Producing Hydrocarbons from a Formation

a technology of hydrocarbons and formations, applied in the direction of fluid removal, survey, borehole/well accessories, etc., can solve the problems of reduced hydrocarbon production rate, limited ability, and decreased production ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

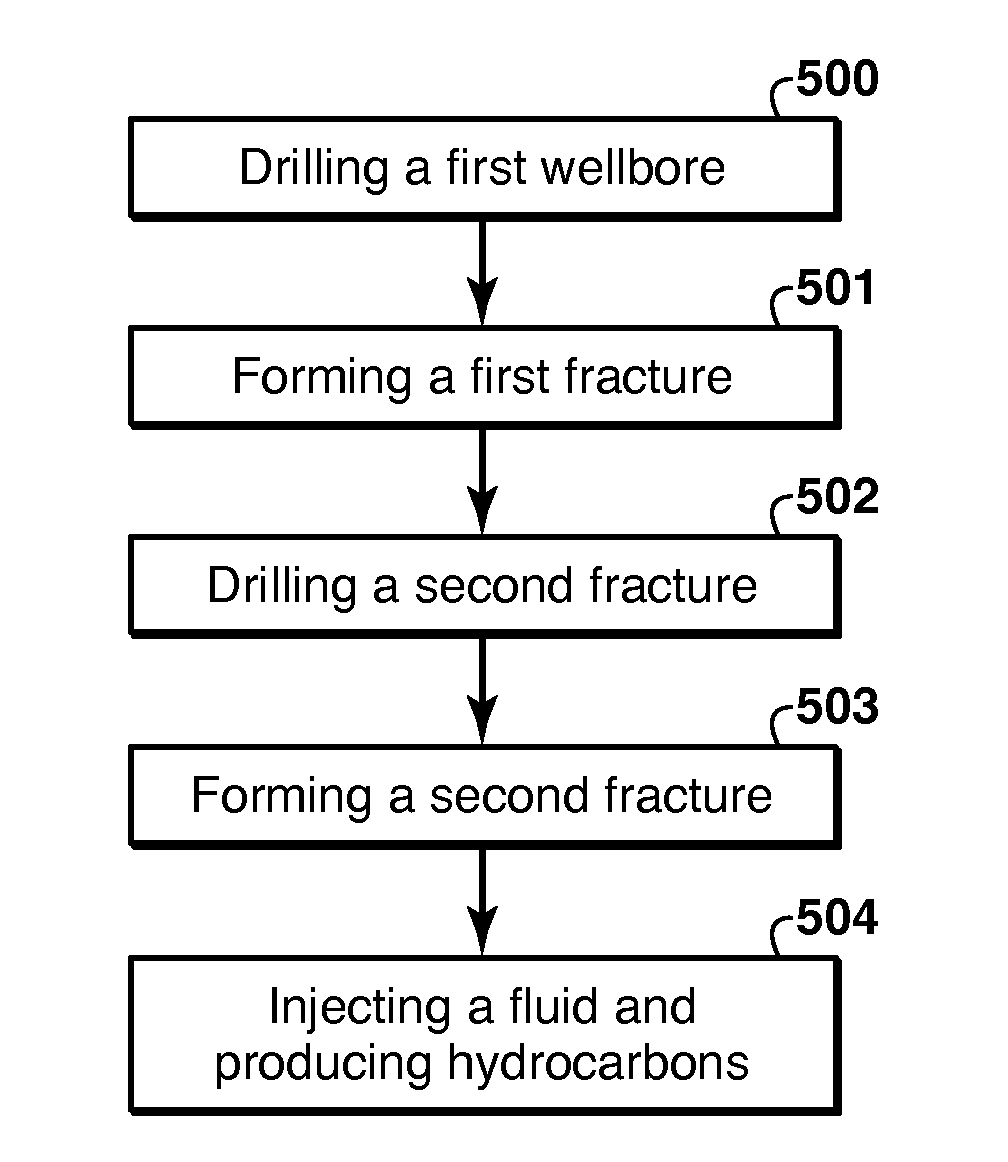

Method used

Image

Examples

Embodiment Construction

[0003]The disclosure relates generally to the field of producing hydrocarbons from a formation.

[0004]2. Description of Related Art

[0005]This discussion is believed to assist in providing a framework to facilitate a better understanding of particular aspects of the present disclosure. Accordingly, it should be understood that this section should be read in this light, and not necessarily as admissions of prior art.

