Method and lift jet floatation system for shaping thin glass

a technology of floatation system and glass, which is applied in the direction of glass reforming apparatus, glass making apparatus, glass making tools, etc., can solve the problems of glass bending between the nozzles, glass tends to distort and bend between the nozzles, and is constantly changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

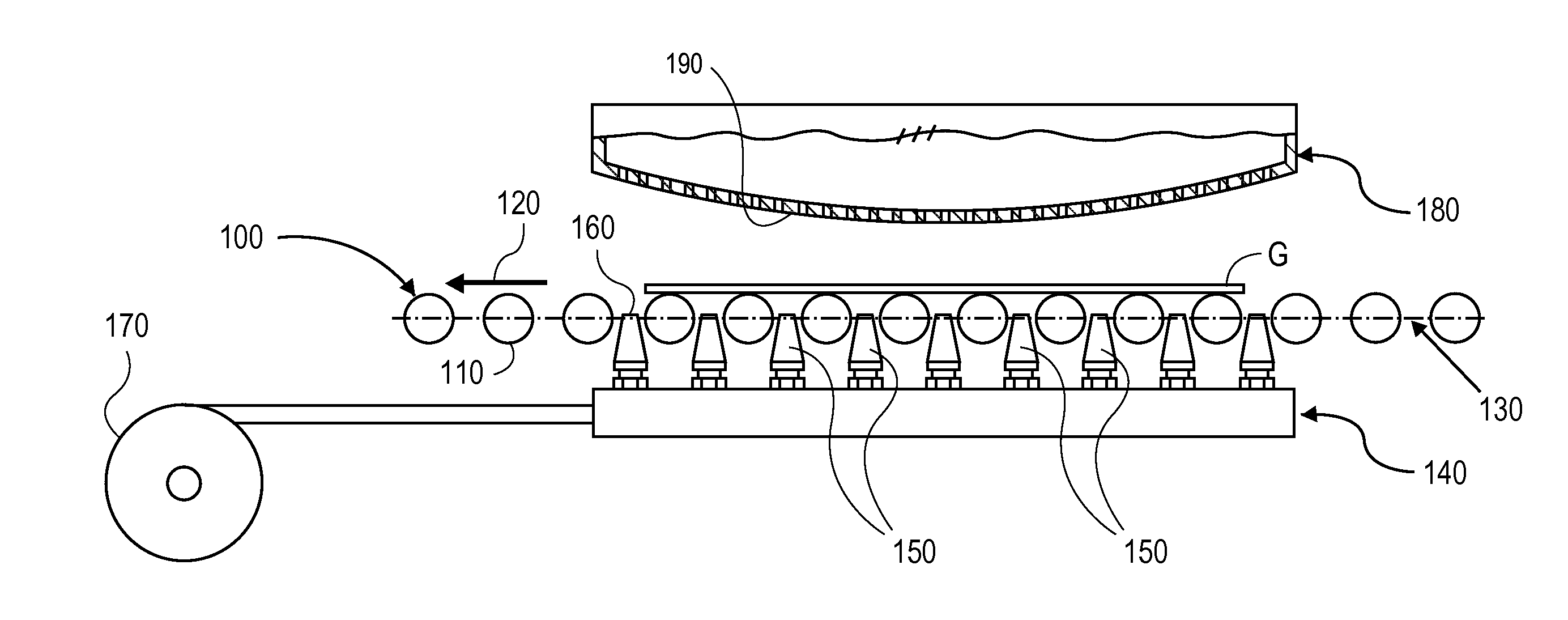

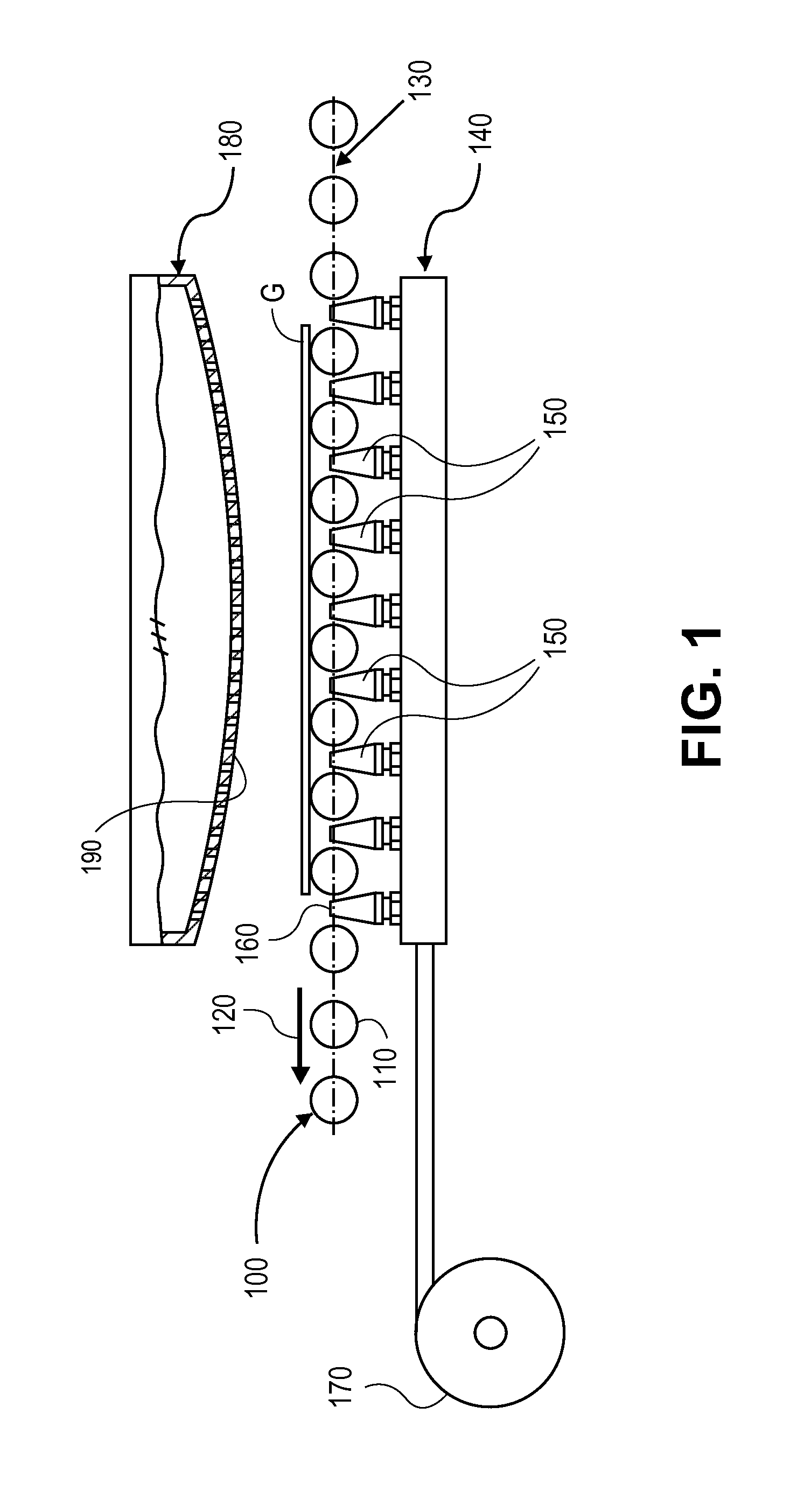

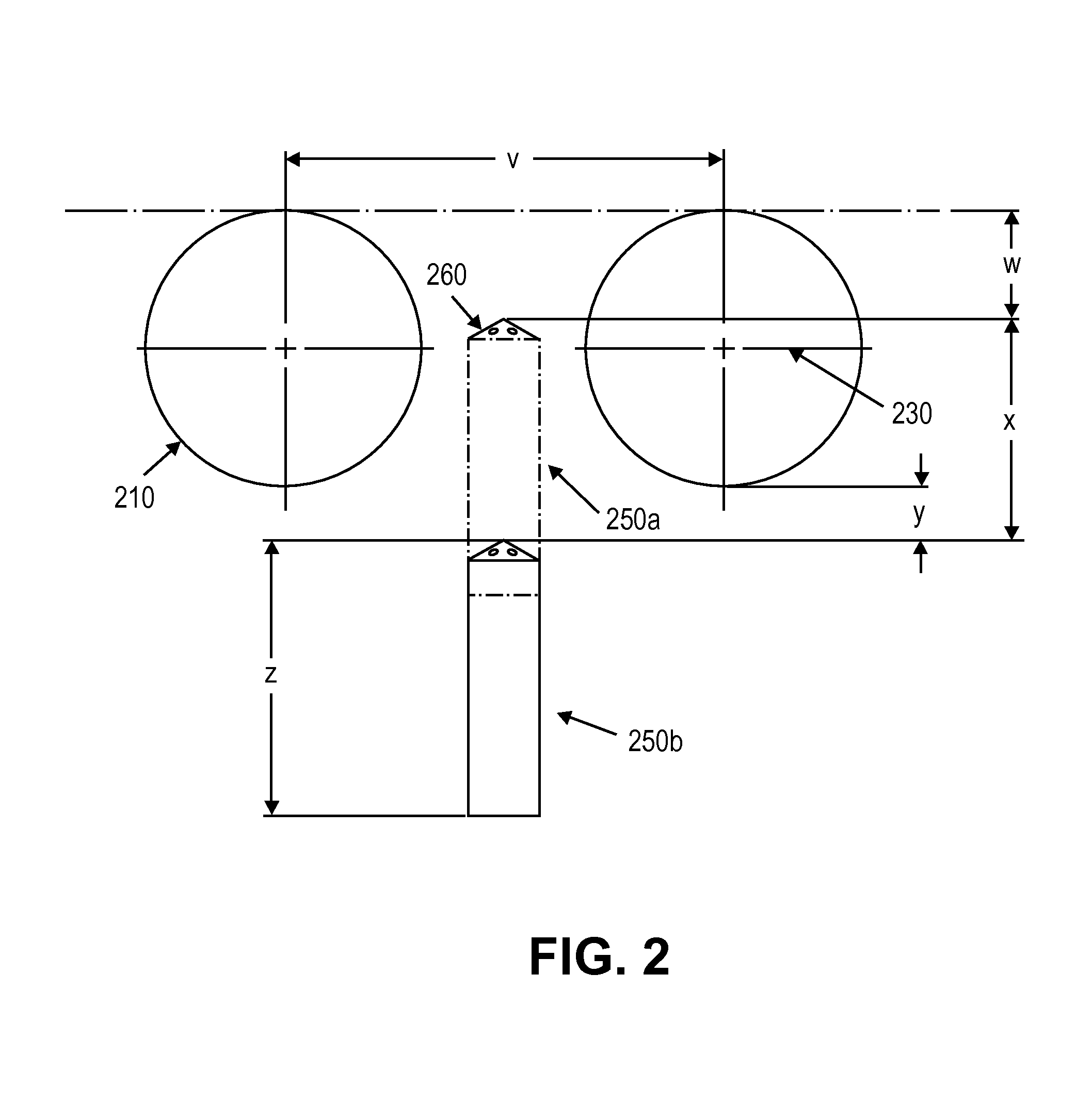

[0018]Disclosed herein is a lift jet floatation system for shaping a glass sheet comprising a roll conveyor comprising a plurality of rollers for conveying the glass sheet along a plane, the plurality of rollers having a centerline substantially parallel to the plane; a lift jet array comprising a plurality of nozzles, one or more of the plurality of nozzles comprising a tip having a plurality of orifices; and a shaping mold, wherein the roll conveyer is positioned substantially between the lift jet array and the shaping mold, and wherein the lift jet array is positioned substantially below the roll conveyor such that each nozzle tip is located above the centerline of the plurality of rollers.

[0019]Also disclosed herein is a system for lifting or shaping a glass sheet comprising a roll conveyor comprising a plurality of rollers for conveying the glass sheet along a plane, the plurality of rollers having a centerline substantially parallel to the plane, and an array of lift nozzles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com