Golf Course Bunker

a bunker and golf course technology, applied in the field of golf course bunkers, can solve the problems of time, effort and labor, and no satisfactory solution has been developed to substantially reduce the maintenance burden of all bunkers, and achieve the effect of reducing the maintenance burden and improving the maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

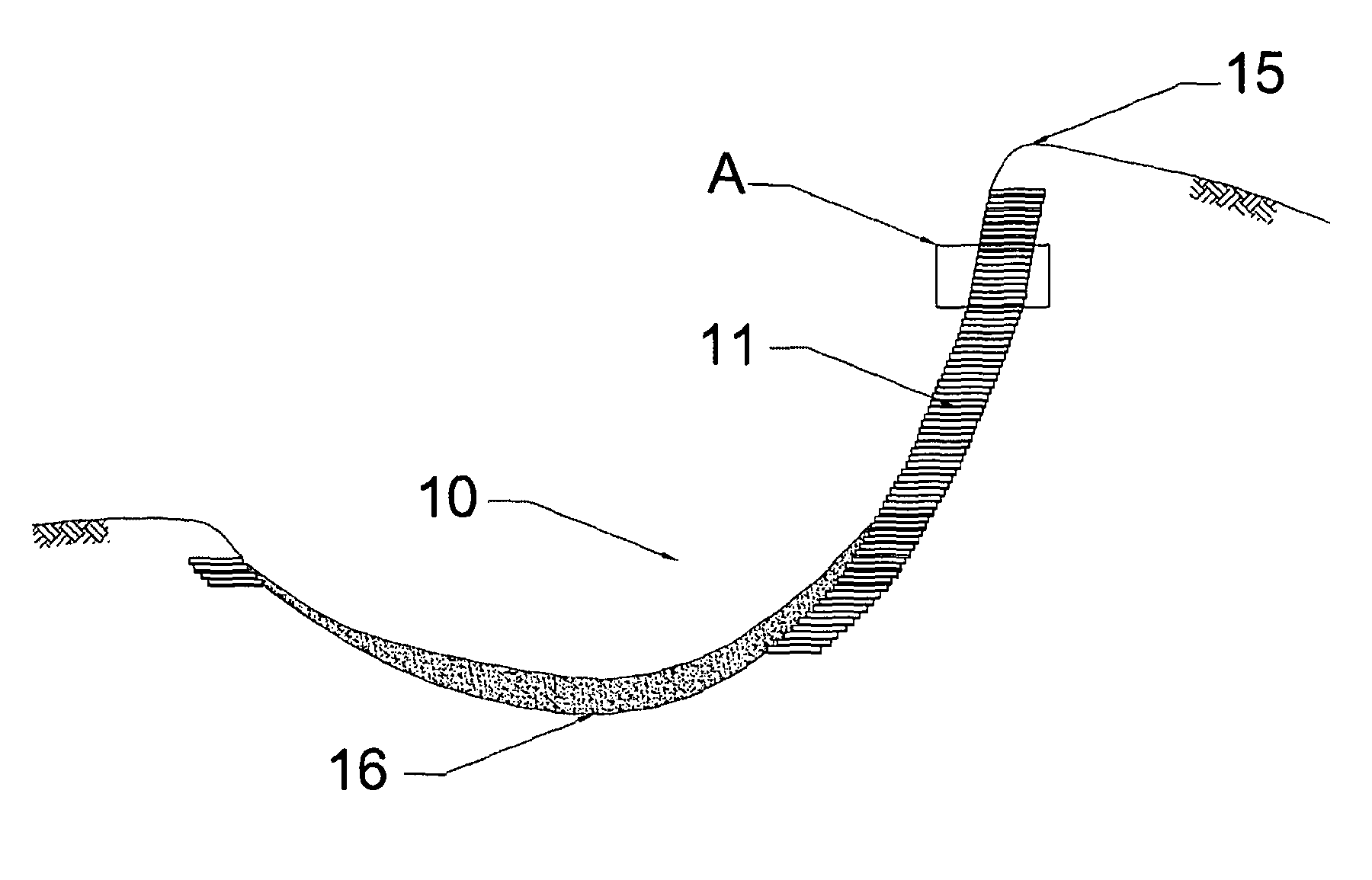

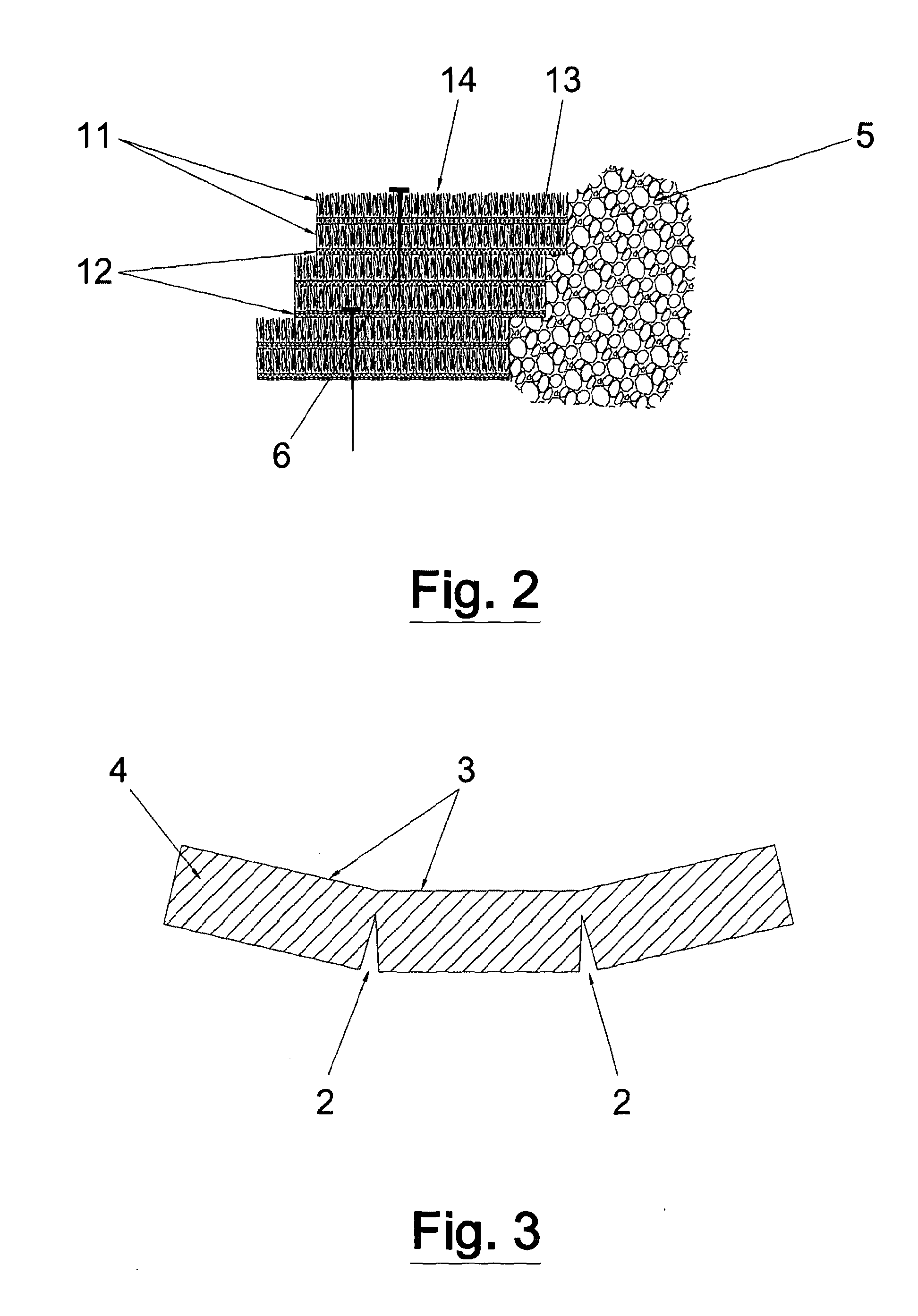

[0037]the invention is shown in FIG. 1, which illustrates in cross-section a bunker 10 on a golf course, the bunker 10 comprising a plurality of layers 11 of artificial grass. The use of artificial grass, placed in horizontal layers at a varying stagger creates a durable, low maintenance, bunker, in particular the slopes and edges of the bunker 10. In this embodiment, it is the use of artificial grass in horizontal layers 11 in forming the bunker face that makes it unique and different to any previous attempts at using artificial grass in the golfing environment.

