System for picture packaging and framing

a picture and packaging technology, applied in the field of picture packaging and framing systems, can solve the problems of frame bowing, difficult use, and frame bending, and achieve the effects of high functionality, accurate and simple, and efficient use of packing volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]The present invention in at least some embodiments is a picture packaging and framing system that allows mailing, transport or storage of a picture along with a frame that is partially assembled and simple to complete, that makes efficient usage of packing volume, and that does not waste packaging or storage materials.

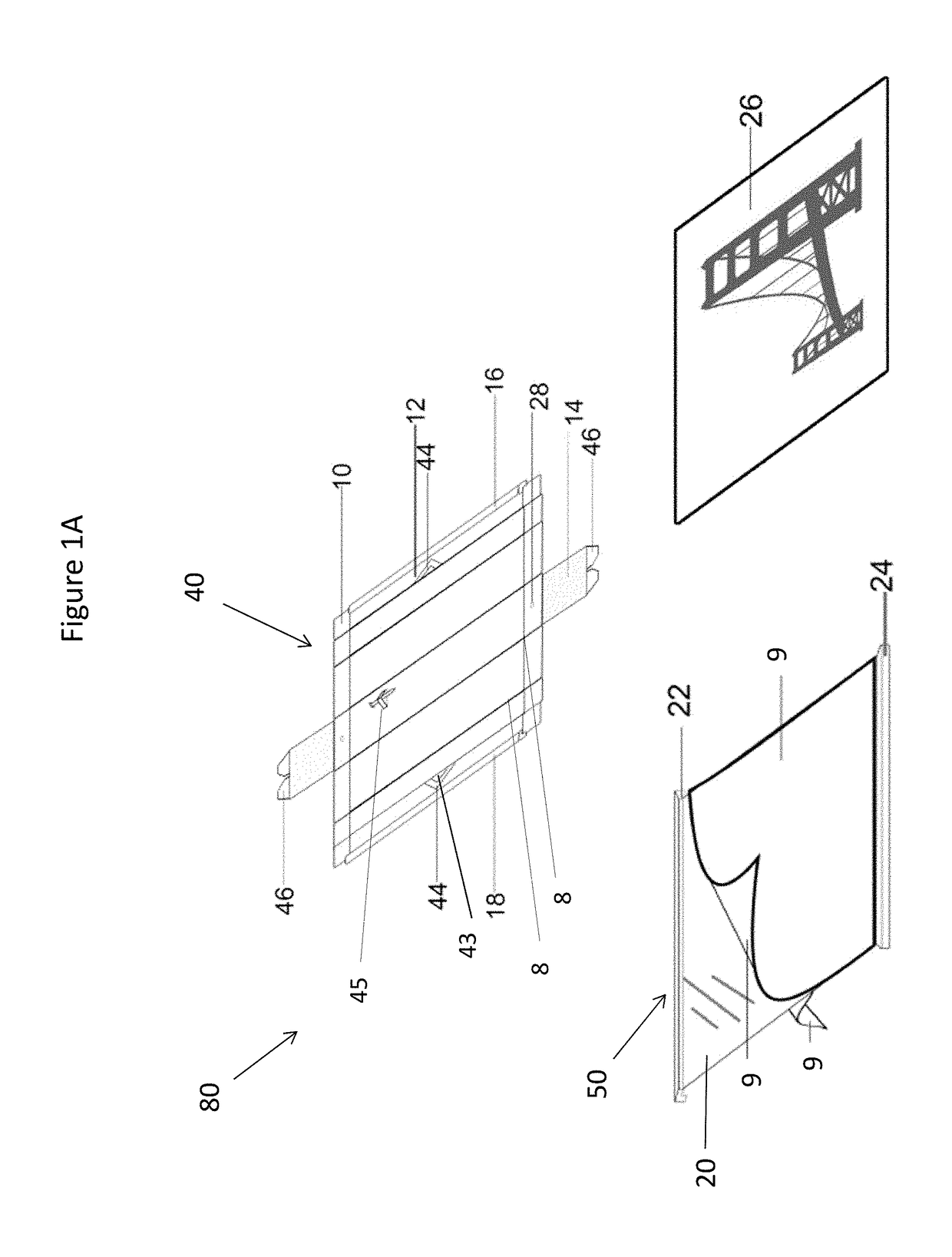

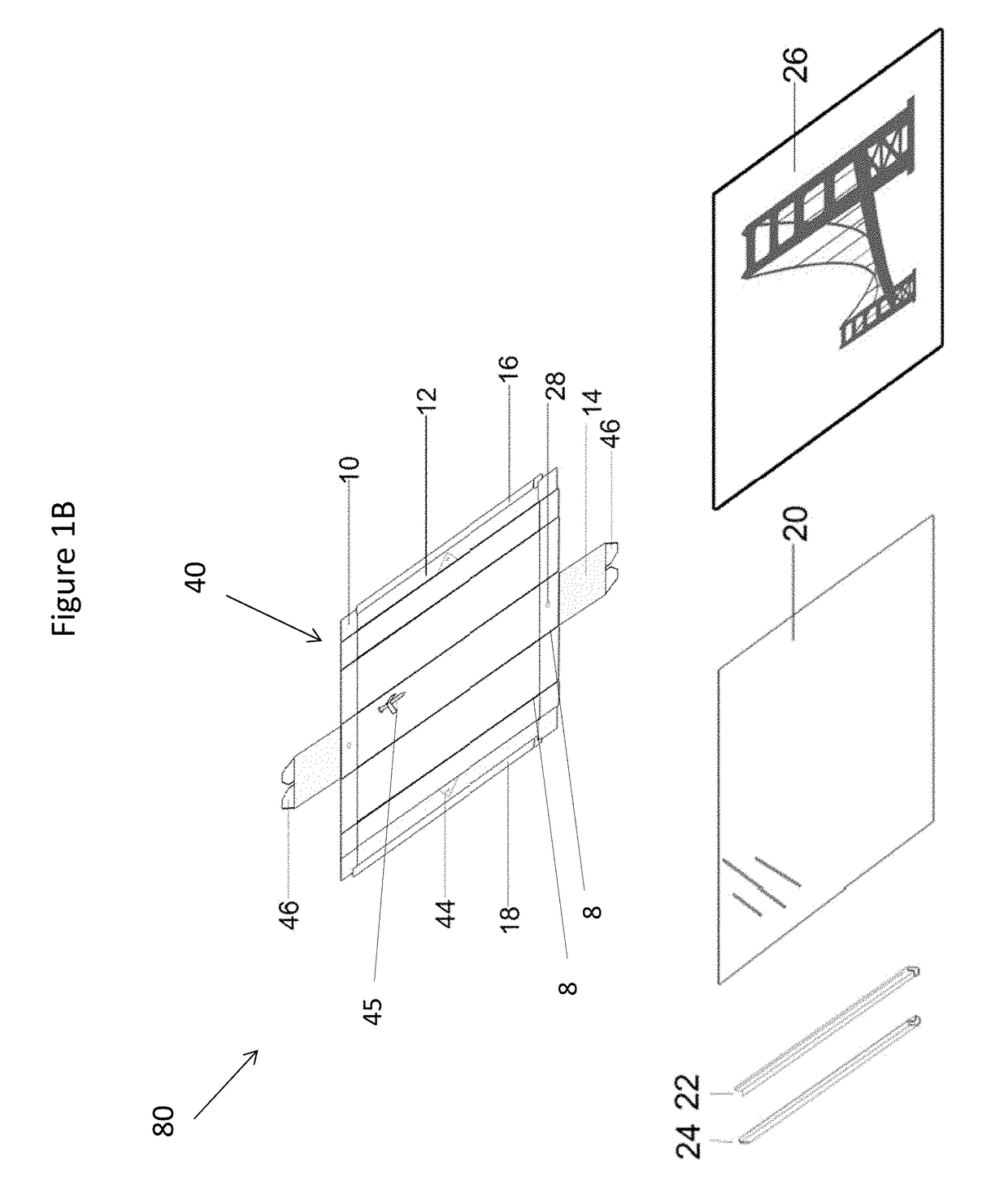

