Variable geometry turbocharger

a turbocharger and variable geometry technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of degrading turbine efficiency, limited, difficult to achieve enhancing turbine efficiency, etc., and achieve the effect of simple structure and guaranteed stable movement of nozzle vanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

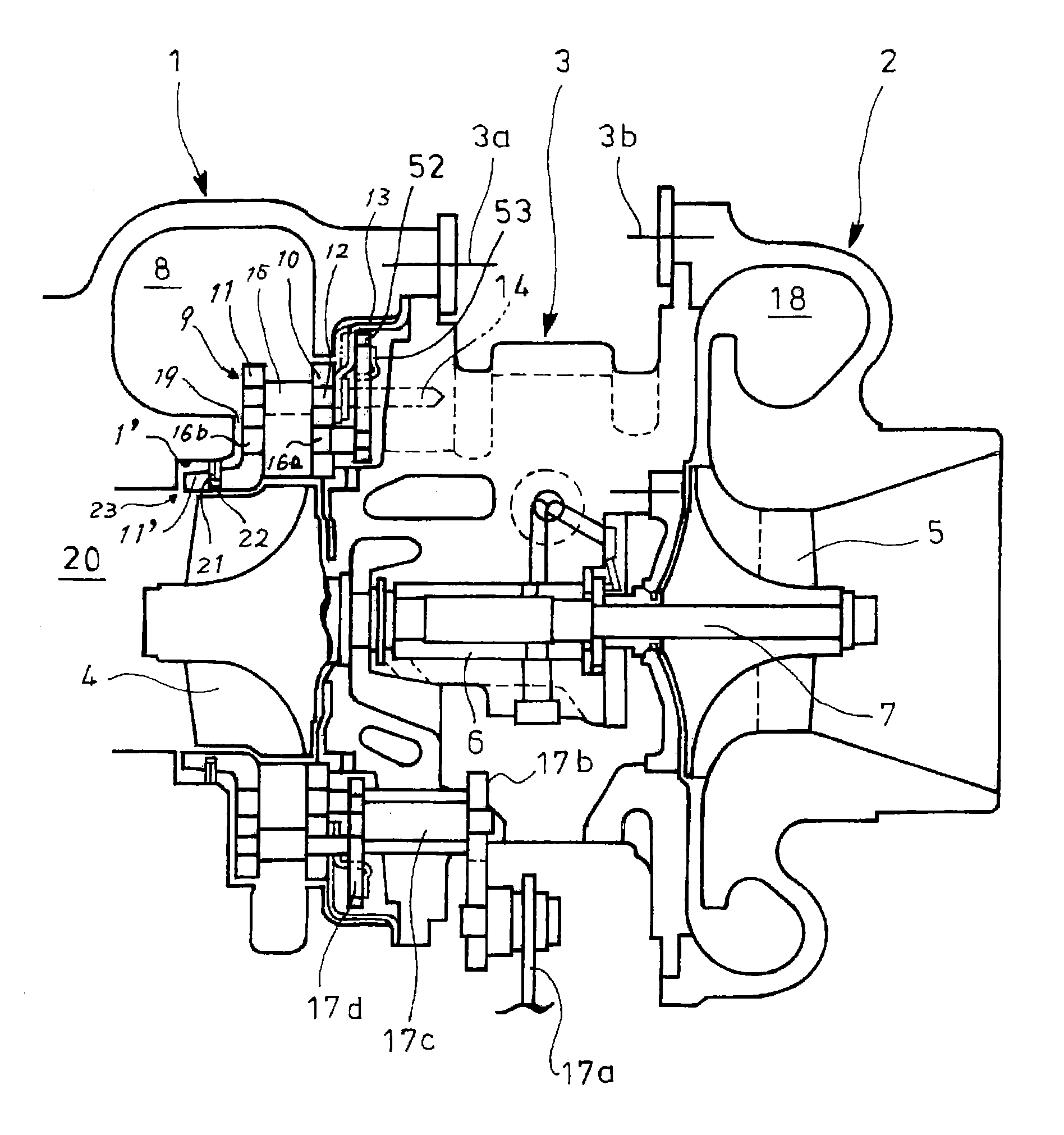

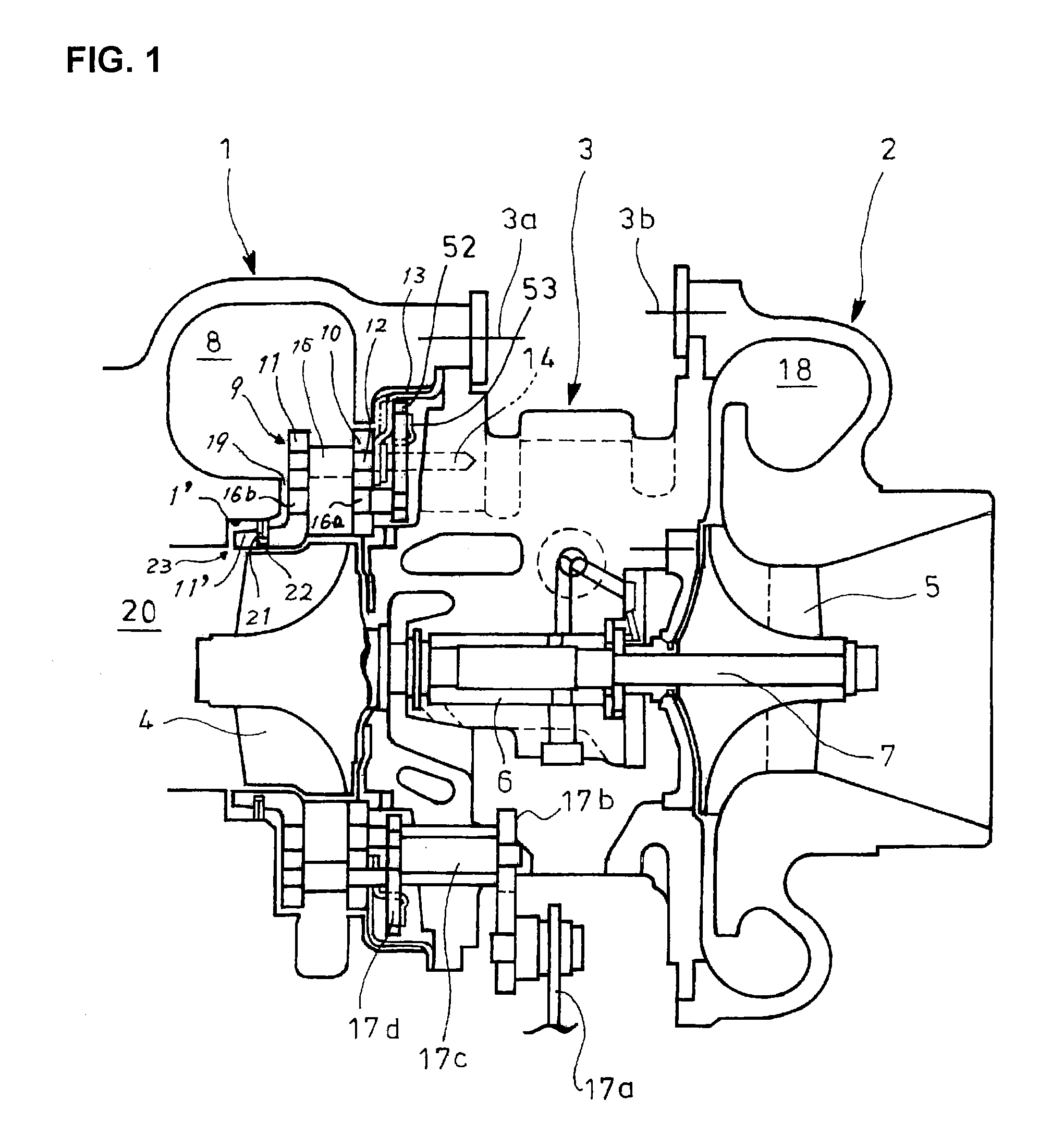

[0029]Embodiments of the invention will be described below with reference to the attached drawings.

[0030]FIG. 2 shows an embodiment of the invention in which a disk-shaped rear exhaust introduction wall 51 is substituted for the rear exhaust introduction wall 11 with the extension 11′ in the variable geometry turbocharger of FIG. 1. Thus, each of the front and rear exhaust introduction walls 10 and 51 is disk-shaped. It is preferable that the disk-shaped front and rear exhaust introduction walls 10 and 51 are made of same material or materials equivalent in linear expansion coefficient. With the rear and front exhaust introduction walls 51 and 10 set equivalent in linear expansion coefficient, the vane shafts 16a and 16b fixed to opposite sides of each nozzle vane 15 are consistently coaxially supported by the exhaust introduction walls 51 and 10.

[0031]The turbine housing 1 is formed with an extension 39 extending to a position facing to and spaced apart by a required space from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com