Modular drilling fluid control system

a fluid control system and module technology, applied in the direction of drawing-off water installations, water supply installations, borehole/well accessories, etc., can solve the problems of increasing the design time, introducing errors into the system, and the drilling rig may not be in a favorable environment,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention relates to a drilling fluid control system for on-shore drilling environments having subsystem modules with standardized interfaces. As used herein, a slurry refers to a mixture of drilling fluid and solids.

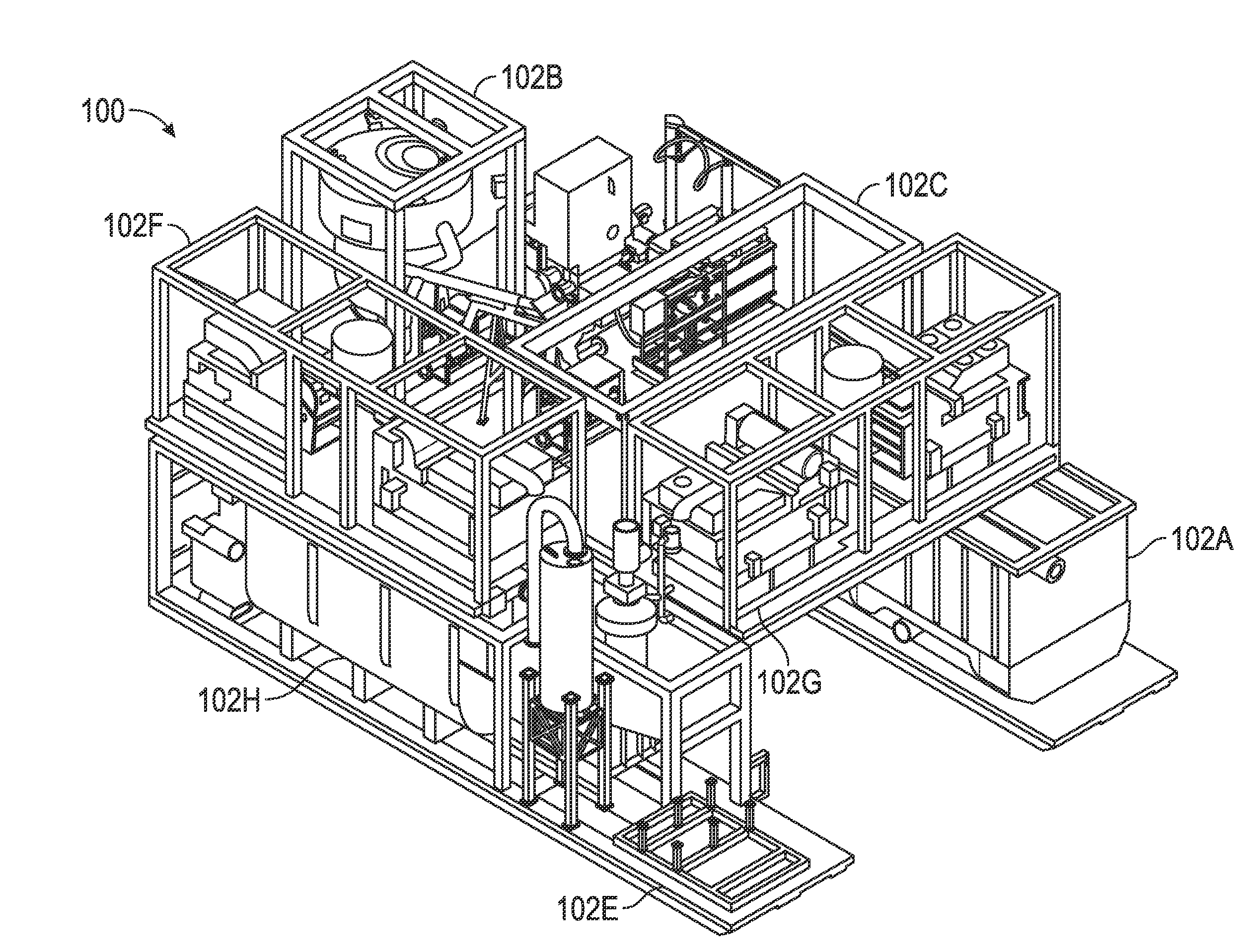

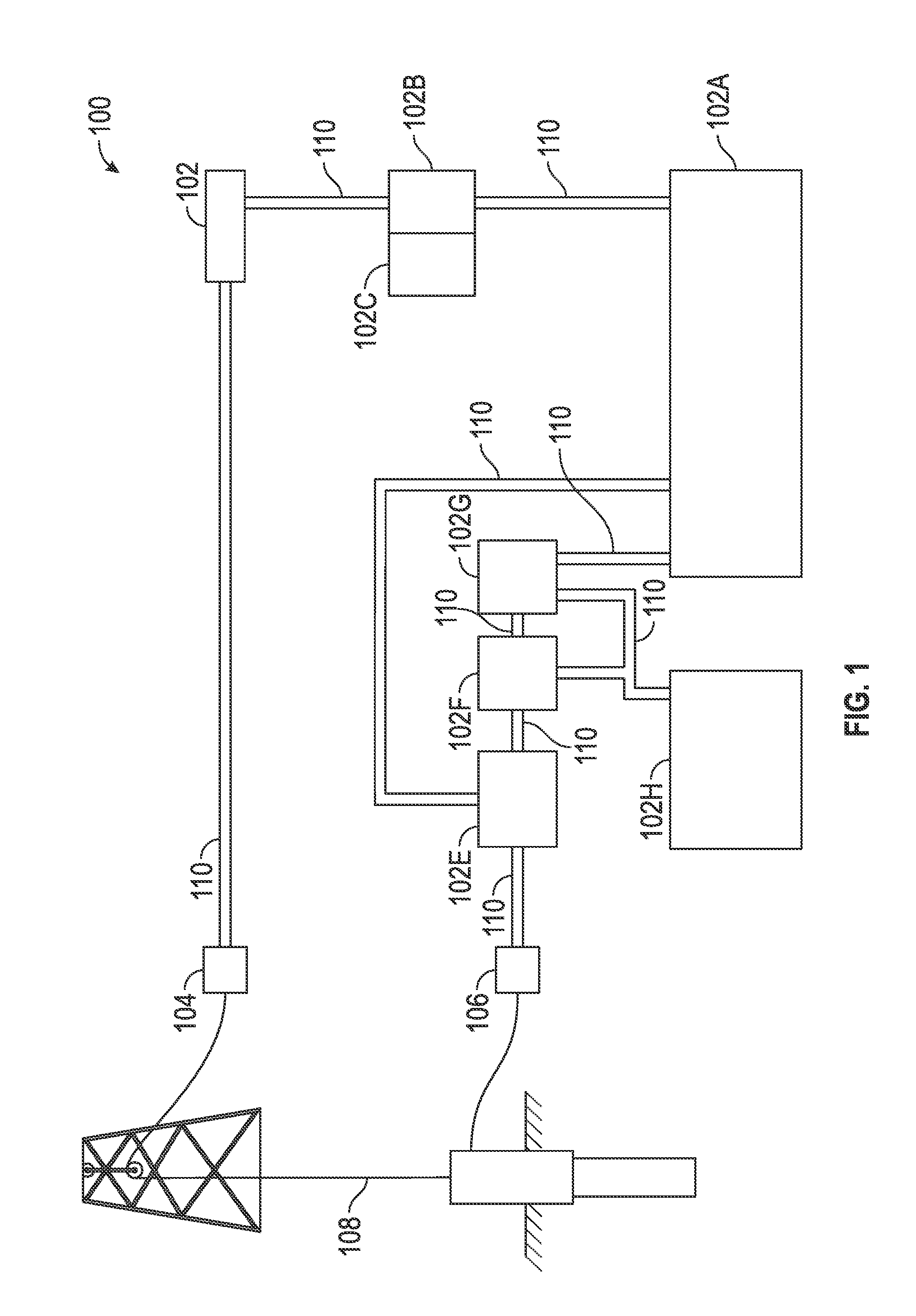

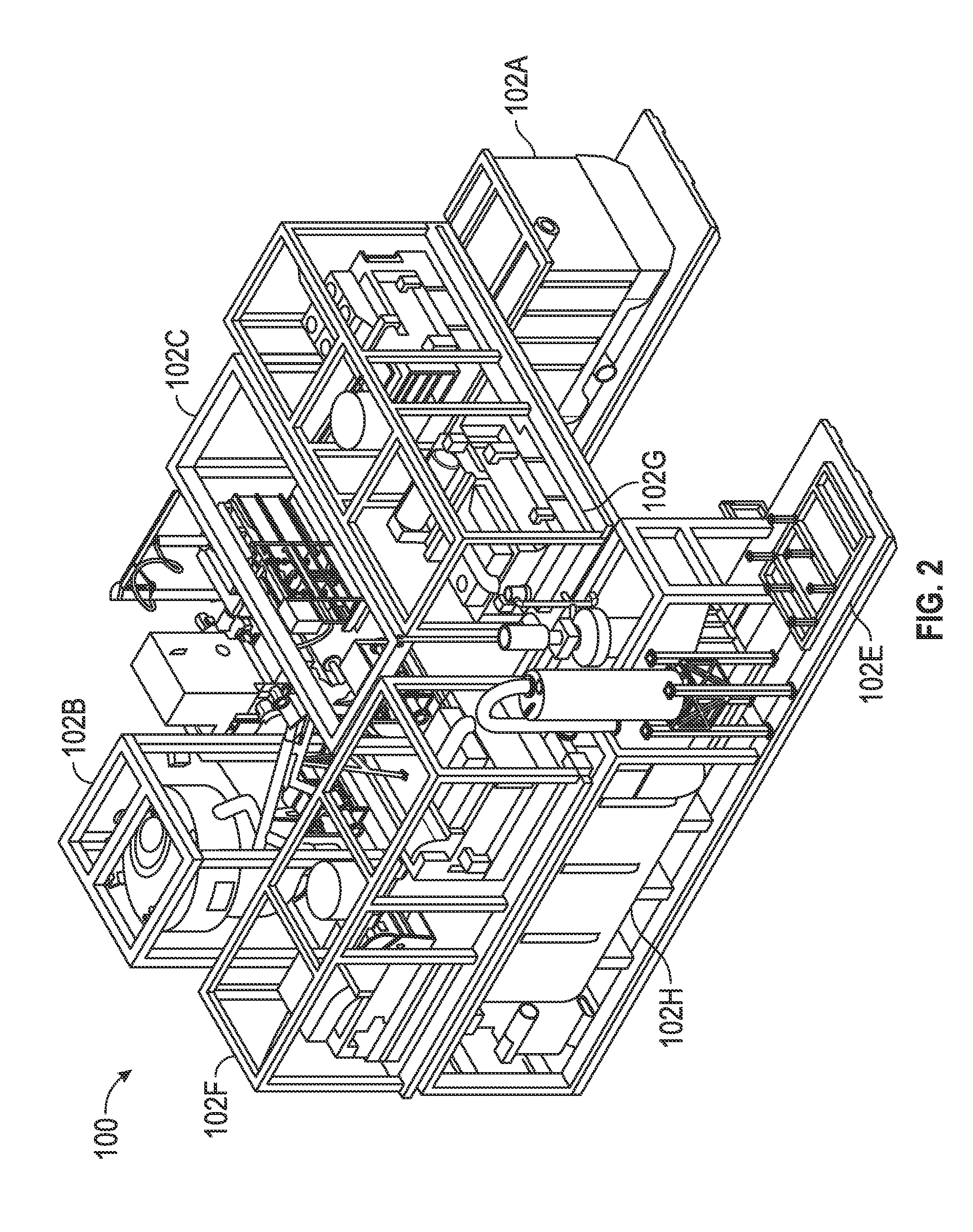

[0021]FIG. 1 and FIG. 2 generally illustrate an embodiment of a drilling fluid control system 100. The drilling fluid control system 100 may have subsystem modules 102A-102H and an output 104, an input 106 and interfacing conduit 110. The subsystem modules 102A-102H may include an active mud pit module 102A, a mud mixing module 102B, a chemical storage module 102C, a rig pump module 102D, a back pressure control module 102E, a primary shaker module 102F, a secondary shaker module 102G and / or a shaker pit module 102H. Other modules may include a dryer module (not shown) and / or an operator module (not shown). However, the present invention is not limited to the subsystem modules 102A-102H. The subsystem modules 102A-102H required for a particular embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com