Method for operating a combined cycle power plant

a combined cycle and power plant technology, applied in the direction of machines/engines, mechanical equipment, light and heating equipment, etc., can solve the problems of increasing the pressure on the conventional power plant, so as to reduce the pressure, reduce the service life, and reduce the pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

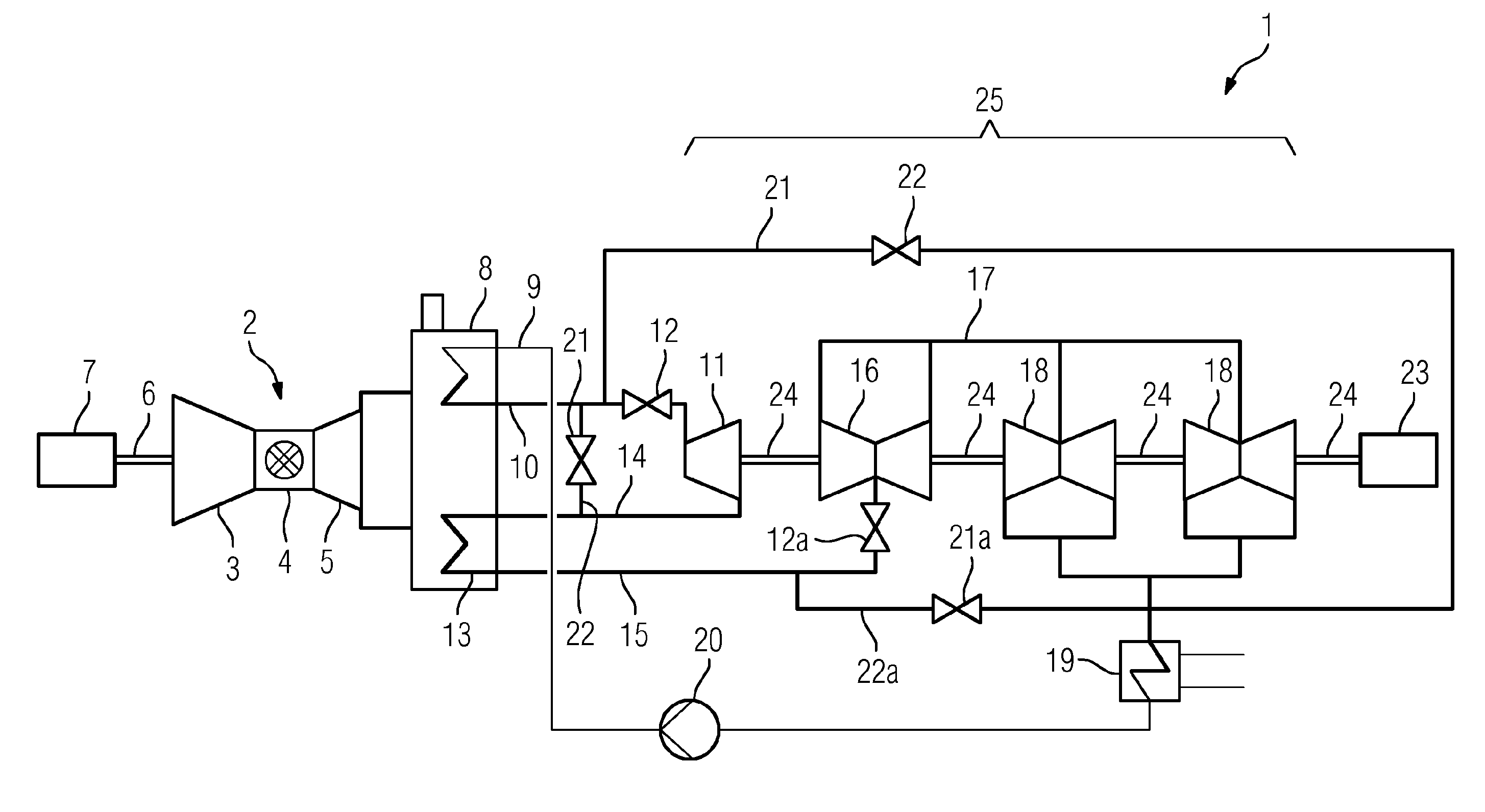

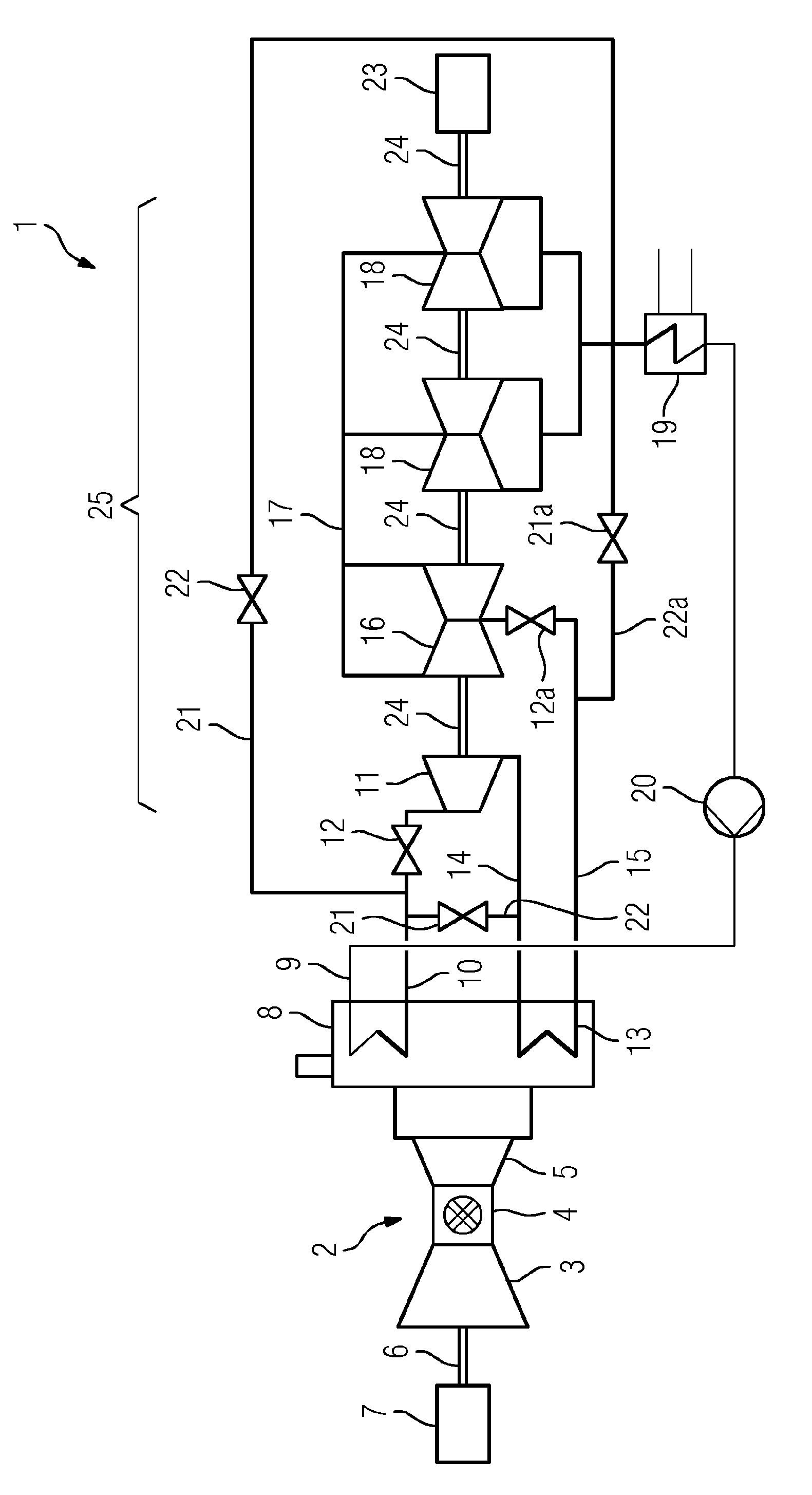

[0022]FIG. 1 shows a schematic representation of a combined cycle power plant. In essence, a combined cycle power plant 1 comprises a gas turbine 2 that can be operated with fossil fuels. This gas turbine 2 comprises a compressor part 3 in which air is heated and compressed, a combustion chamber 4 in which the air from the compressor part 3 is mixed with fuel and ignited, and a turbine part 5 in which—in various stages consisting of guide vanes and rotor blades that are not shown—the hot exhaust gases turn a rotor. A shaft 6 transfers this rotation to a generator 7. The generator 7 then supplies a supply grid with electrical energy (not shown).

[0023]The hot exhaust gases from the gas turbine 2 are fed into a steam generator 8. In this steam generator 8, fresh steam is generated by means of a line 9 and is then fed via a steam turbine fresh steam line 10 into a high-pressure turbine section 11. An HP valve 12 is arranged in the steam turbine fresh steam line 10. The steam leaving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com