Loudspeaker and diaphragm therefor

a technology which is applied in the field of diaphragms and loudspeakers, can solve the problems of insufficient breakup frequency of diaphragms with the geometries above, and adversely affect the sound of loudspeakers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

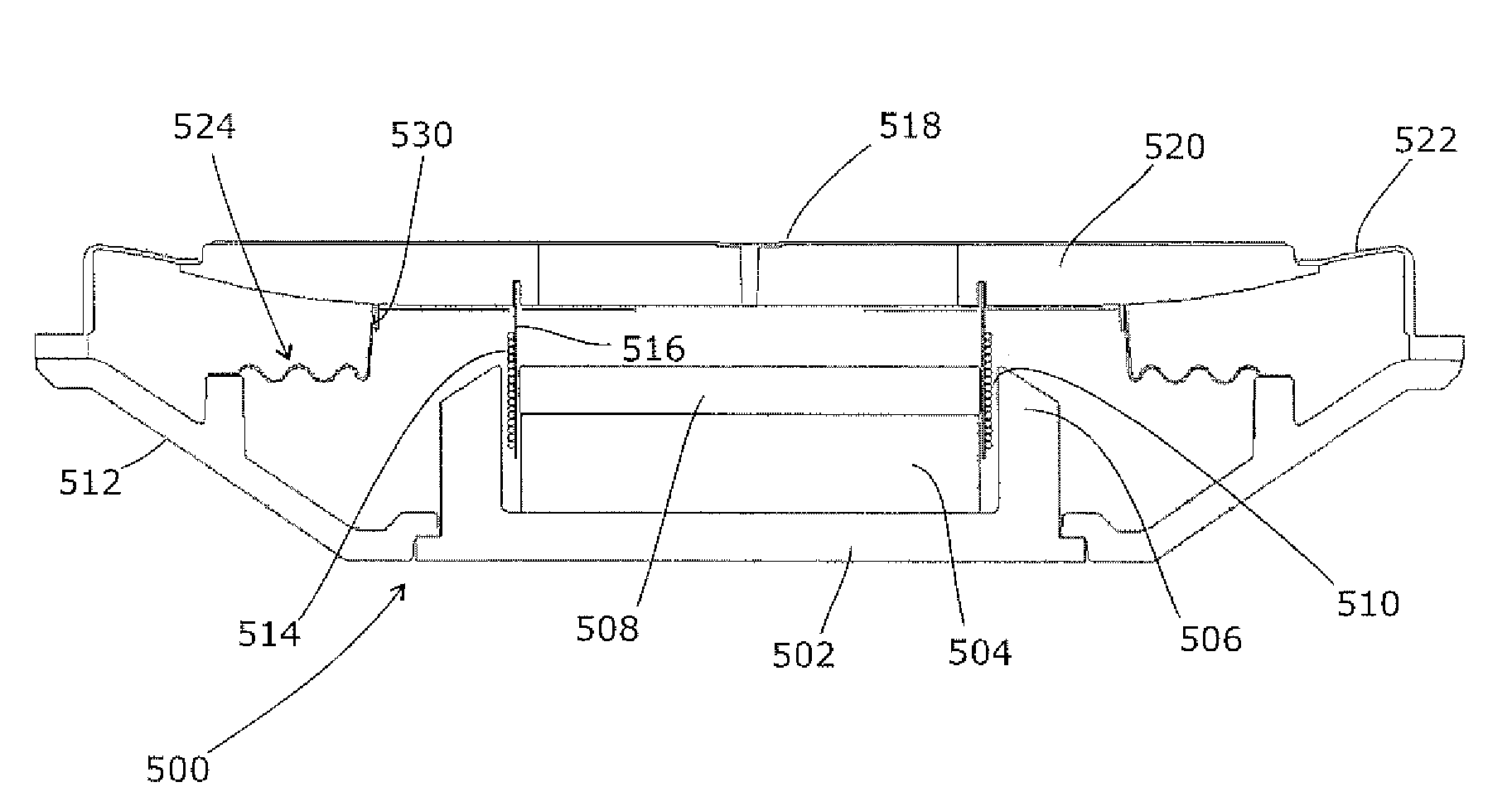

[0029]FIG. 1 shows a loudspeaker driver 500. A magnet assembly 502 carries a permanent magnet 504 and a central pole piece 508, and has a cylindrical outer pole piece 506 to define a magnetic field gap 510. A chassis 512 sits concentrically around the magnet assembly 502 and provides support for the other parts of the driver 500.

