Method for providing multiple fractures in a formation

a technology of multiple fractures and formations, applied in the direction of fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problem of limited rapid growth of fractures, and achieve the effect of reducing the cost of diverter material, minimizing damage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

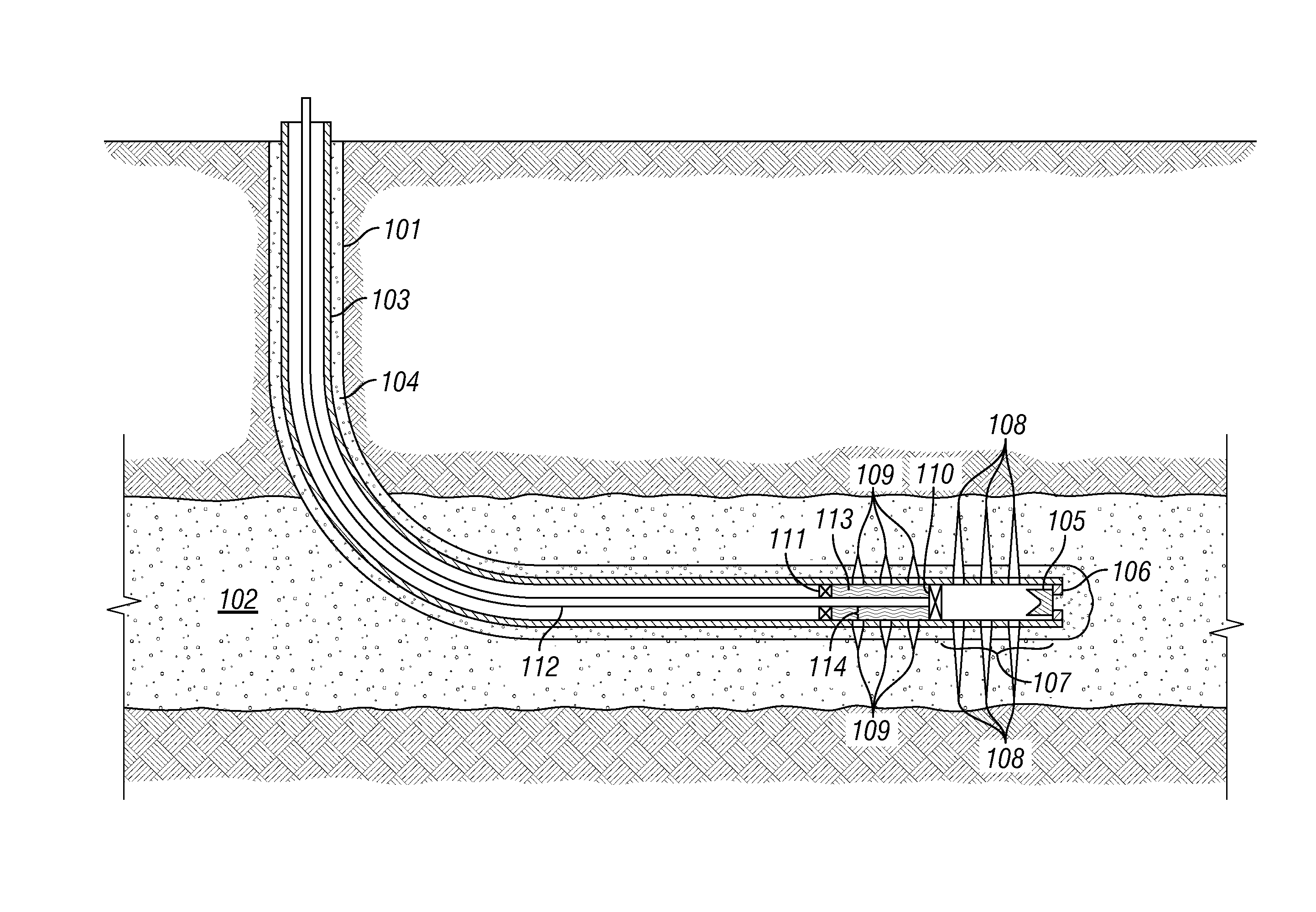

Image

Examples

example 1

[0038]Diverter material was obtained from ICO Polymers North America, Inc, located in Akron, Ohio. The material was a polylactate biodegradable polymer with a size distribution of 1 to 2830 micron. In a horizontal well bore that had been drilled, cased, and all but the last three stages were fraced by normal procedures. The last three stages, at the heel end of the wellbore, were combined into one stage to test the effectiveness of one embodiment of the present invention. This section of the wellbore was about eight hundred feet long. This segment was peforated with nine clusters of perforations, the clusters being separated by about 84 feet. The amount of fracturing fluid and proppant used was the normal amount for three stages, or three times the amount used for the previous individual stages. The total amount of proppant pumped was about 900,000 pounds. The proppant and fluid was injected in three roughly equal batches, each batch separated by a slug of diverter material in fluid...

