Downhole coal seam pulse detonation wave directional fracturing permeability-increasing method

a permeability-increasing and pulse detonation wave technology, applied in the direction of fluid removal, borehole/well accessories, mining structures, etc., can solve the problems of difficult gas extraction, complex process, and gas extraction effect, so as to improve the air permeability in the coal mass, improve the air permeability coefficient, and improve the effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Hereunder the present invention will be detailed in an embodiment with reference to the accompanying drawings.

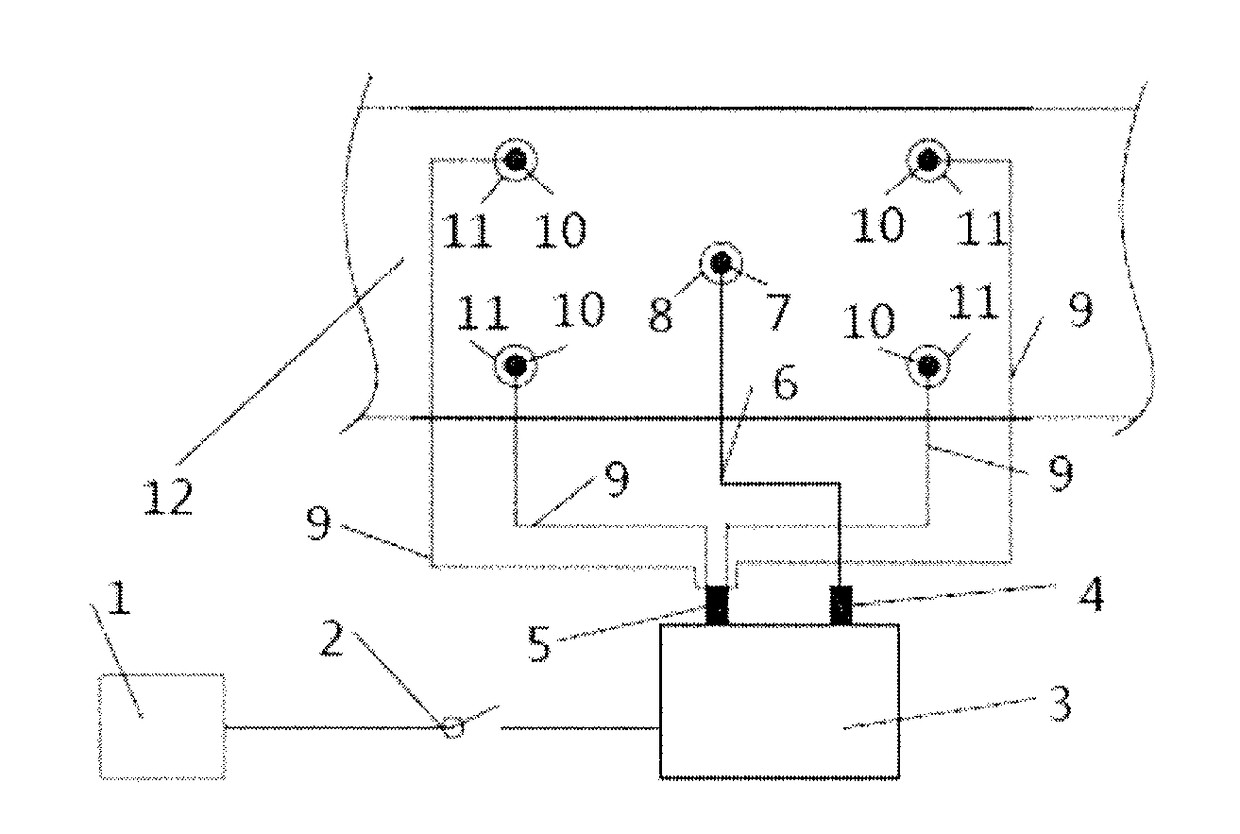

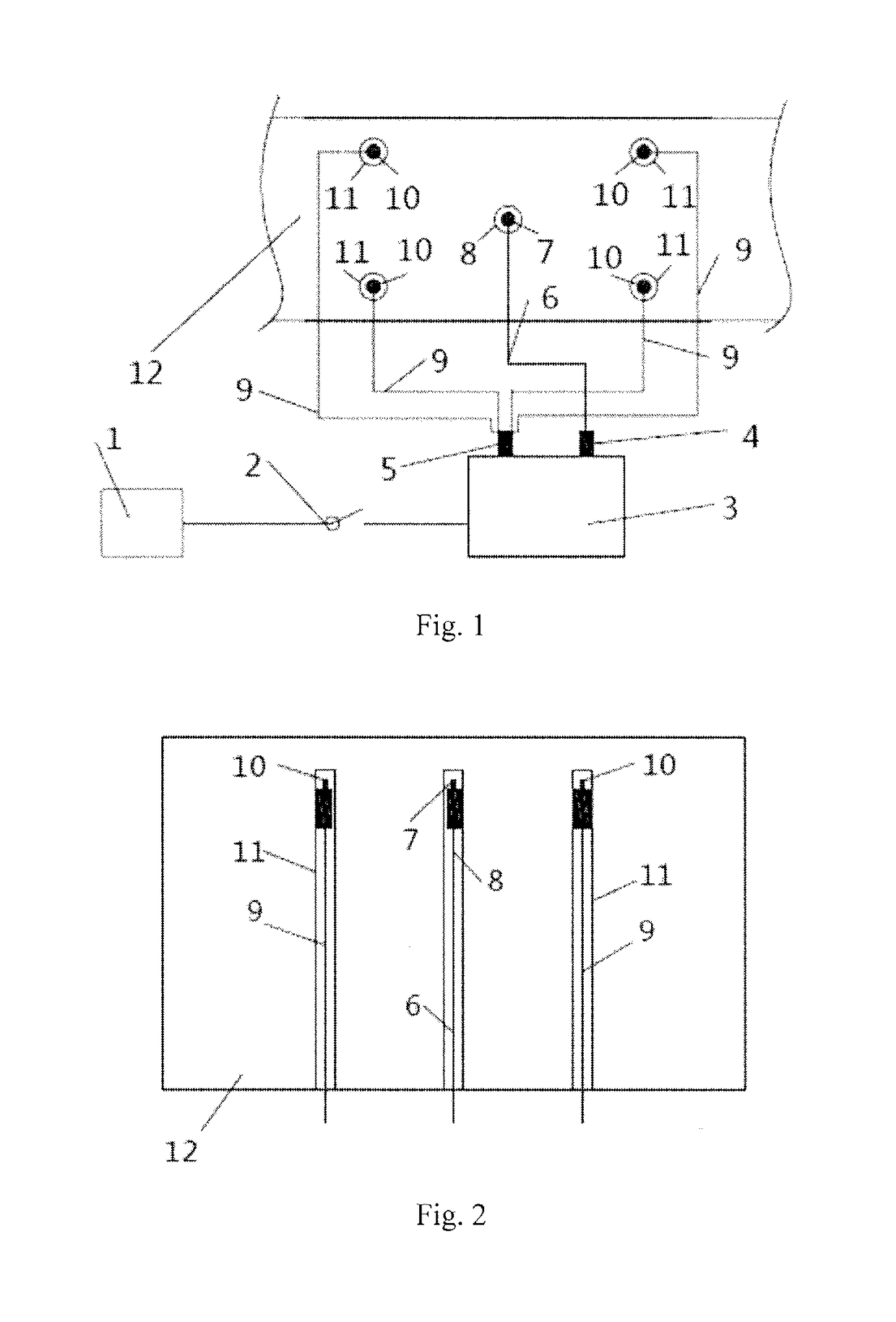

[0019]The method for permeability improvement for a downhole coal seam by directional fracturing with pulsed detonation waves provided in the present invention employs an explosion-proof high-voltage electrical pulse generator 3, and comprises the following steps:[0020](1) drilling a pulsed detonation borehole 8 from the wall of a roadway to a coal seam 12 according to FIG. 1, and then drilling four pulsed detonation guide boreholes 11 around the pulsed detonation borehole 8, the four pulsed detonation guide boreholes 11 are at the same distance to the pulsed detonation borehole 8, and are parallel to each other; the distance from the pulsed detonation borehole 8 to each of the four pulsed detonation guide boreholes 11 is 4-6 m;[0021](2) connecting the input side of the explosion-proof high-voltage electrical pulse generator 3 to an explosion-proof power cabinet 1 via ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com