Aqueous solution and method for use thereof

a technology of hydrochloric acid and solution, applied in the field of high-concentration hydrochloric acid (hcl) solution with urea, can solve the problems of reducing the properties of previously available solutions,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

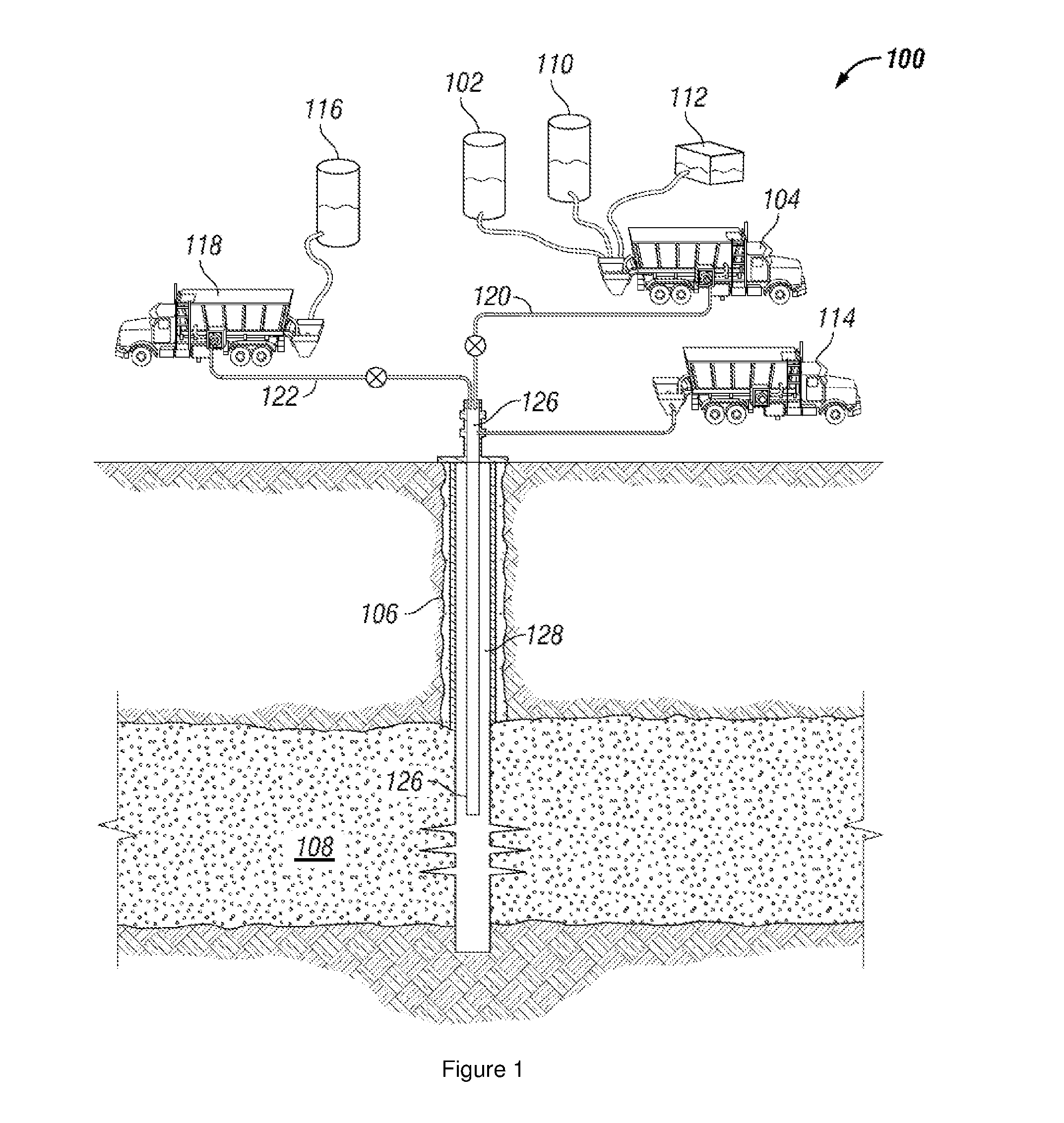

Image

Examples

example 1

[0038]A 15 wt % solution of HCl was prepared by diluting 37 wt % HCl with urea (FA1) and water. Corrosion tests were performed during which the HCl solution was tested alone, with FA1, and with FA1 and FA2. The solutions were heated to 93° C. (200° F.) during which a steel coupon was immersed in each solution for four hours. The results are presented in Table 1.

TABLE 1Corrosion test results: N80 steel; 93° C.; 4 hAcid FormulationCorrosion ResultsFA1 / HClCorrosion(molarInhibitorPittingRateFluidratio)FA2aidIndex(lb / ft2)15% HClN / AN / AN / A30.699015% HCl + Urea1N / AN / A30.463515% HCl + Urea10.1%N / A10.0068

[0039]Compared to the control solution of 15% HCl, the presence of FA1 alone at an FA1 / HCl molar ratio equal to 1 reduced the corrosion rate by more than 33%; however, the corrosion rate was significantly higher than 0.05 lb / ft2. Satisfactory corrosion inhibition was observed by adding a small amount of FA2.

example 2

[0040]A 15 wt % solution of HCl was prepared by diluting 37 wt % HCl with urea (FA1) and water. Corrosion tests were performed during which the HCl solution was tested alone, and with a mixture of FA2 and inhibitor aid. The solutions were heated to 135° C. (275° F.) during which a steel coupon was immersed in each solution for four hours. The results are presented in Table 2.

TABLE 2Corrosion test results: N80 steel; 135° C.; 4 hAcid FormulationCorrosion ResultsFA1 / HClCorrosion(molarInhibitorPittingRateFluidratio)FA2aidIndex(lb / ft2)15% HClN / AN / AN / A40.648415% HCl + Urea0.4N / AN / A40.106615% HCl + Urea0.40.1%0.4%00.0091

[0041]The presence of FA1 at a molar ratio FA1 / HCl=0.4 reduced the corrosion rate more than six fold compared to a solution of 15% HCl alone. However, the corrosion rate remained above 0.05 lb / ft2. Satisfactory results were obtained when both FA2 and inhibitor aid were present.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar ratio | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com