Swash-plate-type compressor

a compressor and plate-type technology, applied in the direction of pump components, positive displacement liquid engines, machines/engines, etc., can solve the problems of reducing suction efficiency and the suction valve may not open at the desired timing, so as to suppress the pulsation and suction efficiency from being lowered, and the size of the compressor is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

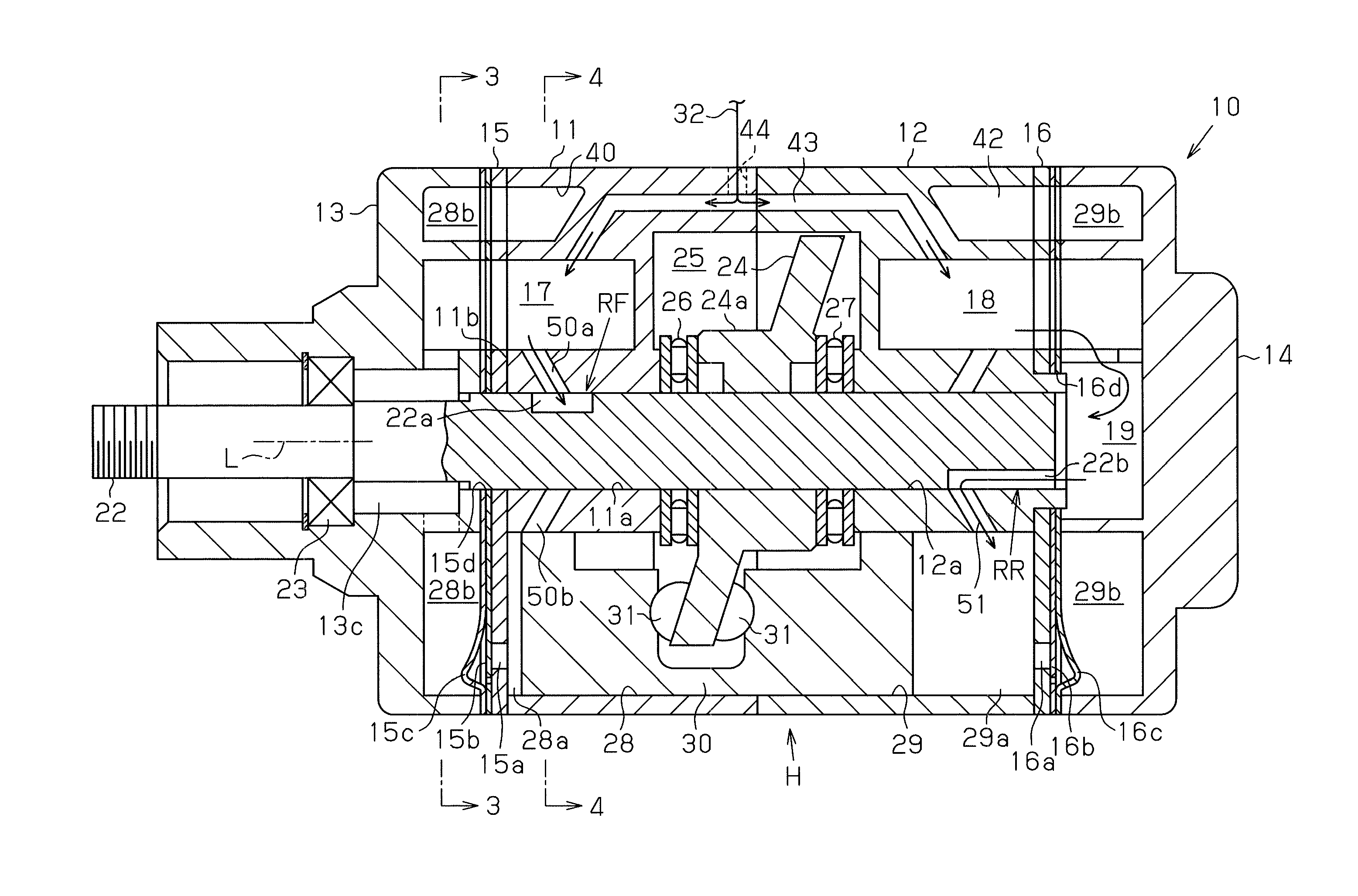

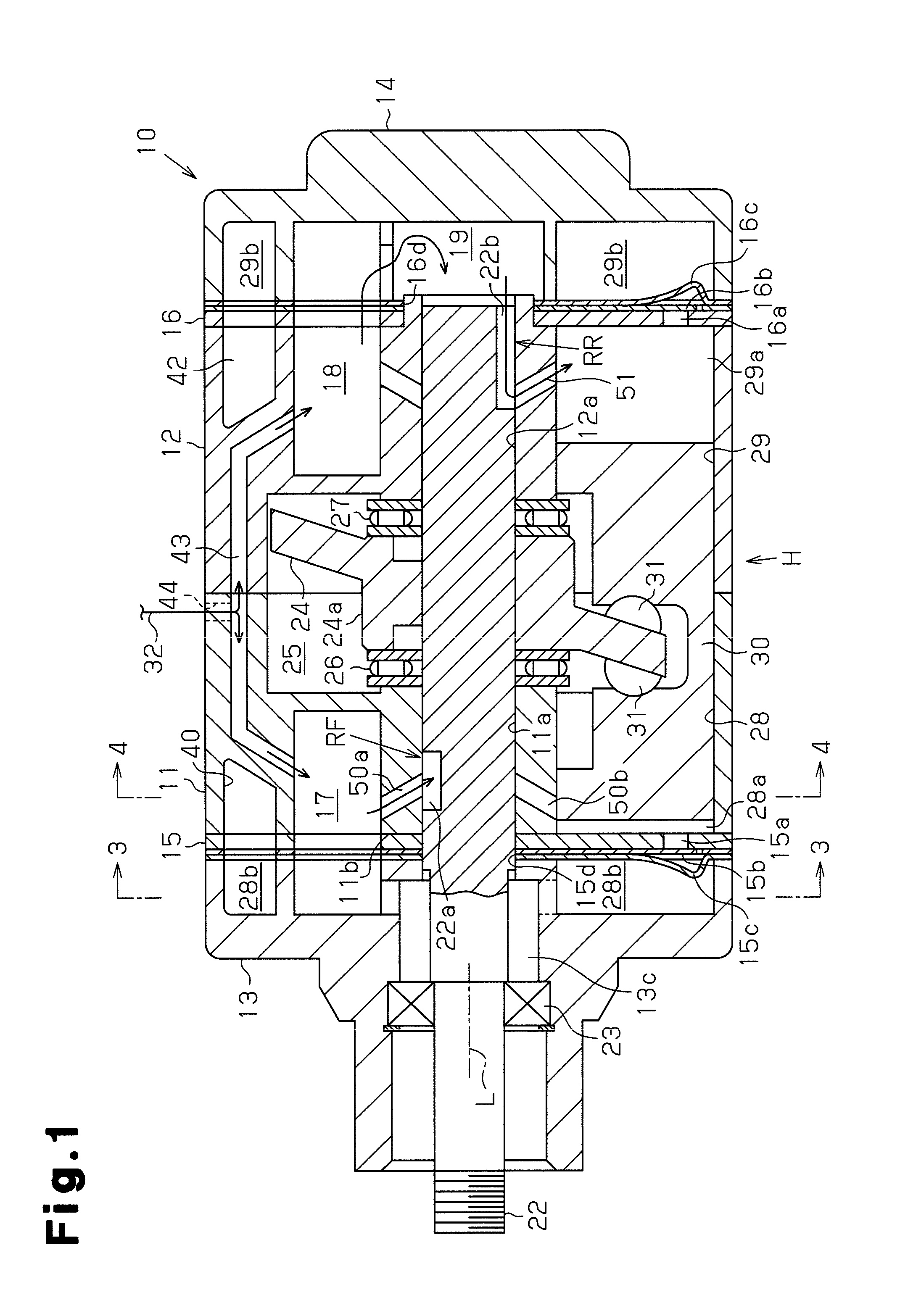

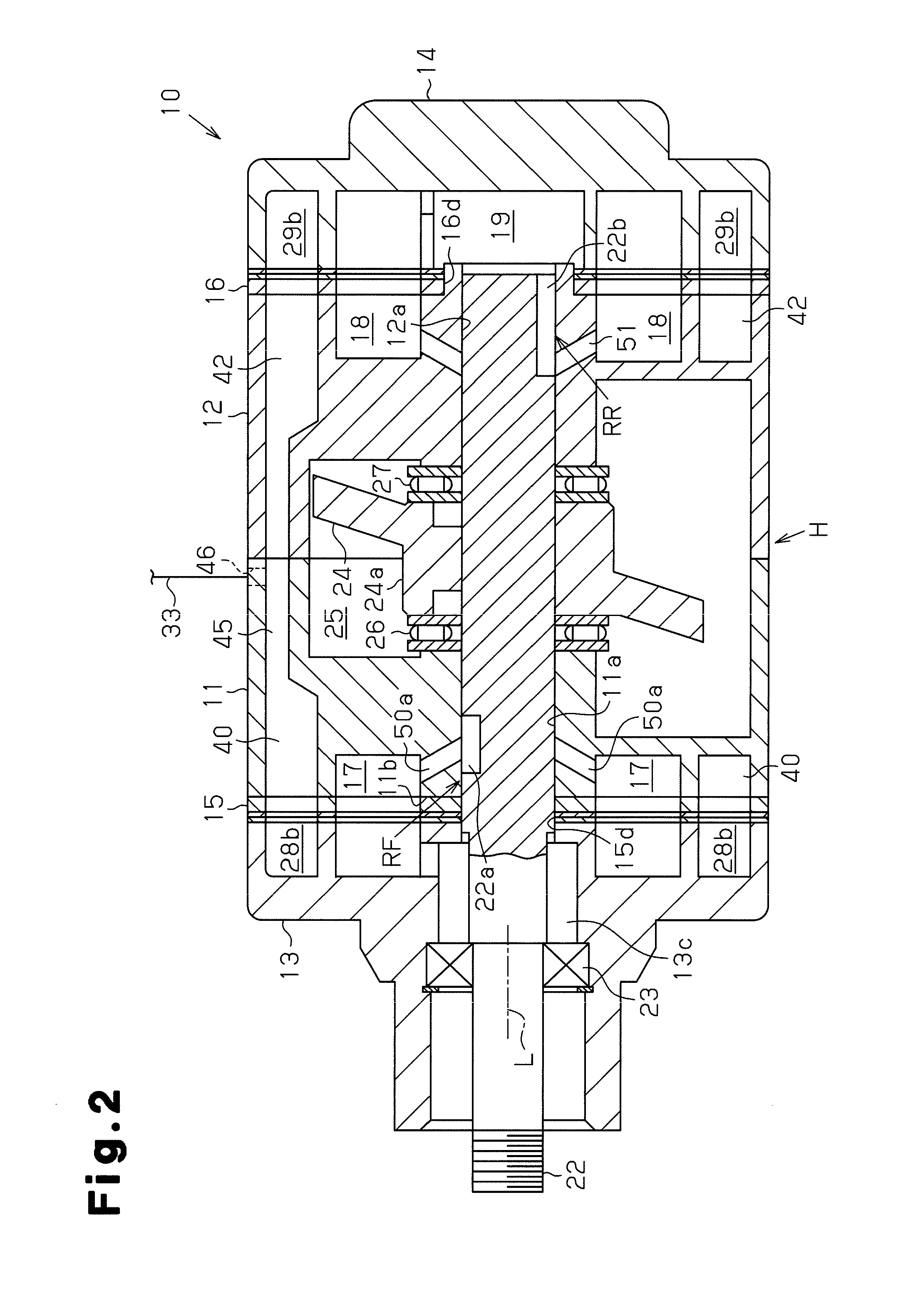

[0044]A first embodiment of the present invention that embodies a swash plate compressor in a double-headed piston type swash plate compressor 10 will now be described with reference to FIGS. 1 to 4.

