Footwear with integrated energy wave sockliner

a technology of energy wave and shoeliner, which is applied in the direction of uppers, bootlegs, stiffners, etc., can solve the problems of increasing discomfort, increasing impact force and potential discomfort of wearers, and design usually losing effectiveness, so as to improve the distribution of pressure and improve the comfort of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

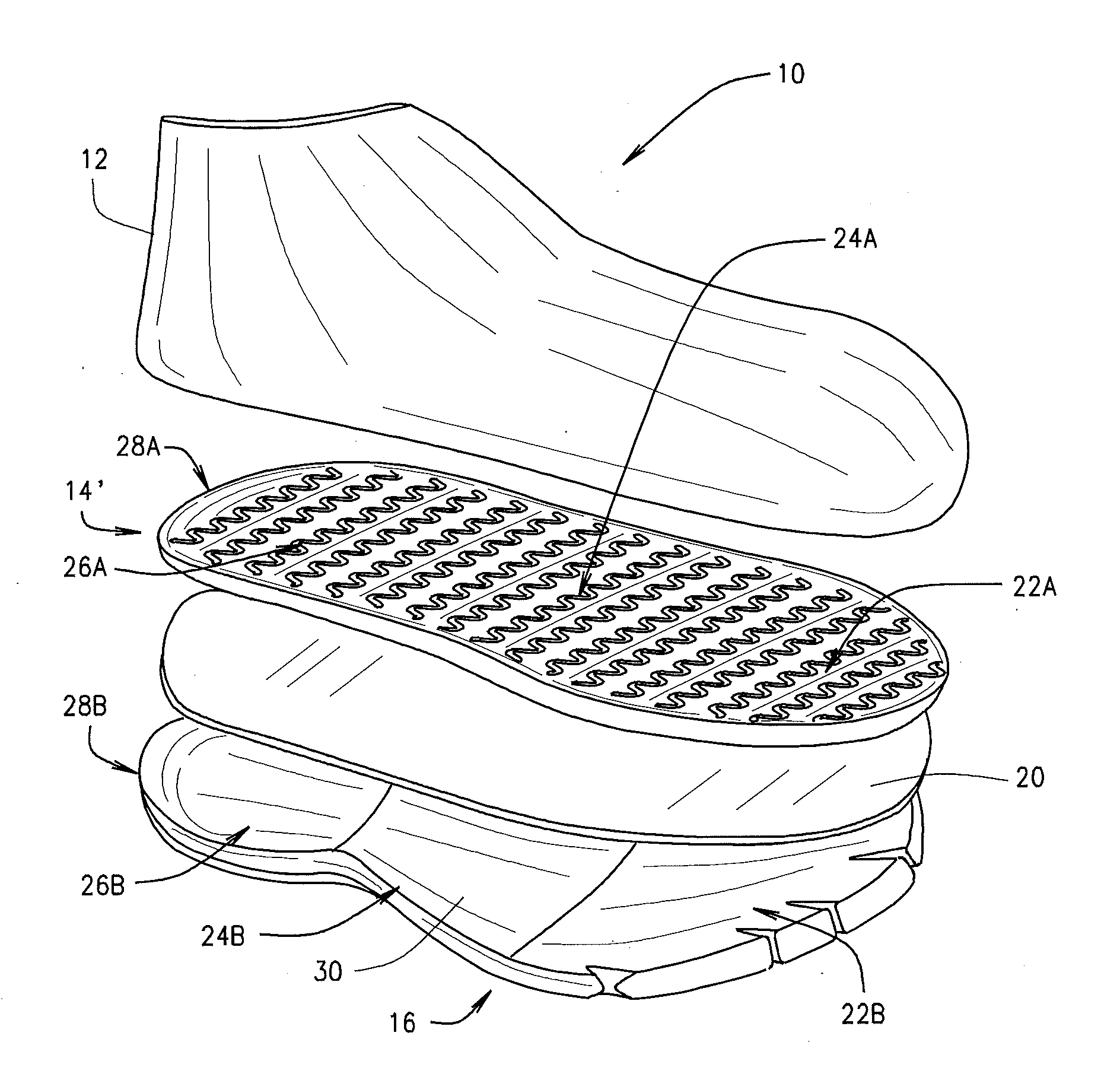

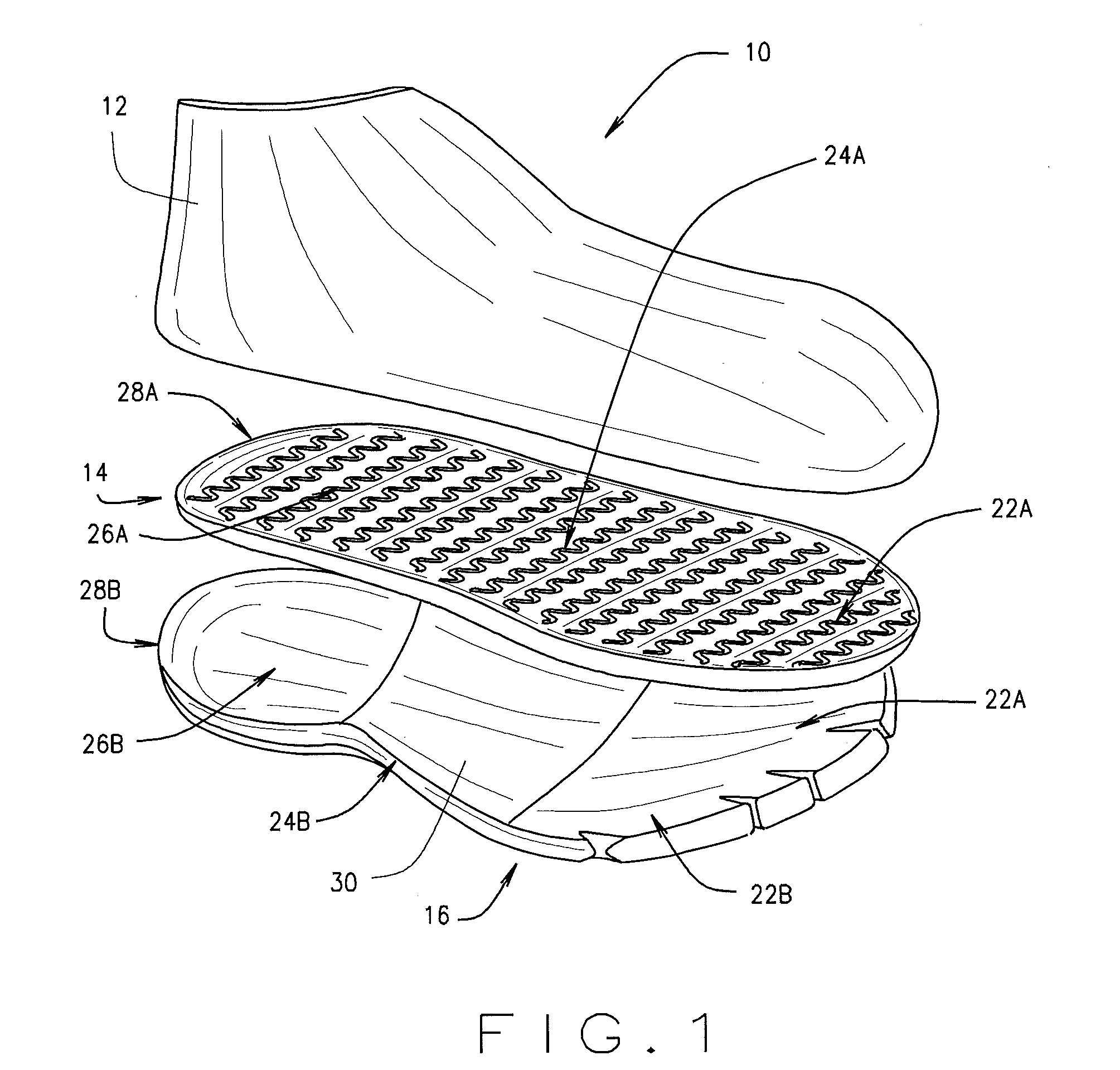

