Air supply and conditioning system for a turbine system and method of supplying air

a technology of air supply and conditioning system and turbine system, which is applied in the direction of pump control, non-positive displacement fluid engine, pump control, etc., can solve the problems of part and installation cost, rather expensive heat exchanger,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

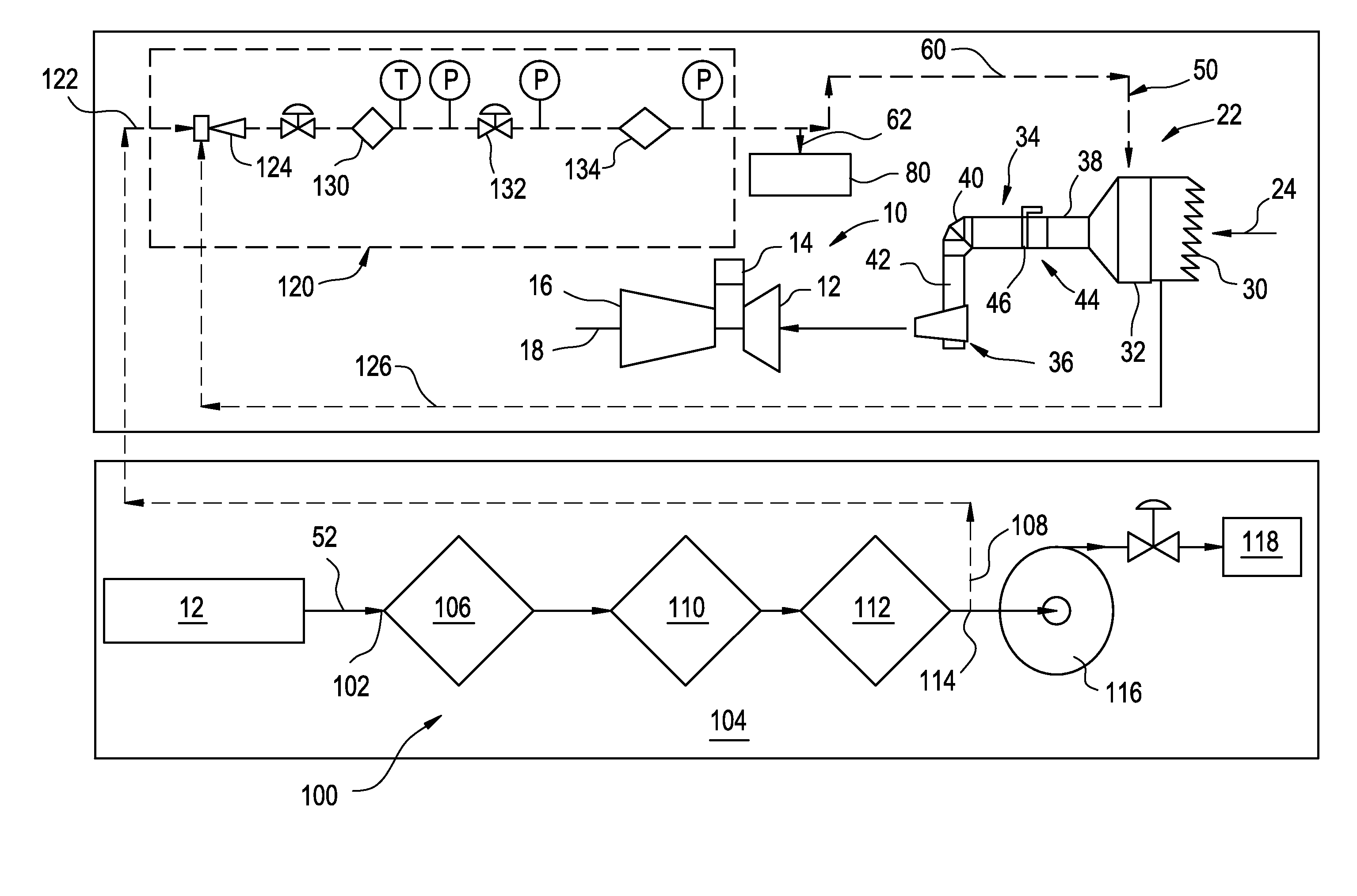

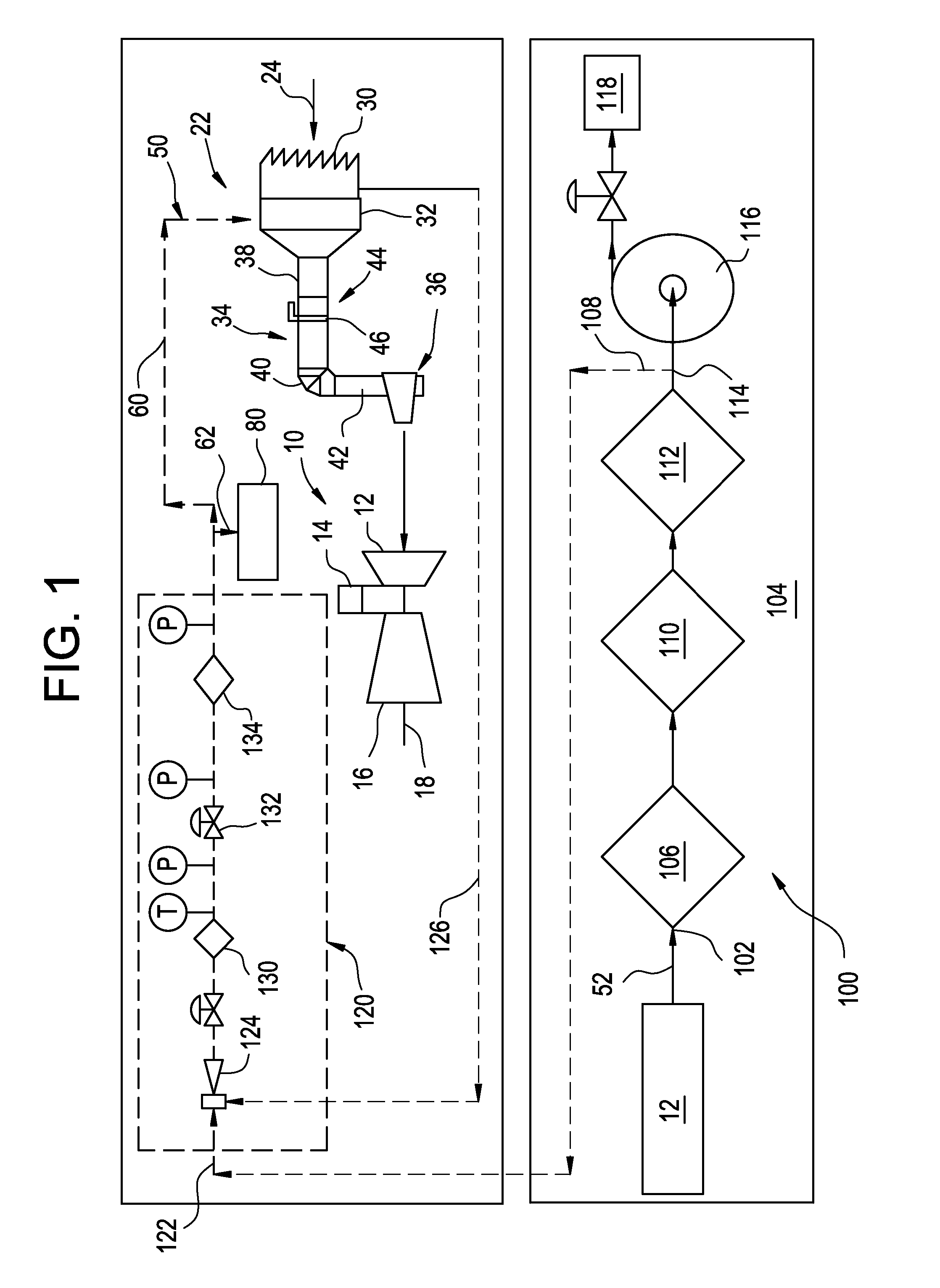

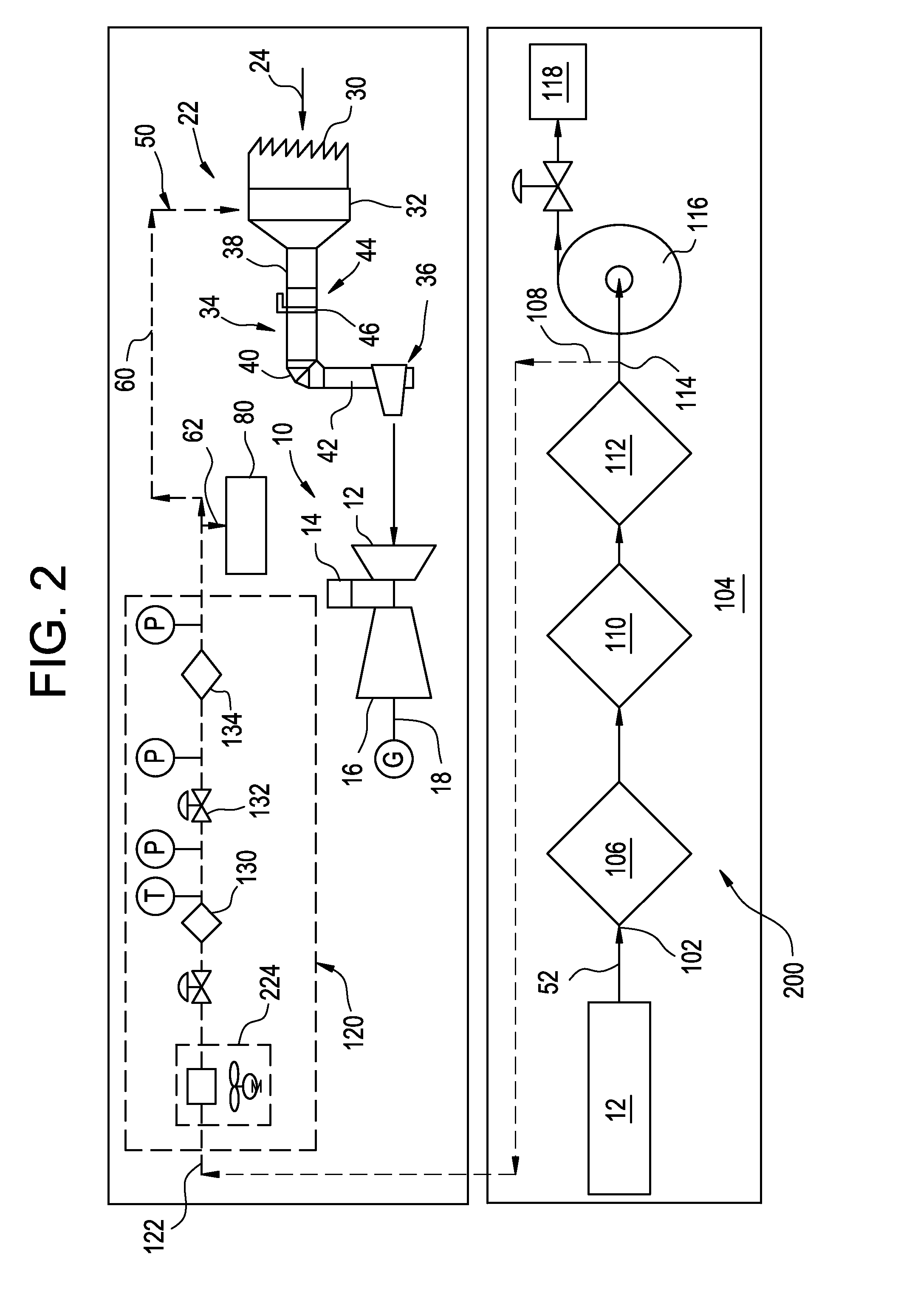

[0013]Referring to FIG. 1, a turbine system is schematically illustrated with reference numeral 10. The turbine system 10 includes a compressor 12, a combustor 14, a turbine 16, a shaft 18 and a fuel nozzle 20. The compressor 12 and the turbine 16 are coupled by the shaft 18. The shaft 18 may be a single shaft or a plurality of shaft segments coupled together to form the shaft 18. Additionally, an inlet filter assembly 22 ingests an airstream 24 that is filtered and routed to the compressor 12. The combustor 14 uses a combustible liquid and / or gas fuel, such as natural gas or a hydrogen rich synthetic gas, to run the gas turbine system 10.

[0014]The inlet filter assembly 22 includes an entry portion 30 for the airstream 24, where the entry portion 30 typically comprises one or more weather hoods or louvers. The entry portion 30 provides a path for the airstream 24 to enter an inlet filter compartment 32 from ambient surroundings. An inlet duct 34 is configured to contain and route th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com