example 2

[0039]For this example, the diverter material was commercially available material, Biovert, from Halliburton Energy Services, Inc., of Houston, Tex. The well was a well equipped with a fiber optic sensor capable of measuring a complete temperature and acoustic profile within the well. With the complete acoustic and temperature profile, as a function of time, the distribution of fracturing fluid going into different perforations within a cluster may be calculated. Typically, without the present invention, it is observed that when a cluster of six perforations are fractured, there will be one to three dominate fractures, with three to five fractures receiving considerably less proppant. Therefore, normal procedures would be to not attempt to fracture more than three clusters per stage. This results in more effective fractures within the wellbore, and more predictable placement of fractures, but increases completion costs. To demonstrate the effectiveness of one embodiment of the prese...

example 3

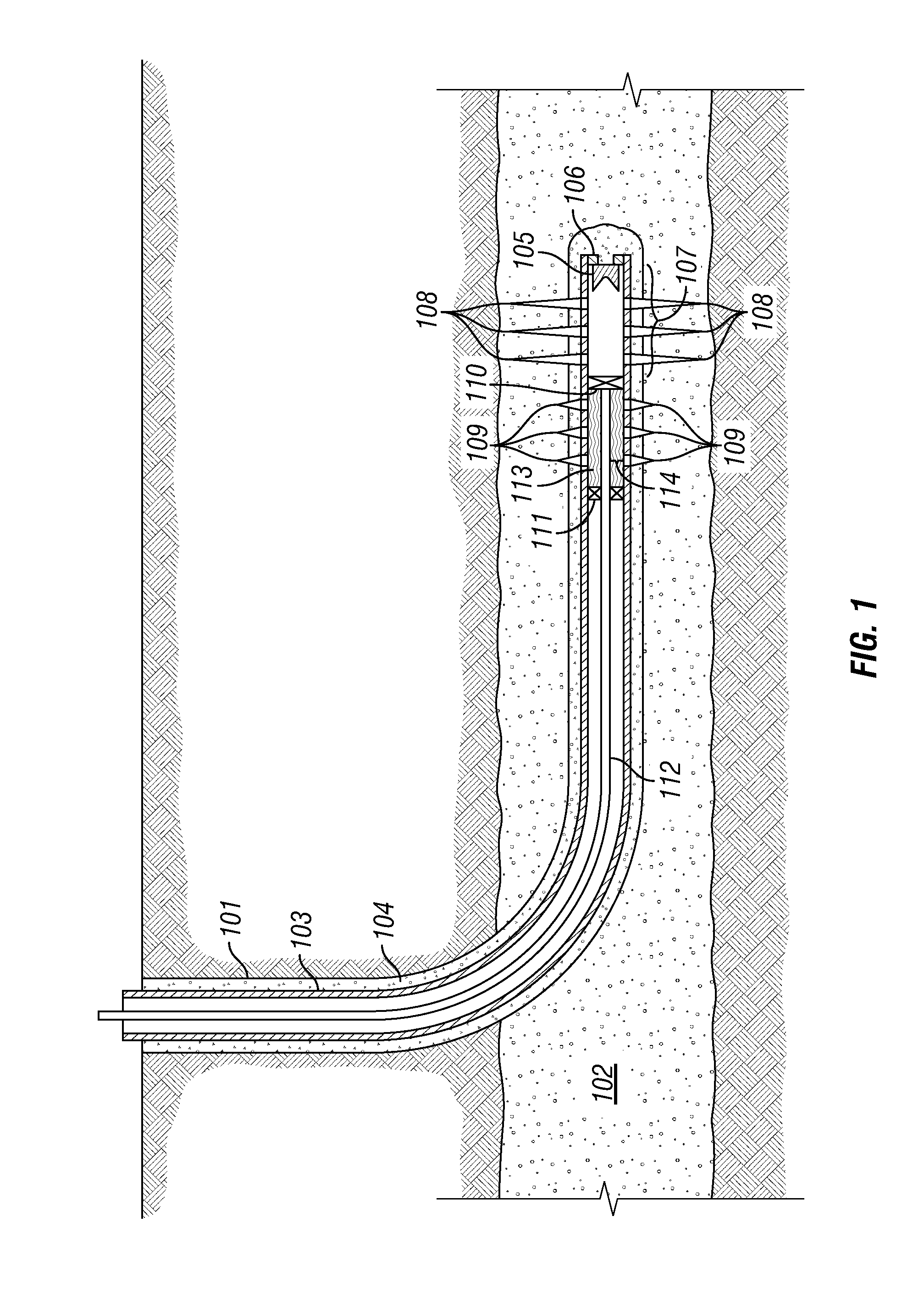