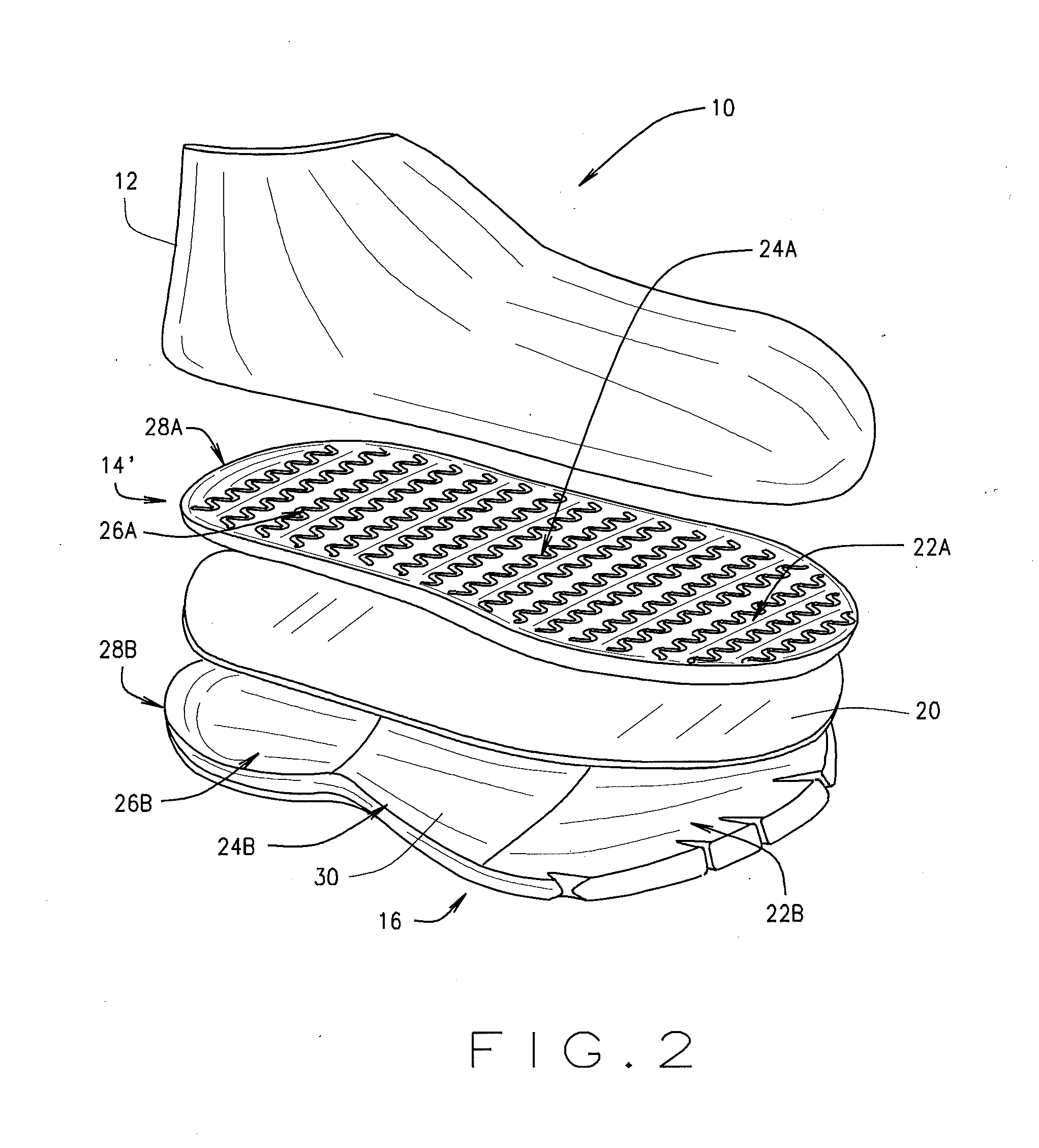

[0024]Referring now to the drawings, more particularly by reference numbers, FIG. 1 illustrates one embodiment of the shoe assembly 10 constructed in accordance with the teachings of the present invention. The present shoe assembly 10 is configured to provide improved comfort during running and other activities. The shoe assembly 10 includes an upper 12 that can be formed in any suitable style or shape, an integrated sockliner / strobel layer 14 and an outsole 16. The outsole 16 is positioned on the underside of the shoe for engagement with a walking surface such as the ground, sidewalk, floor or other supporting surface. Preferably, the top surface of the outsole 16 is shaped to conform to the bottom surface of the sockliner 14. The sockliner 14 and outsole 16 may be secured to one another using any suitable attachment means including, but not limited to, cement, adhesives, glue, welt, direct attachment constructions and the like.

[0025]For ease of reference herein, the human foot may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com