Gas turbine engine ducting arrangement having discrete insert

a gas turbine engine and insert technology, applied in the direction of machines/engines, liquid fuel engines, lighting and heating apparatus, etc., can solve the problems of significant pressure differences (up to six atmospheres) and the resulting force acting on the exterior surface of the duct arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

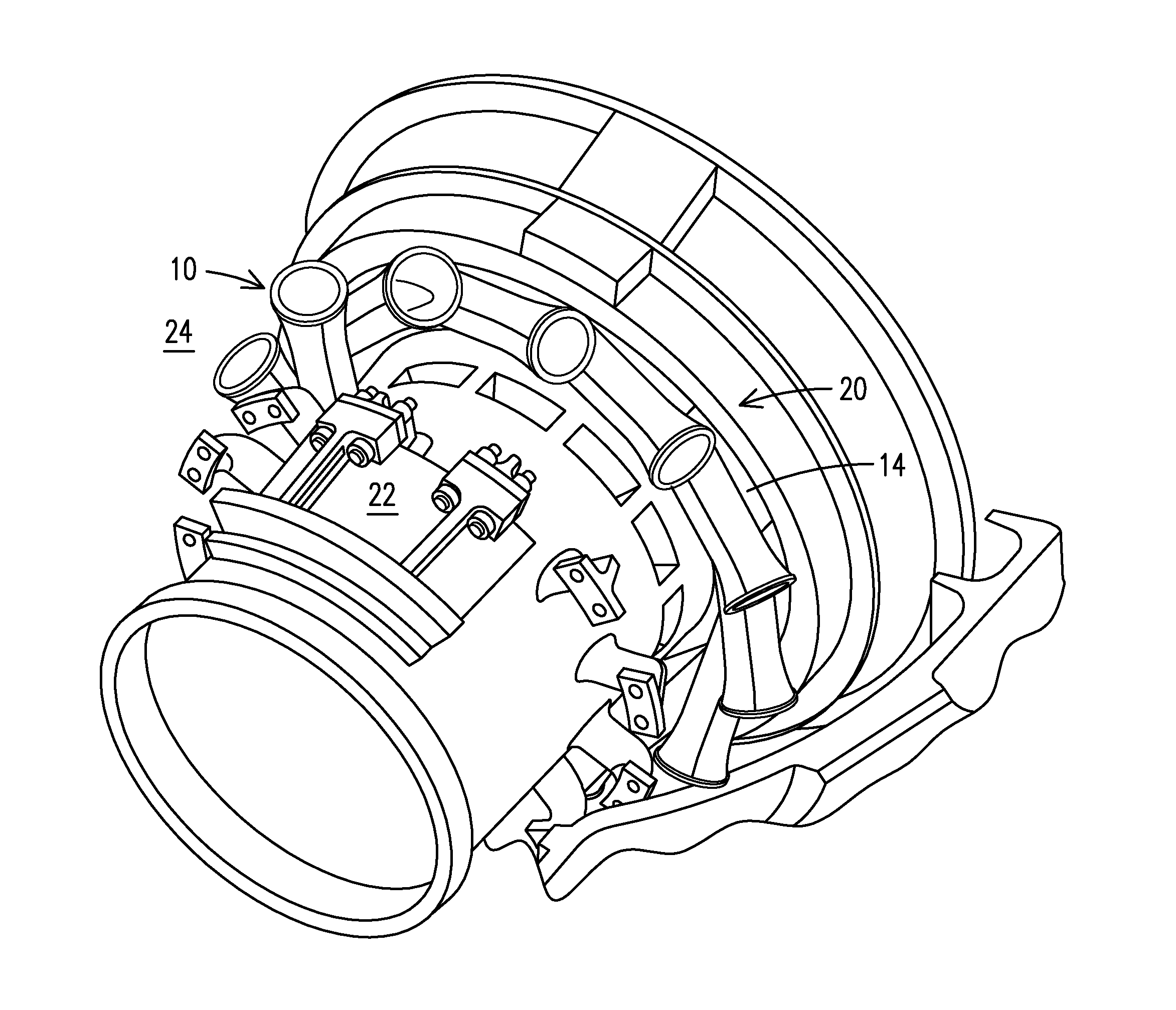

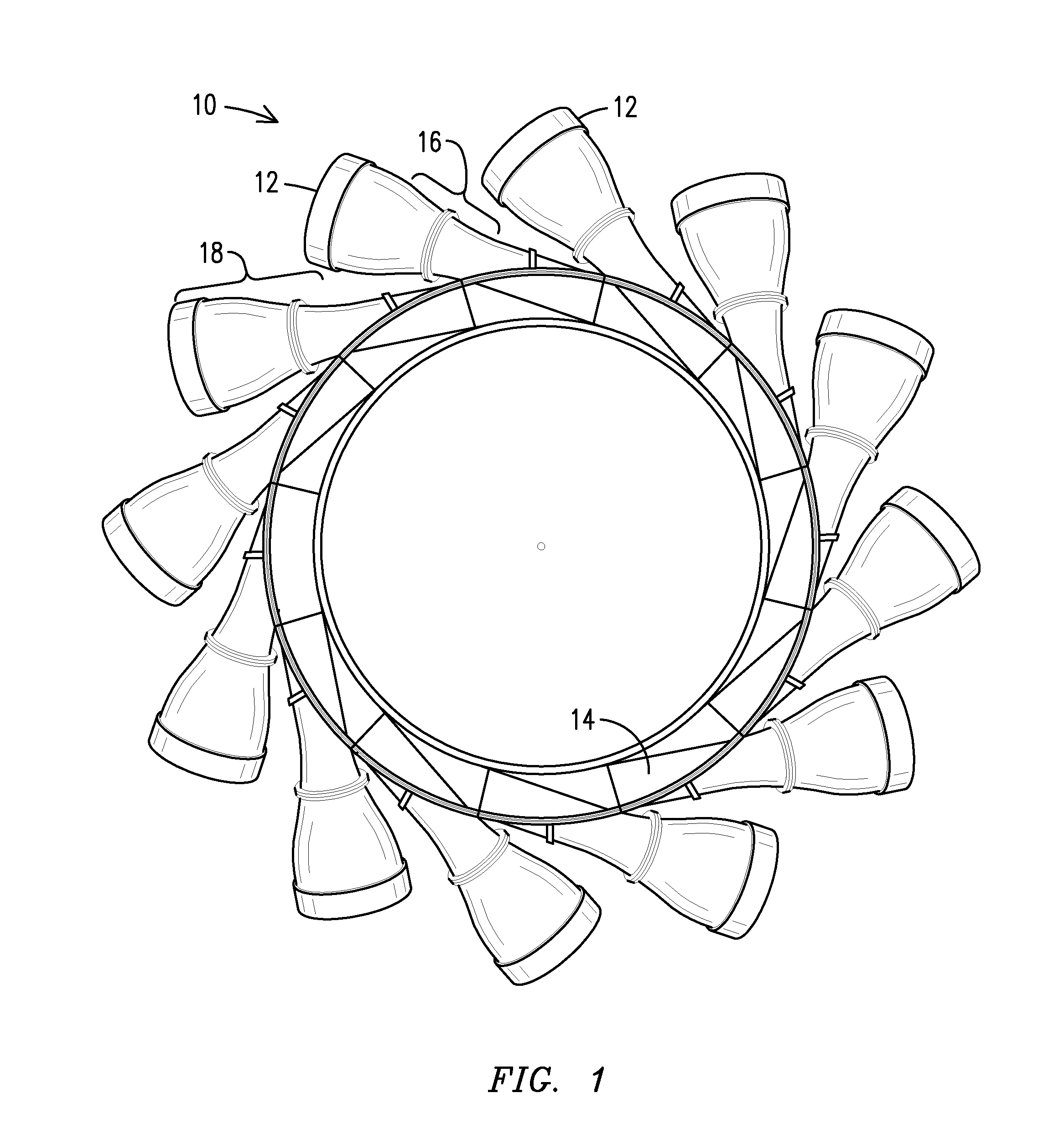

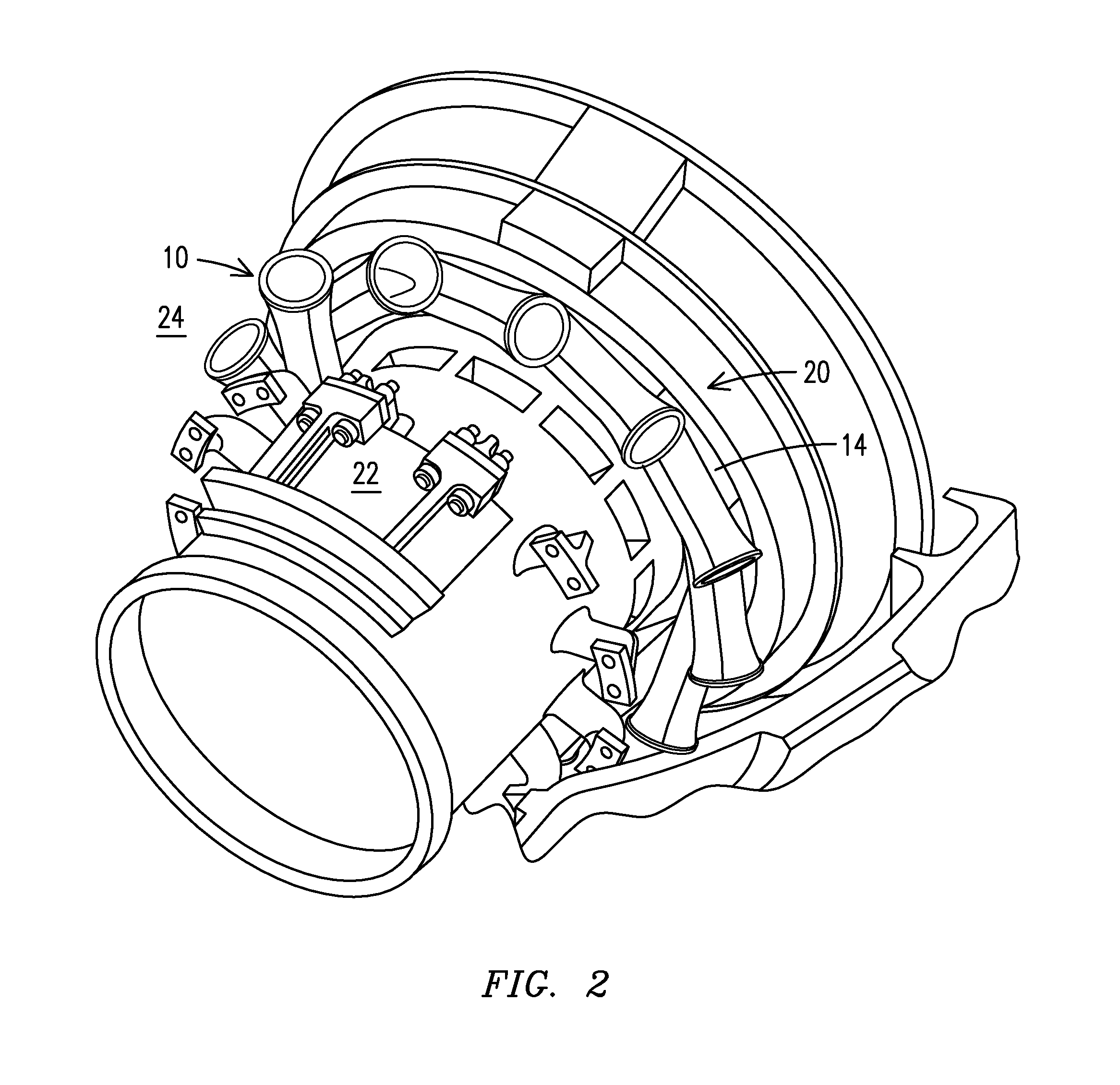

Image

Examples

Embodiment Construction

[0013]The present inventors have recognized at least one form of deformation that may occur when using one exemplary embodiment of a ducting arrangement and have identified a region of the ducting arrangement likely to experience substantial mechanical stresses as a result of this deformation. The inventors have further recognized that this region of relatively great mechanical stress is also a region of relatively great thermal stress which compounds the problem.

[0014]To accommodate this localized region of high mechanical and thermal stresses, and thereby extend the service life of the ducting arrangement, the inventors have proposed an innovative arrangement that lowers the mechanical stresses in the area. This, in turn, permits the use of an insert having a material that is better suited thermally for the local region, and this reduces an amount of cooling air that is required for the local region which, in turn, increases engine efficiency. Reducing the stresses at this locatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com