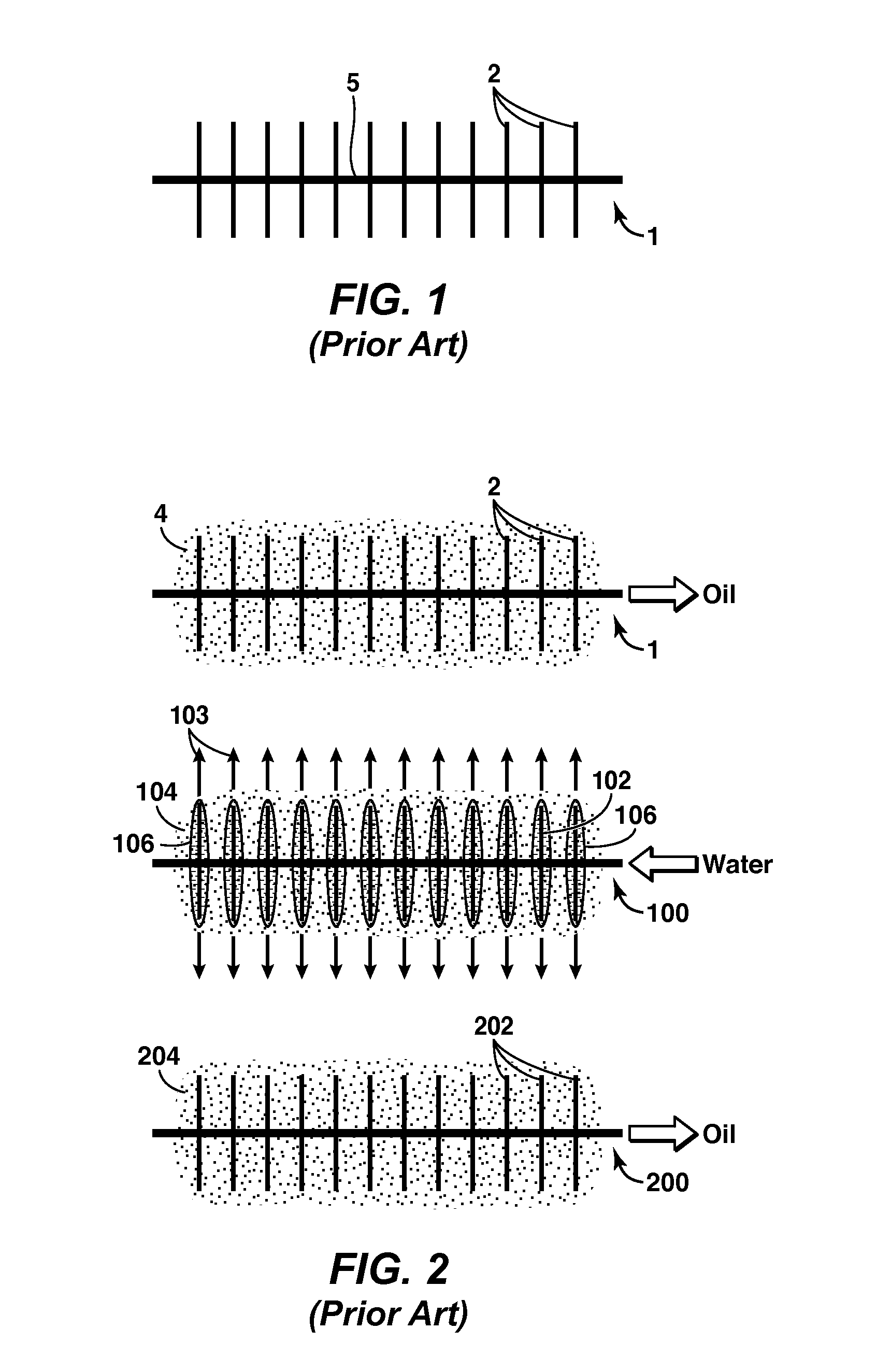

[0006]Substantial volumes of hydrocarbons exist in low-permeability and high-permeability formations around the world. Low-permeability formations may be formations that are near horizontal wells with multiple fracture stimulations distributed along the well and required to produce fluids from the formation at economic rates. For example, low-permeability formations may be less than or equal to 10 millidarcies (mD) while high-permeability formations may be formations that are greater than 10 mD. Low-permeability formations may be predominantly sandstone, carbonate, or shale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com