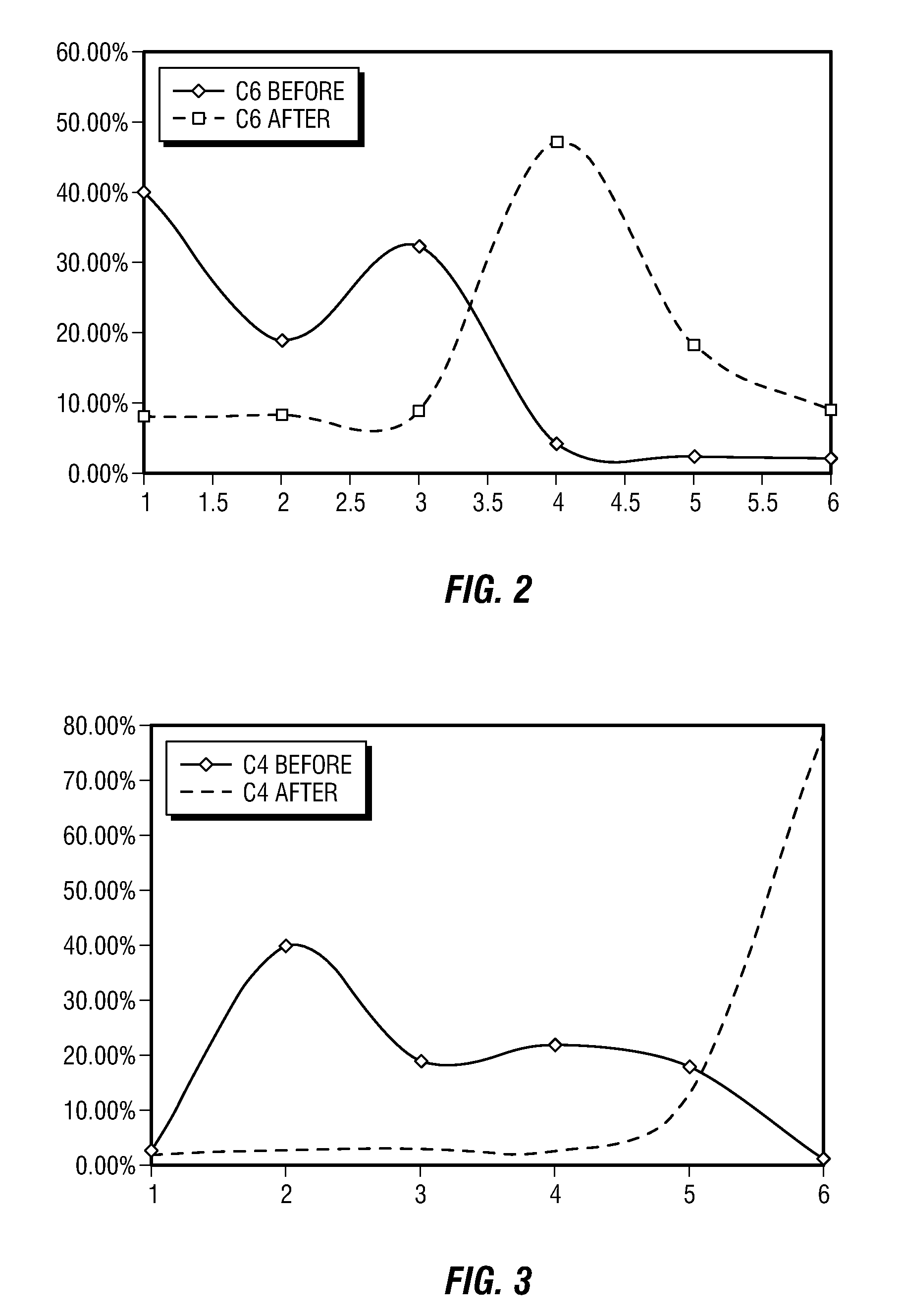

[0040]Another test to determine if open clusters could be blocked to divert fracture fluids into unopened clusters of perforations in a horizontal well in the Eagle Ford formation. The diverter used was commercially available BioVert from Halliburton. Referring now to FIG. 2, the x-axis is the number for clusters in one stage. The Y axis is the percentage of fracturing fluid and slurry taken by each clusters. During the job, the total fluid and slurry volume were divided into two portions. The first portion was pumped as a regular fracturing procedure. The solid line indicates the percentage of fluid and slurry taken by each cluster during the first portion of the treatment calculated from fiber optic temperature sensor data. The results show that during the first portion of the treatment, there are four clusters taking fluid and slurry, one cluster was taking more than the others. Two clusters did not take any fluids. A diverter slug was pumped after the first portion of treatment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com