Conveyors for box making machines

a box making machine and conveying technology, applied in the field of conveying machines, can solve the problems of affecting image, affecting image, smudging, distorted, etc., and is not acceptable in the printing industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

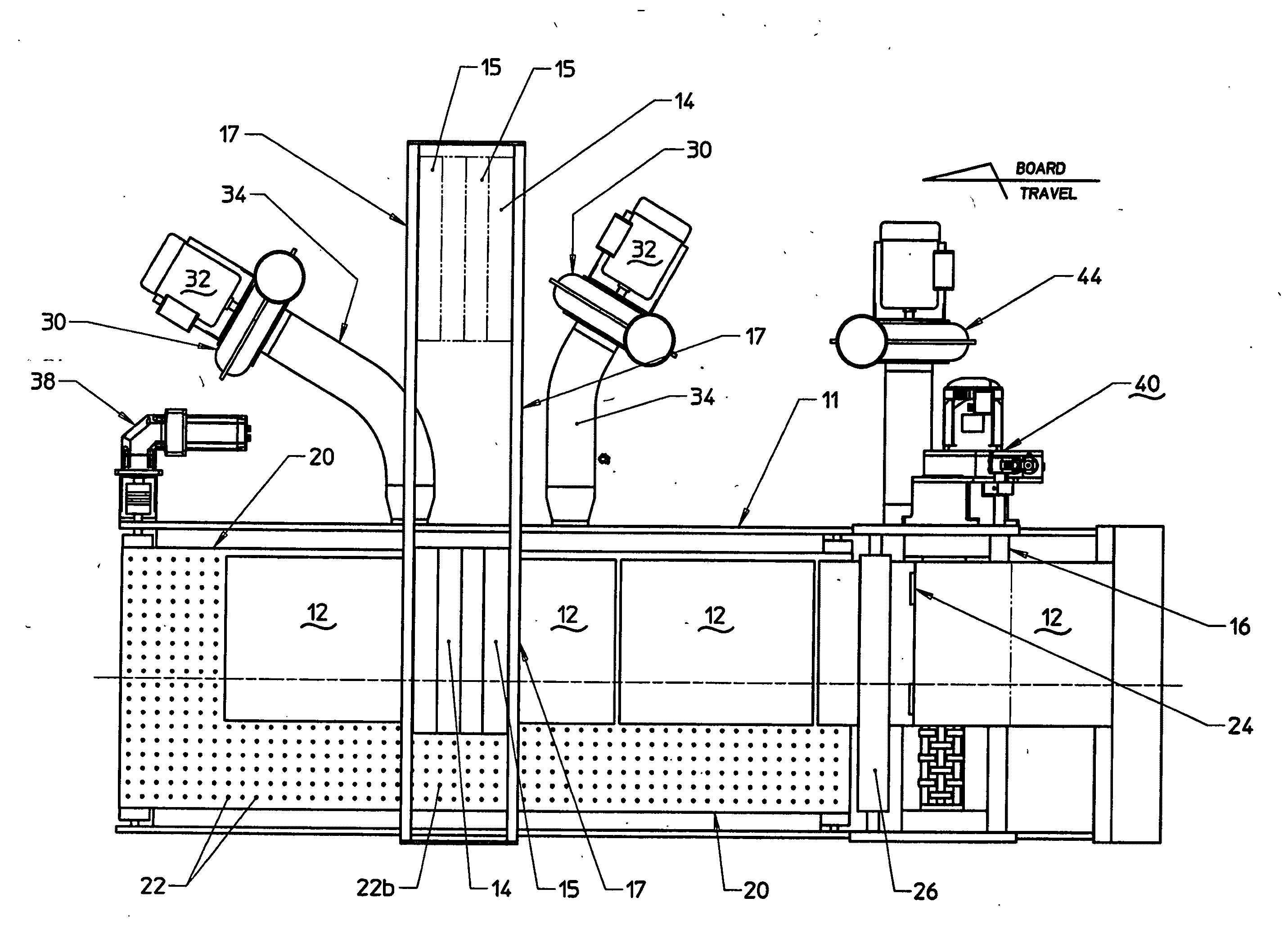

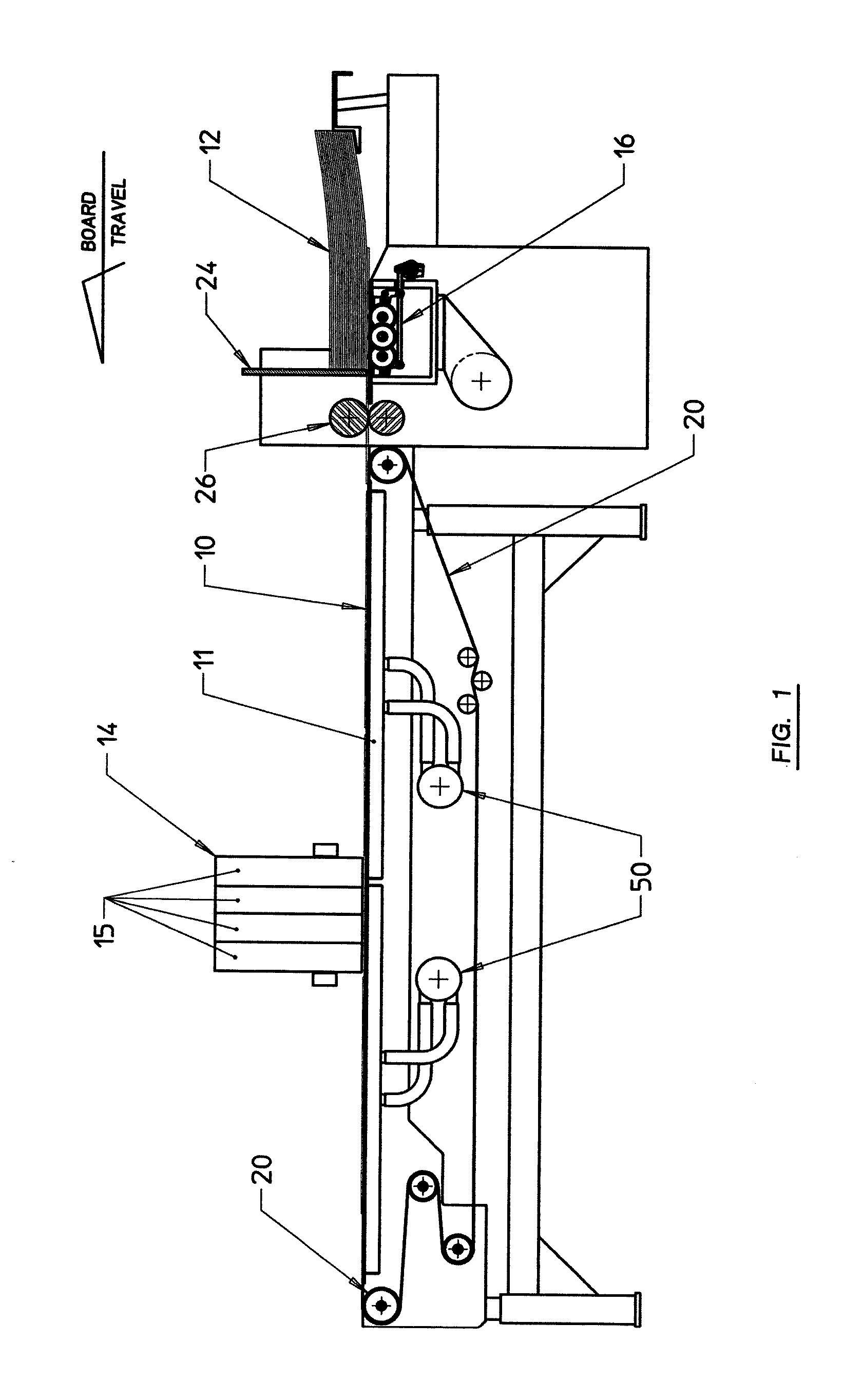

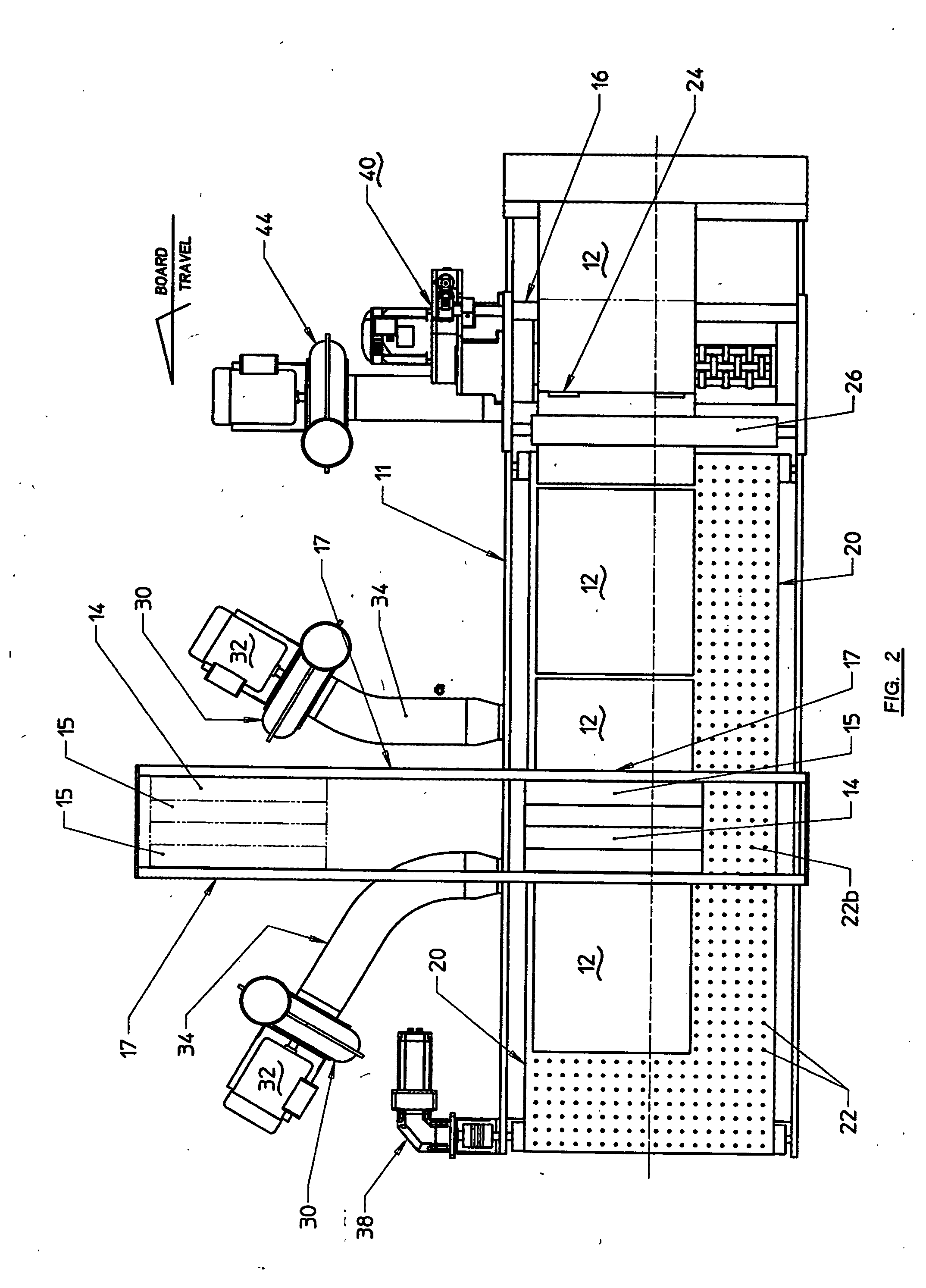

[0026]Referring to the drawings in detail and initially to FIGS. 1-5, there is shown for illustrative purposes only, one preferred embodiment of the present invention including a belt conveyor 10 for sequentially feeding sheets such as corrugated boards 12 one behind the other in horizontal planes along a horizontal path to a digital printer 14 for printing an image on the top surface of the boards 12 when they arrive below the printer 14. Also shown is a feeder 16 for feeding the boards 12 one by one in a predetermined timed fashion to conveyor 10 from a stack of boards. Feeder 16 is a timed feeder such as described in U.S. Pat. No. 7,635,124 B2 to Sardella whose disclosure is hereby incorporated by reference into the present application as part hereof. For a particular job, feeder 16 delivers a board 12 to conveyor 10 at a predetermined interval of time so that the boards 12 are transported to the printer 14 with the same predetermined space or gap 18 between successive boards, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com