[0057]Reference is now made to FIGS. 1A-1U which are illustrative schematic drawings showing a picture packaging and framing system according to at least some embodiments of the present invention. As shown in FIG. 1A, picture packaging and framing system 80 comprises backing assembly 40, frame cover assembly 50, and picture 26. FIG. 1A shows the components of framing system 80 in an unassembled form. Backing assembly 40 and cover assembly 50 are adapted to fit picture 26 so that picture 26 can be framed in the frame form of system 80.

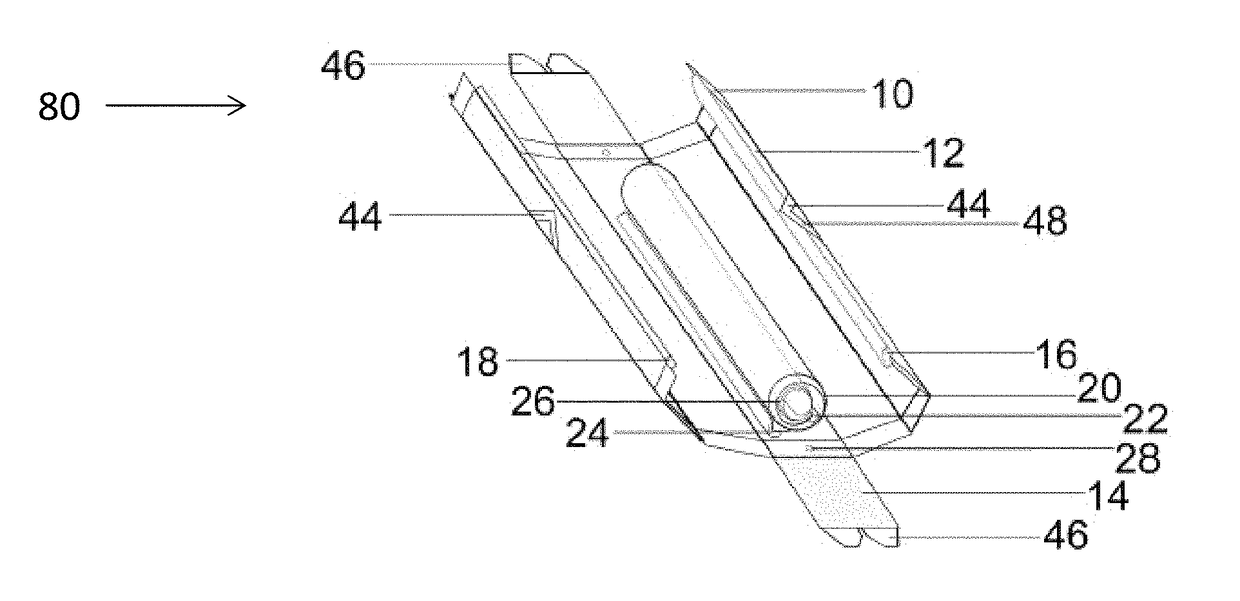

[0058]Backing assembly 40 comprises backing board 12 and backing frame members 16 and 18 which are fixedly attached to backing boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com