[0045]As shown in FIGS. 1 and 2, a double-headed piston type swash plate compressor 10 (hereinafter simply referred to as the compressor 10) includes a housing H. A cylinder block 11, which is located at a front side (left side as viewed in FIG. 1), is coupled to a front housing 13 with a front valve / port formation body 15 arranged in between. A cylinder block 12, which is located at a rear side (right side as viewed in FIG. 1), is coupled to a rear housing 14 with a rear valve / port formation body 16 arranged in between. The housing H is formed by the two cylinder blocks 11 and 12 and the front and rear housings 13 and 14 sandwiching the cylinder blocks 11 and 12.

[0046]A rotation shaft 22 is inserted into shaft holes 11a and 12a that are respectively formed in the cylinder blocks 11 and ...

second embodiment

[0092]Next, a second embodiment of the present invention will be described with reference to FIGS. 5 to 7. The same constituents as those in the first embodiment are given the same reference numerals and overlapping description thereof is omitted or simplified.

[0093]As shown in FIGS. 5 and 7(a), a first recess 60 corresponding to each front suction chamber 17 is formed at a portion of a first end face 11b, which is a surface of a cylinder block 11 closer to a front housing 13, located outside of a shaft hole 11a. The first recess 60 is formed in the cylinder block 11 to extend from an inner wall of each front suction chamber 17 in a radial direction. One end of the first recess 60 opens toward the first end face 11b, which is a surface of the cylinder block 11 in an axial direction, and is connected with an open end of each front suction chamber 17. The other end of the first recess 60 is located in the middle of the front suction chamber 17 in the axial direction, and does not exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com