Gas fireplace and flow guide member of the same

a flow guide and gas fireplace technology, which is applied in the direction of gaseous heating fuel, stoves or ranges, combustion types, etc., can solve the problems of eddies leaving the surface, no longer attaching fluid to the surface of the object, etc., and achieves a stable flow, enhance the performance of the gas fireplace, and reduce the temperature at the glass cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

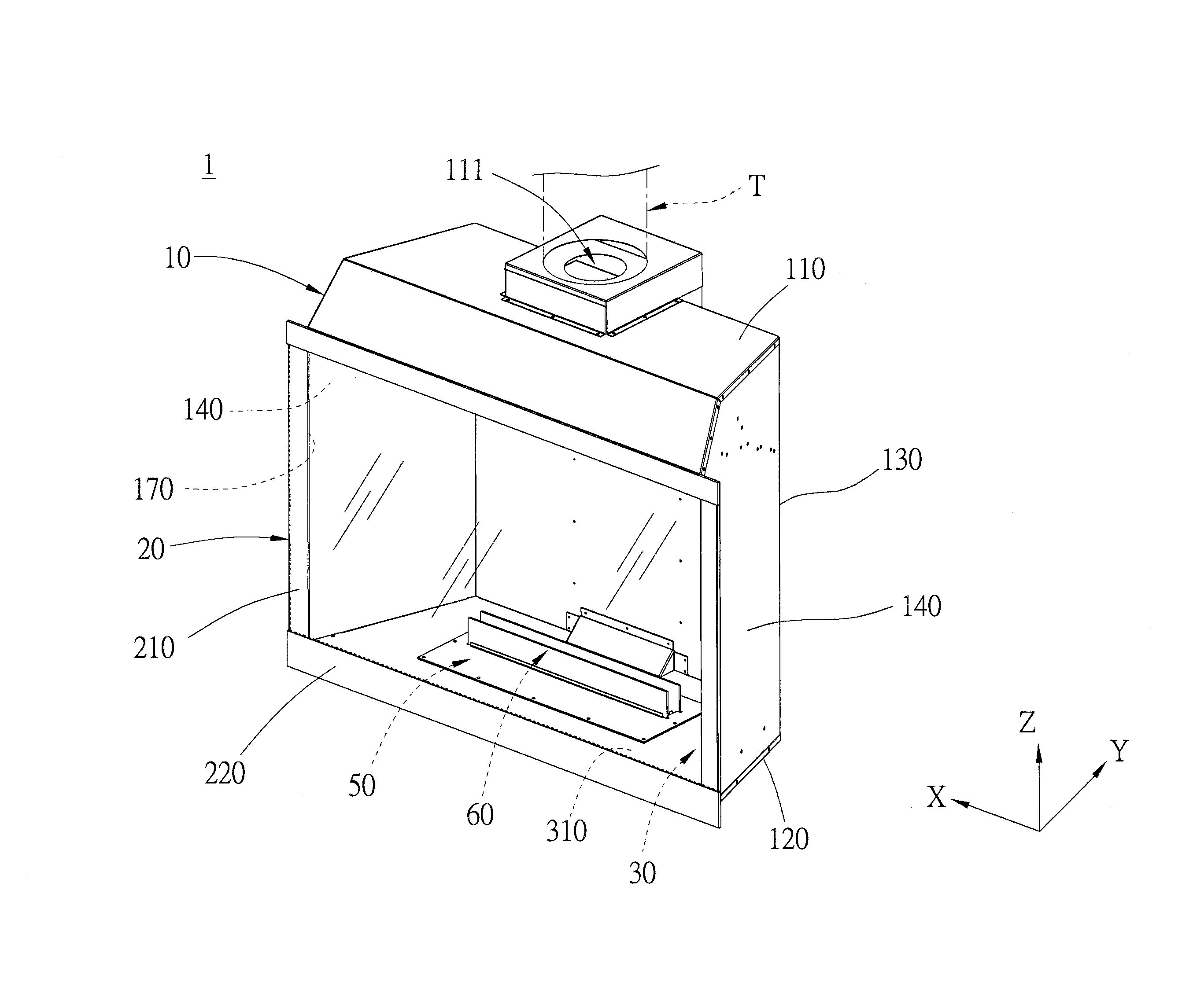

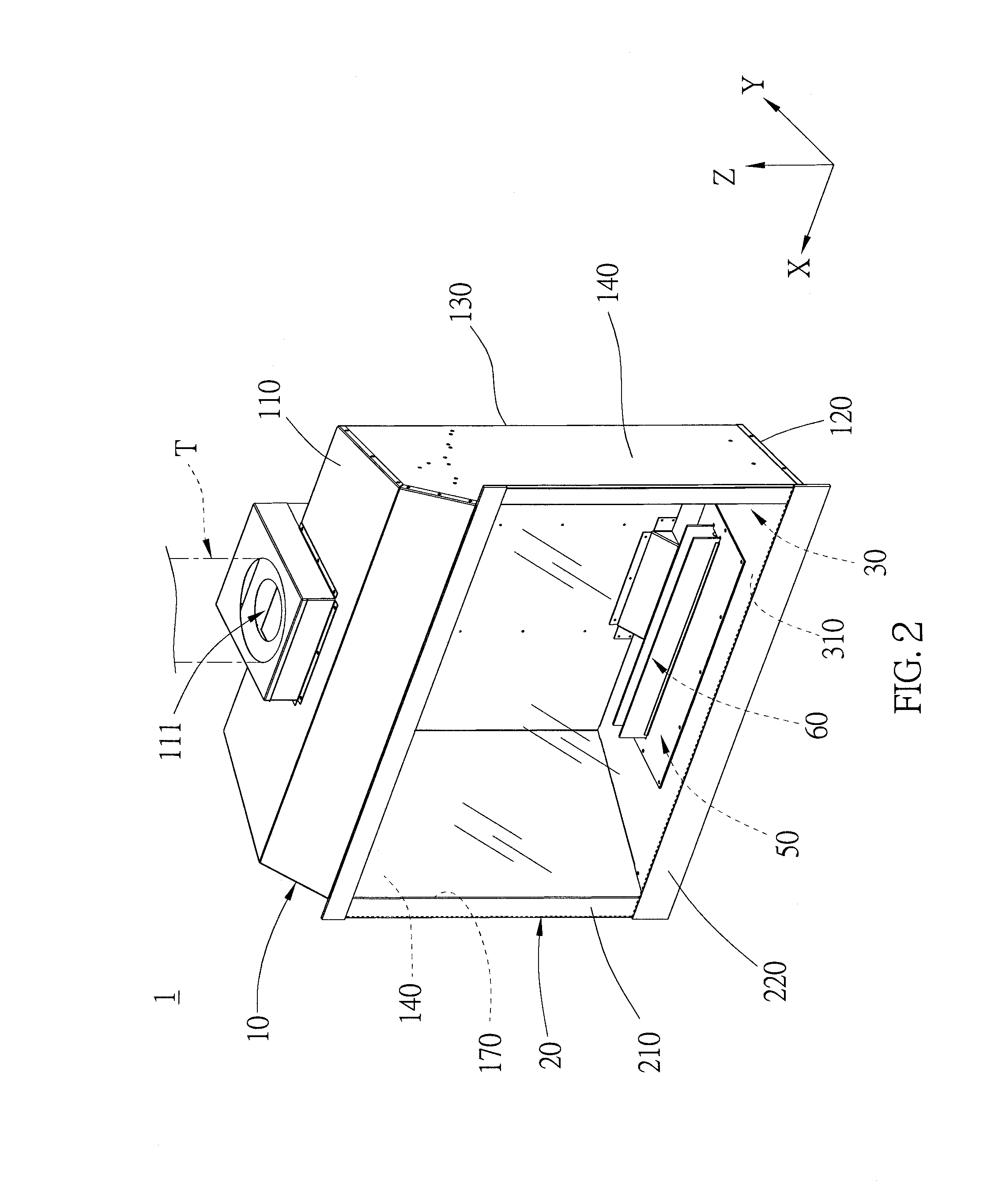

[0028]As shown in FIG. 2 to FIG. 5, a gas fireplace 1 of an embodiment of the present invention includes a firebox 10, a translucent cover 20, and a separate assembly 30. To make the following explanation more understandable, the firebox 10 is defined to have a first axial direction X, a second axial direction Y, and third axial direction Z in a three-dimensional coordinate system, wherein the first axial direction X and the second axial direction Y are different directions on a horizontal plane with an included angle formed therebetween, while the third axial direction Z points upward in a vertical direction. In the third axial direction Z, the firebox 10 has a top portion 110 and a bottom portion 120 opposite to the top portion 501, wherein an exhaust port 111a is provided on the top portion 110, and an intake port 121 is provided either on the bottom portion 120 or another location on the firebox 10 near the bottom portion 120. Forward directions of the intake port 121 and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com