Freeze-thaw durable geopolymer compositions and methods for making same

a geopolymer composition and freeze-thaw technology, applied in the direction of climate sustainability, solid waste management, construction, etc., can solve the problems of expansion and cracking, scaling, concrete collapse, etc., and achieve freeze-thaw durability behavior, good dimensional stability, and sufficient workable time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

aw Durability Performance of Geopolymer Compositions of the Invention

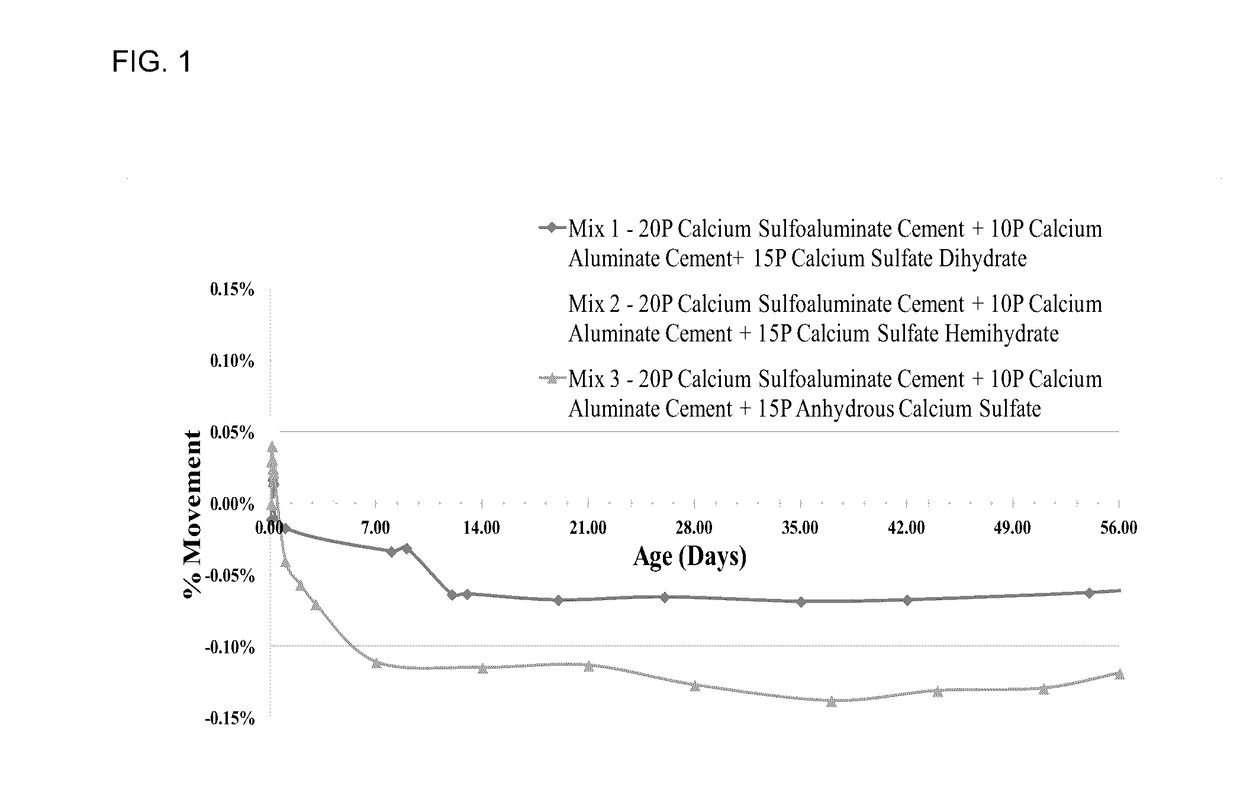

[0340]TABLE 2.1 shows the raw material composition of the mixture composition investigated. This example investigated freeze-thaw durability performance of three different compositions employing three different types of calcium sulfates. Mix 1 employed calcium sulfate dihydrate (USG TERRA ALBA), Mix 2 employed calcium sulfate hemihydrate (USG HYDROCAL C-BASE), and Mix 3 employed anhydrous calcium sulfate (anhydrite—USG SNOW WHITE FILLER). The material was mixed using a high shear mixer—PERLS hand held ME 140 mixer operated manually at a RPM of 490. The mixing was performed for 4 minutes. The sand used in this example was Sand A Unimin GRANUSIL 5030.

TABLE 2.1Compositions investigated in Example 2Raw MaterialMix 1Mix 2Mix 3Fly Ash Class C (grams)103451034510345Calcium Sulfoaluminate Cement206920692069(grams)Calcium Aluminate Cement103410341034(grams)Calcium Sulfate Dihydrate1552——(grams)Calcium Sulfate Hemihydrate—15...

example 3

aw Durability Performance—Influence of Different Levels of Calcium Aluminate Cement with Calcium Sulfate Hemihydrate

[0352]TABLE 3.1 shows the raw material composition of the inventive mixture compositions investigated in this example.

[0353]The high shear mixer used in this example was PERLS hand held ME 140 mixer operated manually at a RPM of 490. The mixing was performed for 4 minutes.

TABLE 3.1Compositions investigated in Example 3Raw MaterialMix 1Mix 2Fly Ash Class C (grams)103459836Calcium Sulfoaluminate Cement (grams)20691967Calcium Aluminate Cement (grams)10341475Calcium Sulfate Hemihydrate (grams)15521721Total Cementitious Materials (grams)1500015000Sand A (grams)1725017250Potassium Citrate (grams)300300Superplasticizer (grams)7575Rheology Modifier (grams)1.51.5Defoamer (grams)3030Lithium Carbonate (grams)7575Polymer (grams)750750Water (grams)33003300Water / Cementitious Materials Wt. Ratio0.22:10.22:1Sand A / Cementitious Materials Wt. Ratio1.15:11.15:1Calcium sulfoaluminate ceme...

example 4

aw Durability Performance—Influence of Water to Cementitious Materials Ratio

[0360]This example investigated the influence of water-cementitious materials ratio on the freeze-thaw durability performance of the geopolymeric formulations investigated. TABLE 4.1 shows the raw material composition of the mixture compositions investigated. The high shear mixer used in this example was PERLS hand held ME 140 mixer operated manually at a RPM of 490. The mixing was performed for 4 minutes.

TABLE 4.1Compositions investigated in Example 4Raw MaterialMix 1Mix 2Mix 3Fly Ash Class C (grams)103451034510345Calcium Sulfoaluminate Cement (grams)206920692069Calcium Aluminate Cement (grams)103410341034Calcium Sulfate Hemihydrate (grams)776776776Anhydrous Calcium Sulfate (grams)776776776Total Cementitious Materials (grams)150001500015000Sand A (grams)172501725017250Potassium Citrate (grams)300300300Superplasticizer (grams)757575Rheology Modifier (grams)1.51.51.5Defoamer (grams)303030Lithium Carbonate (gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight ratio | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com