connector 10 for connectors or respectively attachment of syringes is arranged about syringe cone 3. Connection 10 in this example is an attachment with an inside thread 12, without being limited to same. Connection 10 in this example is an independent part vis-à-vis syringe body 3. In the illustrated embodiments according to FIG. 1, the syringe body as the first component and the connector as the second component are only mechanically connected with one another. For example, connection 10 is placed onto the syringe body and is locked in place in an undercut 14, in other words, the connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com