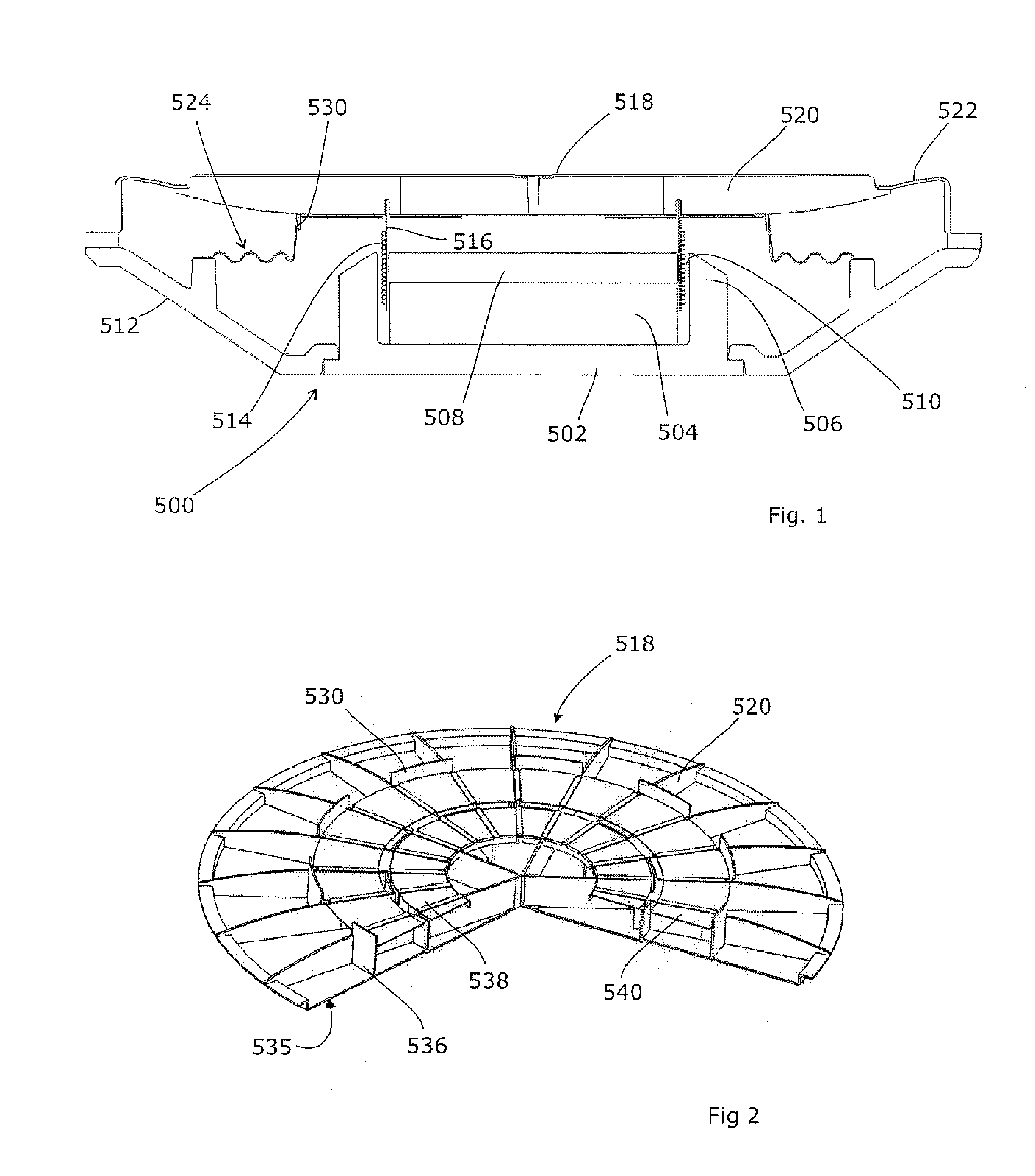

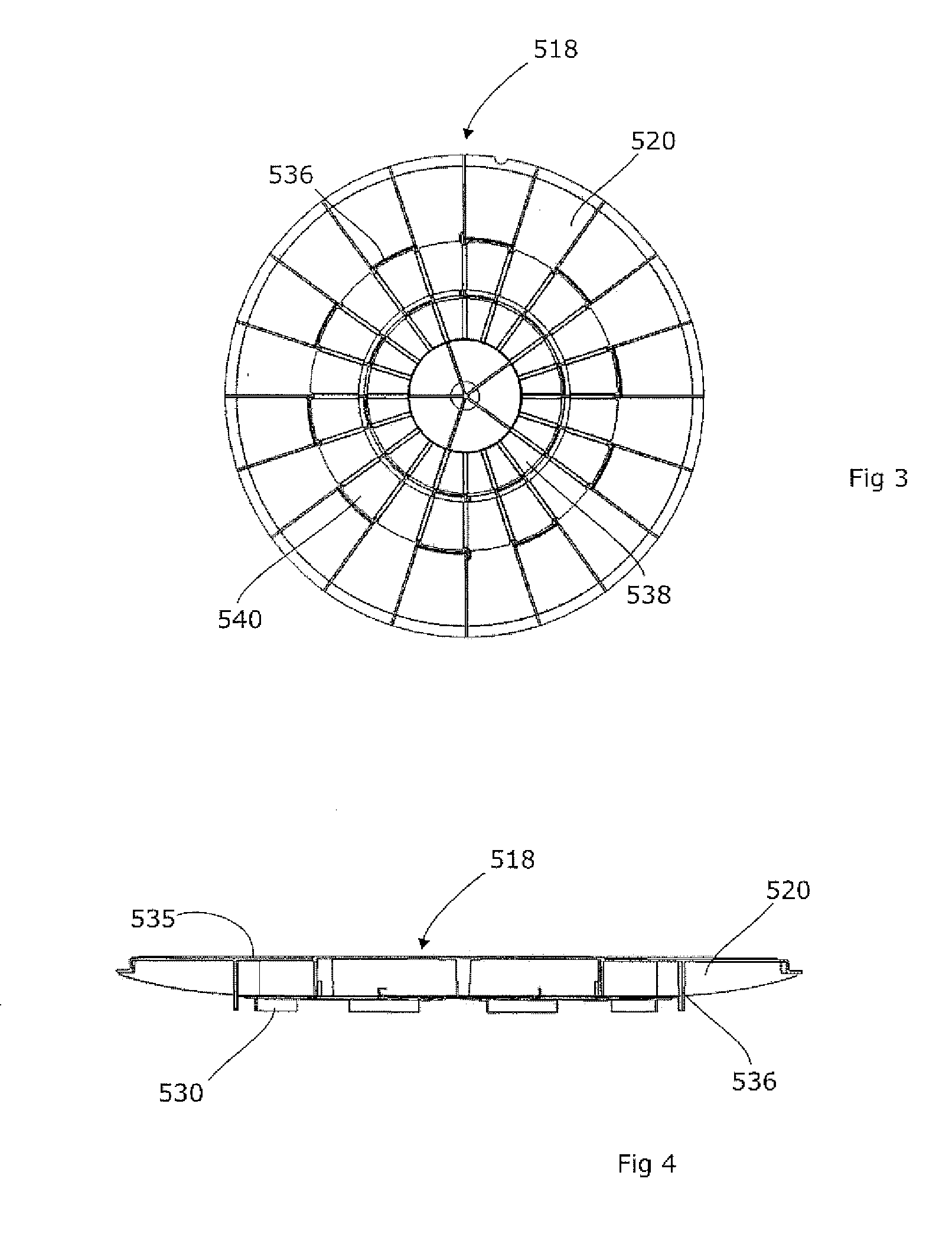

[0030]These include a voice coil 514 that is supported on a voice coil former 516 so as to lie at least partly within the magnetic field gap 510. The voice coil former 516 drives a diaphragm 518, which has a planar front surface in order to reduce the overall depth of the driver 500 as compared to a driver comprising a cone-shaped diaphragm. To provide a degree of rigidity, the diaphragm has stiffening ribs 520 on its rear face, and the voice coil former 516 is attached to these.

[0031]At its radially outermost extent, the diaphragm 518 is supported by a surround 522 which helps to centre the diaphragm 518 relative to the magnetic field gap 510, acts as an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com