Sandwich Construction Fin Mounting

a technology of construction fins and fin plugs, which is applied in the field of watercraft, can solve the problems of insufficient foam of the core, insufficient support of the fin plug in resisting torsional loads, and insufficient laminate contact surface of the fin plug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

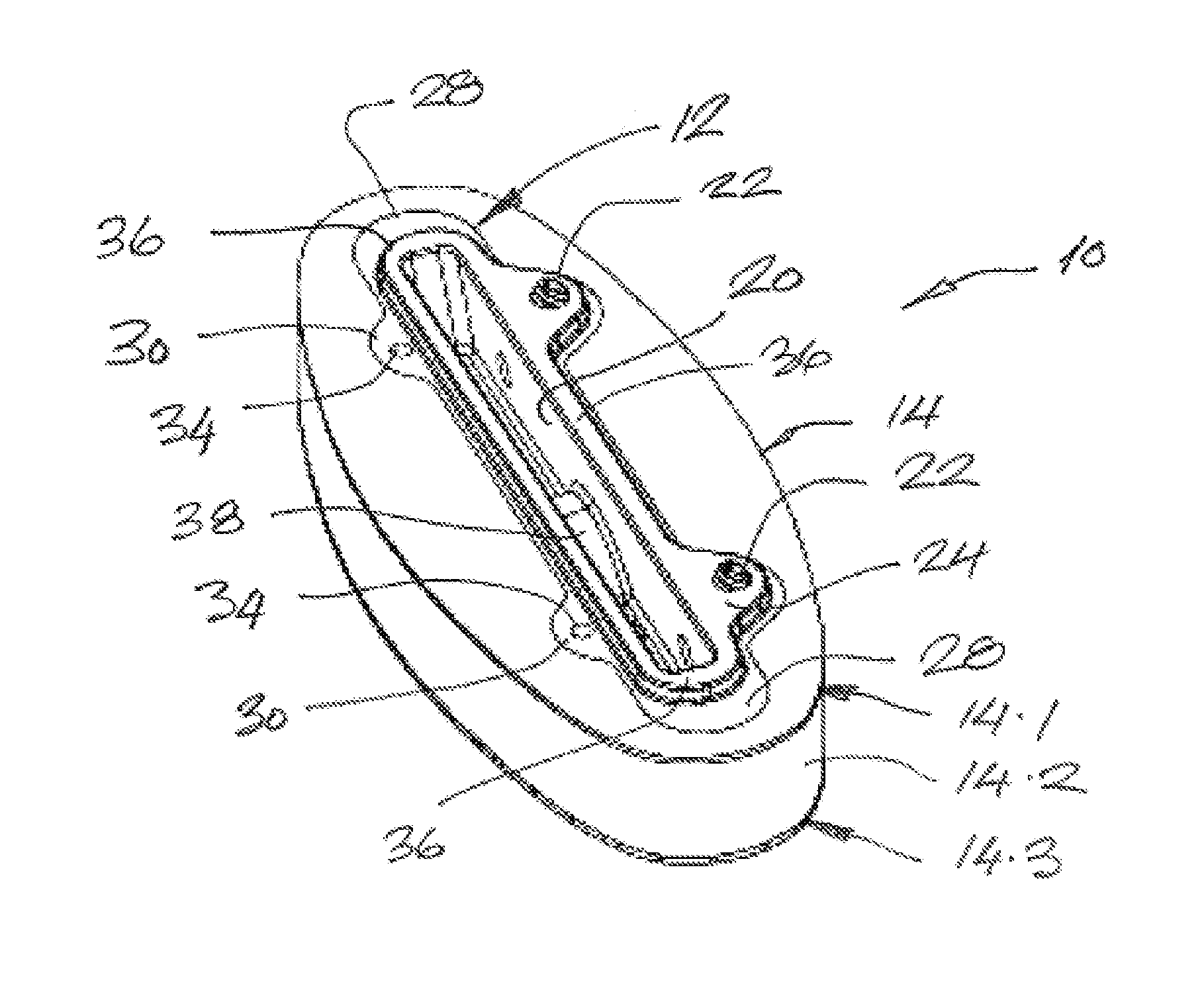

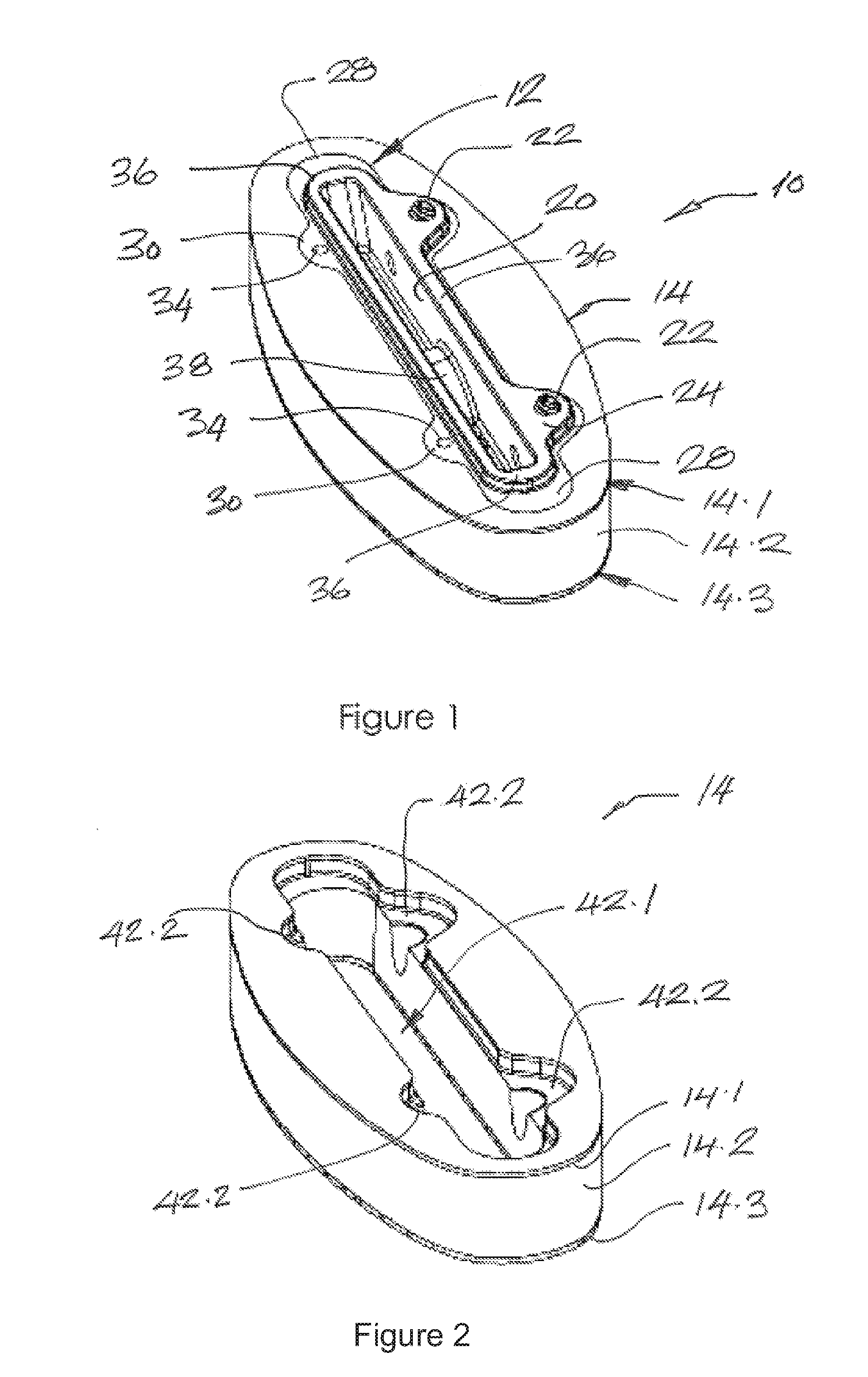

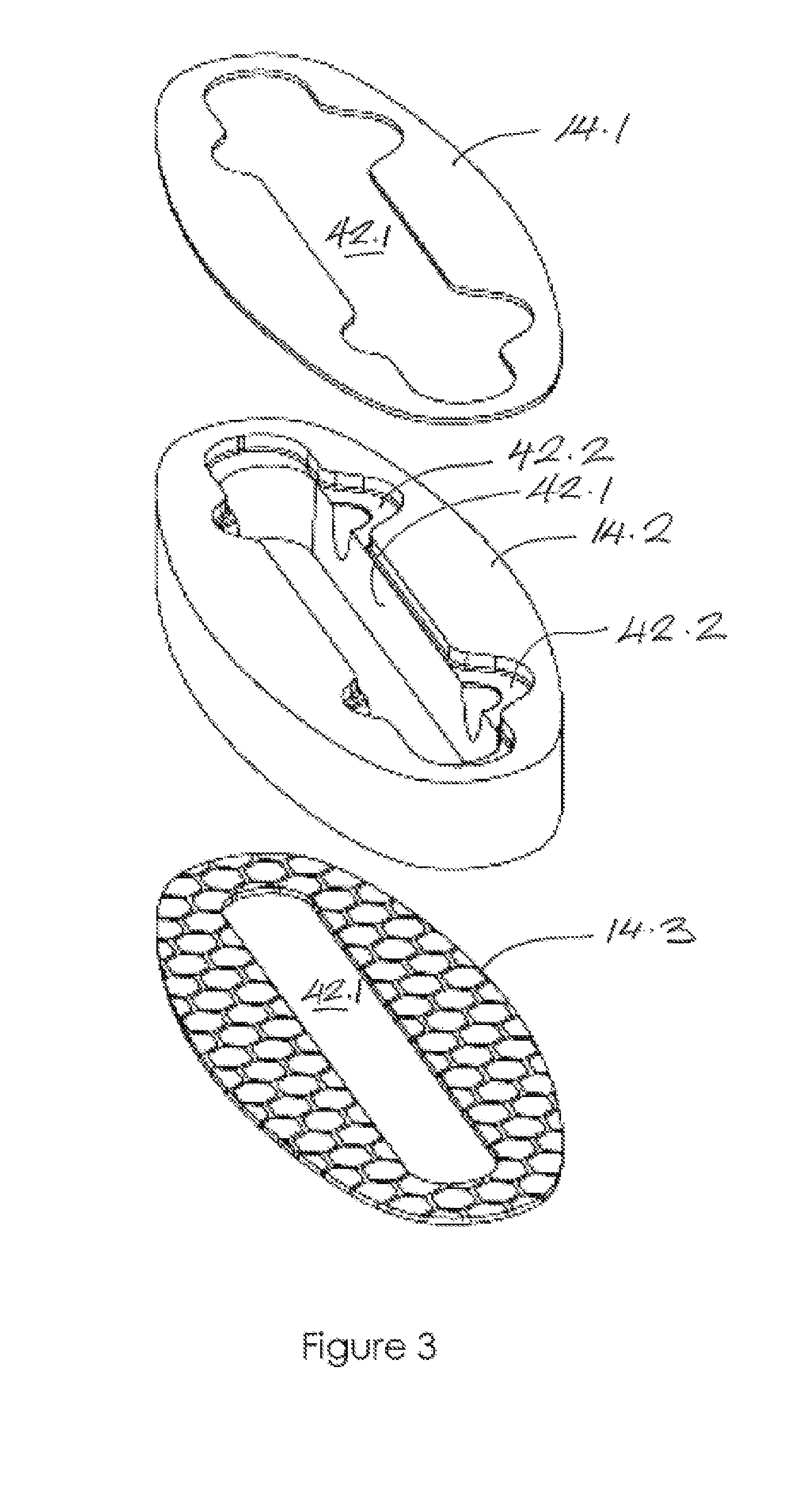

[0049]Two embodiments of the invention are illustrated in the drawings, the first embodiment being illustrated in FIGS. 1 to 5 and the second embodiment being illustrated in FIGS. 7 to 17, with like elements of the second embodiment being numbered with like numbers except that the first embodiment elements are numbered from 10 onwards and to the second embodiment elements are numbered from 110 onwards.

[0050]The fin plug assemblies illustrated in the drawings are intended for use in surfboards and, in essence, comprise a fin plug 12, 112 which is mounted within a mounting insert 14, 114. The fin plug 12, 112 is used to mount removable surfboard fins to the underside or water-facing surface of the surfboard (not shown). The mounting insert 14, 14 has a laminar or sandwich construction in which the water- and inwardly facing surfaces have laminar sheets or plates 14.1, 14.3; 114.1, 114.3 respectively laminated to a core 14.2; 114.2.

[0051]Referring first to FIGS. 1 to 6, the fin plug as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com