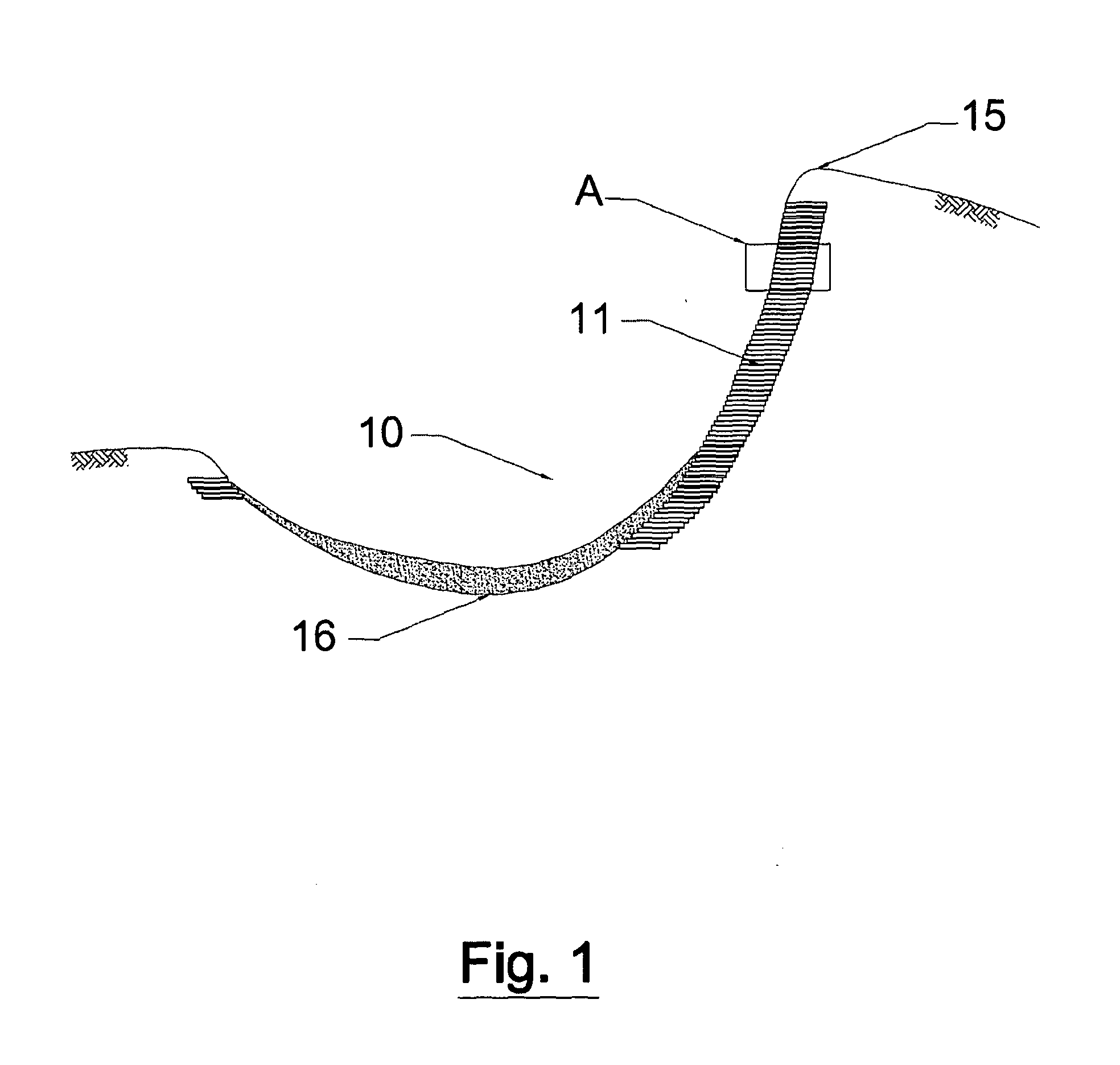

[0038]FIG. 2 shows a close-up / enlarged view of region “A” of FIG. 1. It will be seen from FIG. 2 that the at least some of the layers 11 of artificial grass are staggered, thereby defining steps 12 between at least some adjacent layers 11.

[0039]Each layer 11 of artificial grass comprises a latex backing material 13 and a polypropylene pile material 14 attached to the backing material. The depth of the pile 14 is 20 mm. The a...

second embodiment

[0045]Where bunker faces are proposed to be more than 1200 mm high, there may be a need for additional support / techniques of providing structural strength and / or integrity. Such additional support / techniques are described below with reference to the bunker of the second embodiment shown in FIGS. 4 and 5.

[0046]Ongoing maintenance may also be required. However, the maintenance of the artificial grass faces is minimal compared with traditional solutions that are formed from growing grass sod. The artificial faces are not reliant on good natural growing conditions or regular watering to keep their integrity and are much more durable to everyday wear and tear. Maintenance will be limited to occasional brushing to remove excess sand build up.

[0047]Aesthetics are very important, and the horizontal layering is critical in delivering the desired appearance. A very natural and pleasing appearance can be achieved by means of embodiments of the present invention.

[0048]FIGS. 4 and 5 show section...

third embodiment

[0049]FIG. 6 shows a bunker 210 illustrating in highly schematic form the type of 3-dimensional shape of bunker made possible by means of the present invention. Thus the bunker 210 includes a base 216 that is substantially horizontal and filled with sand, which is surrounded by a steeply sloping retaining wall defined by multiple staggered layers 211 of artificial turf. The bunker is formed as a depression in the surrounding land and thus the top region 215 of the bunker is relatively flat, and is level with the surrounding land. In this embodiment, the top region 215 is in the form of natural turf which terminates at the edge between the flat level land at the top region 215 and the steeply sloping retaining wall. In the finished bunker, the multiple layers 211 that form the side wall of the bunker are readily visible when close to the bunker, but are defined by materials such that from a distance the look and appearance of the bunker marries in well to its surroundings.

[0050]Whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com