Method for Manufacturing a Laminate Product, Laminate Products Obtained Thereby and Device for Realizing the Method

a technology of laminate products and manufacturing methods, applied in the direction of controlling lamination, furniture parts, instruments, etc., can solve the problems of a certain time until it can be supplied by the printer, the laminate producer, and the little interaction between, etc., to achieve a relatively slow printing speed, a large surface area, and a large nominal passage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

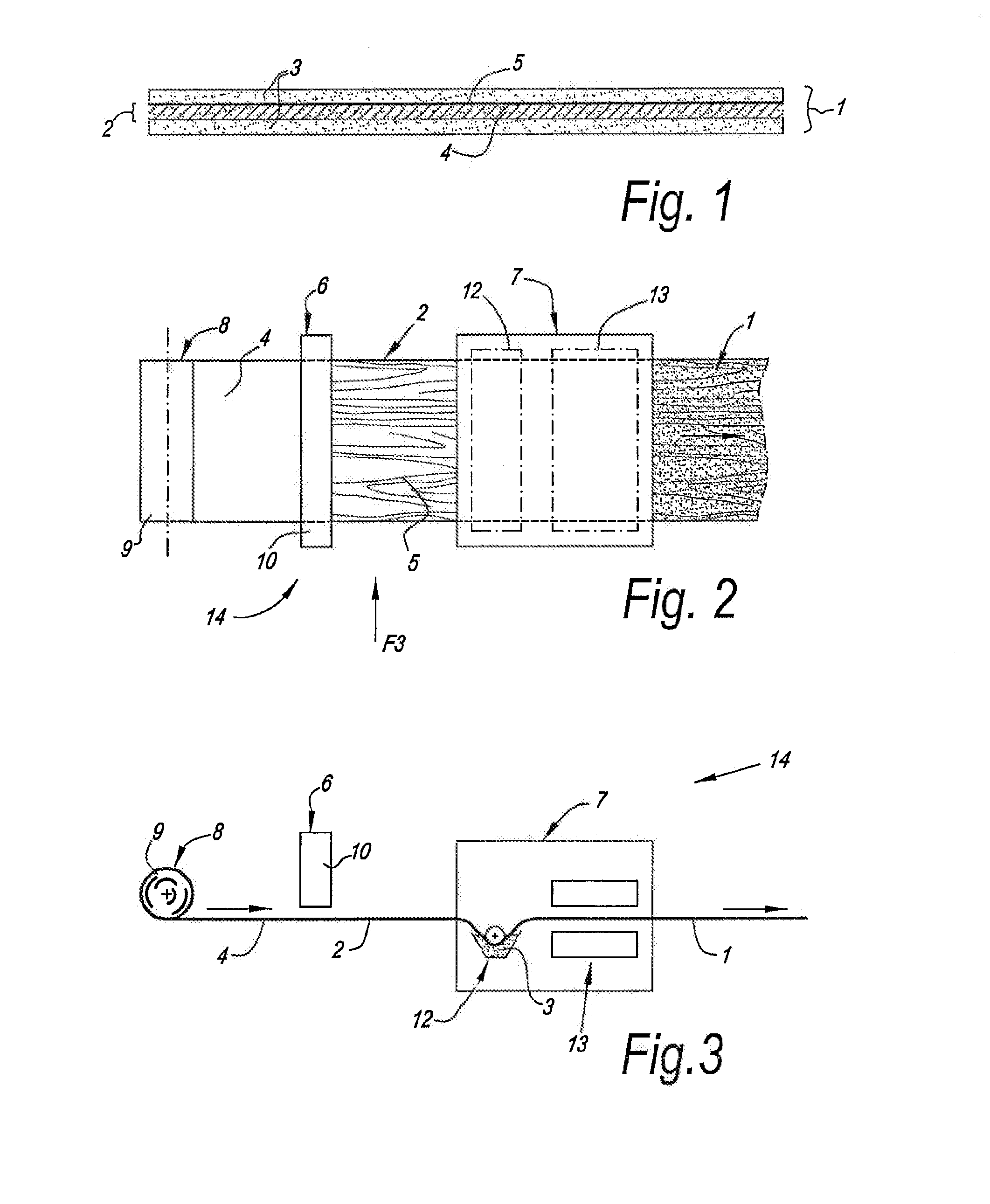

[0082]In order to illustrate the method for which the invention is intended, in FIG. 1 a laminate layer 1 is represented, which can be realized according to the invention. Herein, the laminate layer 1 consists of a decor sheet 2 provided with resin 3, wherein the decor sheet 2 in its turn at least consists of a decor carrier 4 and a decor 5 in the form of a motif carried by it.

[0083]Traditionally, the decor carrier 4 herein consists of a paper layer, whereas the decor 5 is formed by a print provided on the paper layer. However, it is clear that such decor carrier 4 and decor 5 can be build up in any manner and of any suitable material. The applied motif can be of any form. In an important application field of the invention, namely, the production of laminate floor panels, usually a motif will be applied representing wood or stone, such that by means of the installed floor panels, a parquet floor, plank floor and / or tile floor is imitated.

[0084]The resin 3 can be applied at one time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com