Knuckle-jointed lance for internal cleaning and inspection of tubulars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

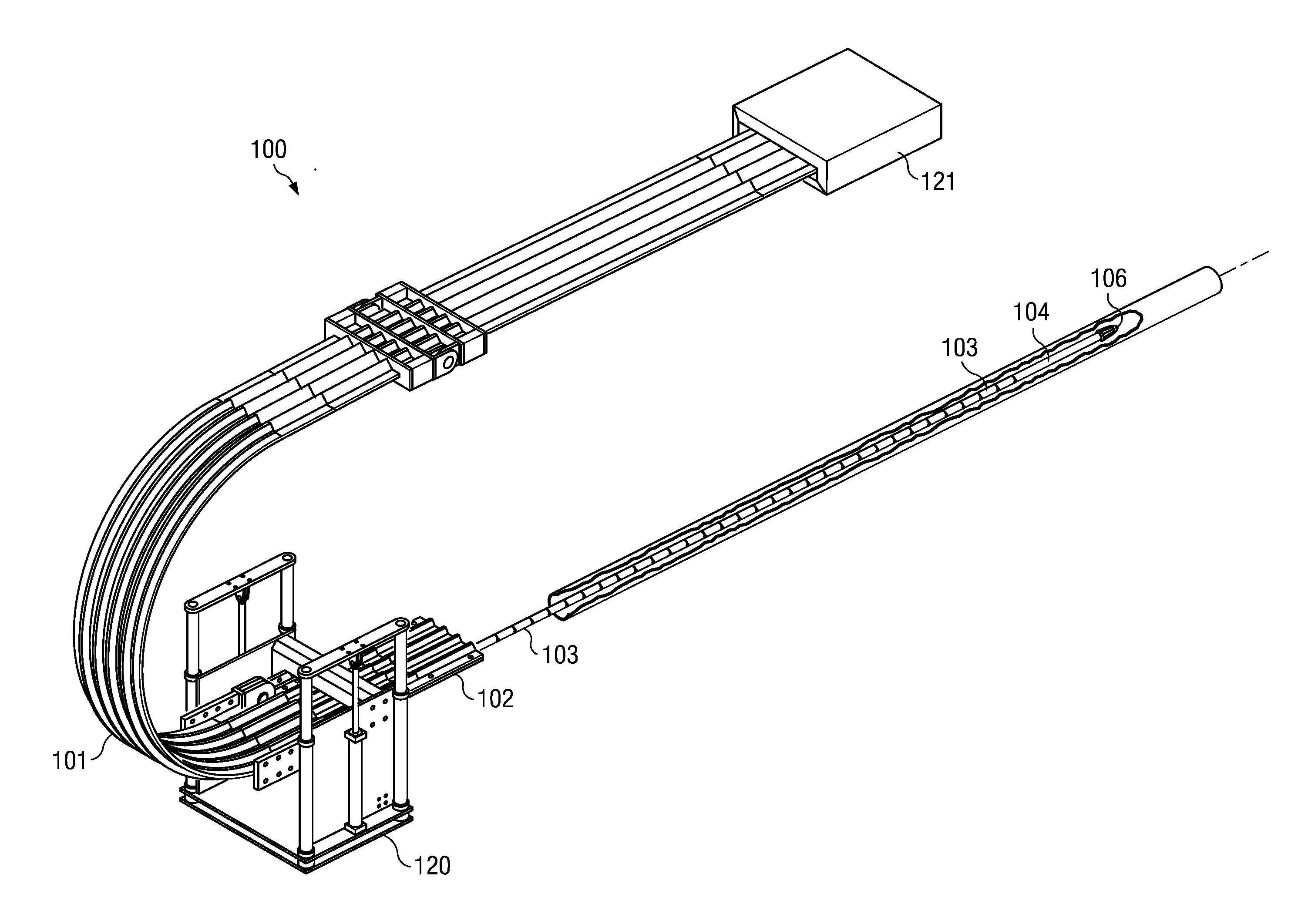

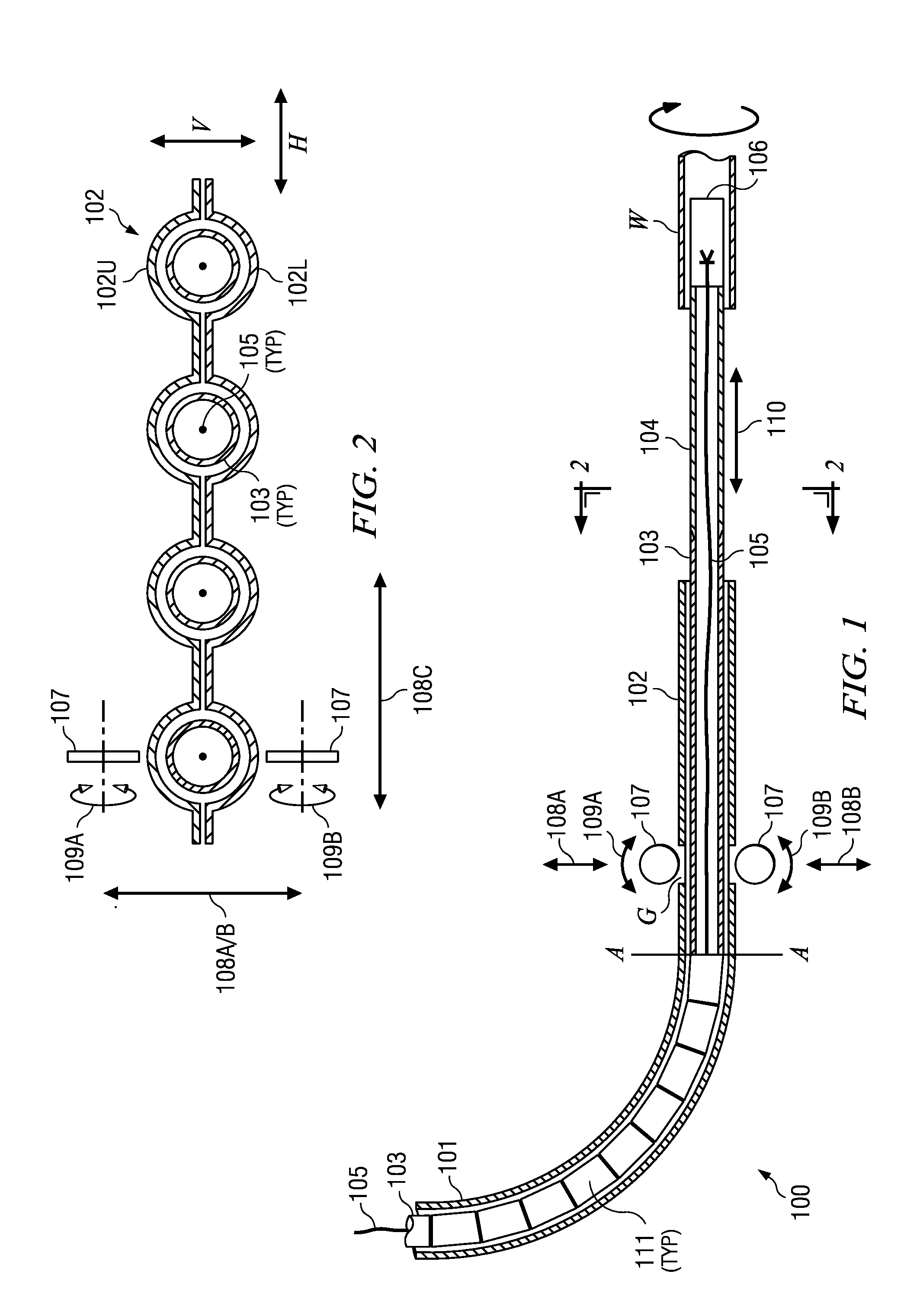

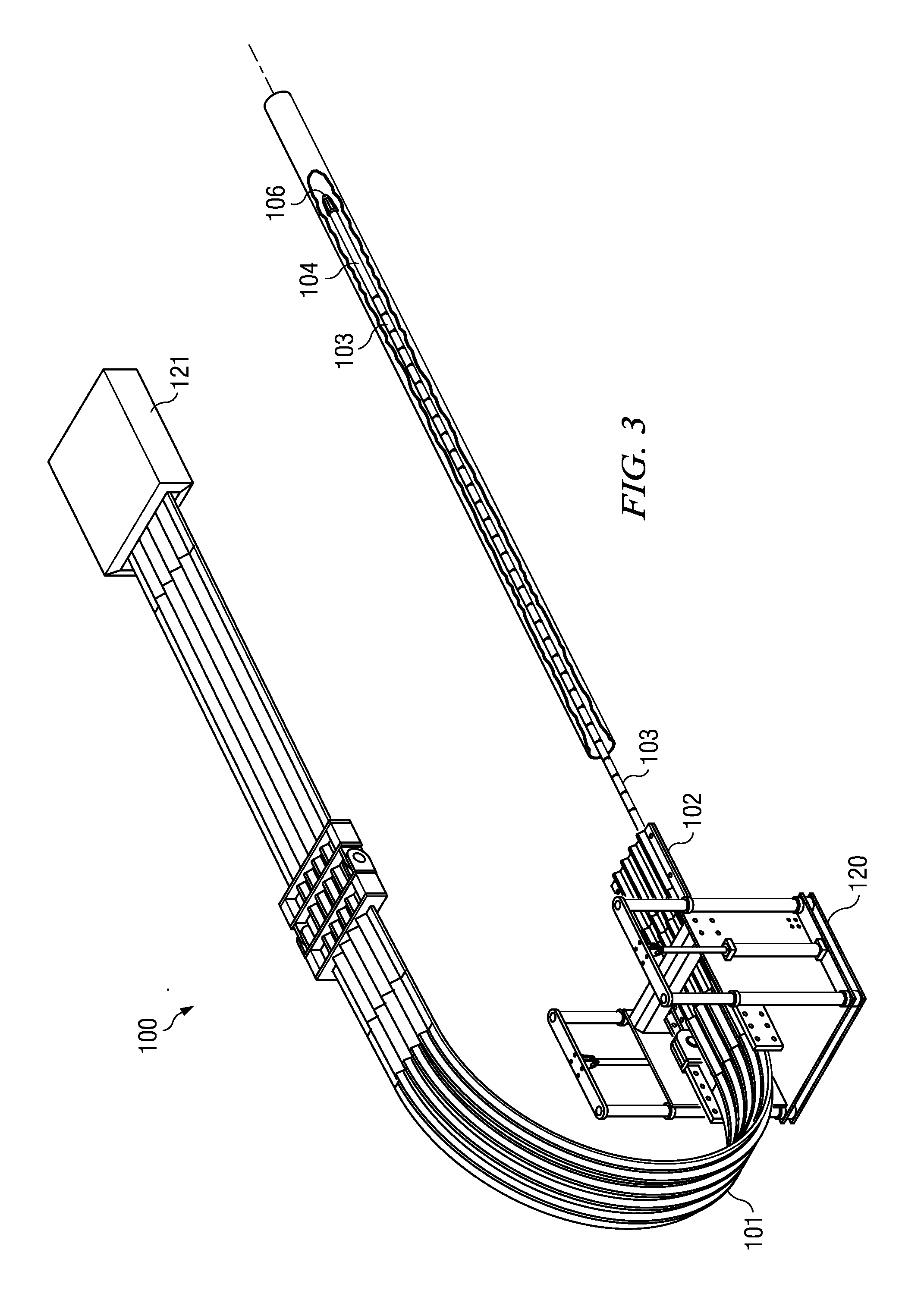

[0040]Reference is now made to FIGS. 1 through 13 and FIGS. 8 through 11 in describing the currently preferred embodiment of the MLI.

[0041]It will be understood that the MLI, in a currently preferred embodiment, has a number of cooperating parts and mechanisms, including the Knuckle Jointed Lancer (KJL). FIGS. 1 and 2 are a functional cross-sectional representation of some of the main components included in a currently preferred embodiment of the MLI, and depict how such components cooperate in the MLI assembly. As functional representations, they will be understood not to be to scale even in a general sense. Rather, it will be appreciated that a primary purpose of FIGS. 1 and 2 is to illustrate cooperating aspects of the MLI in a conceptual sense (rather in a more structurally accurate sense), in order to facilitate better understanding of other, more structurally accurate illustrations of the MLI and KJL in this disclosure.

[0042]FIG. 1 illustrates MLI assembly 100 generally in cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com