Sandblasting apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

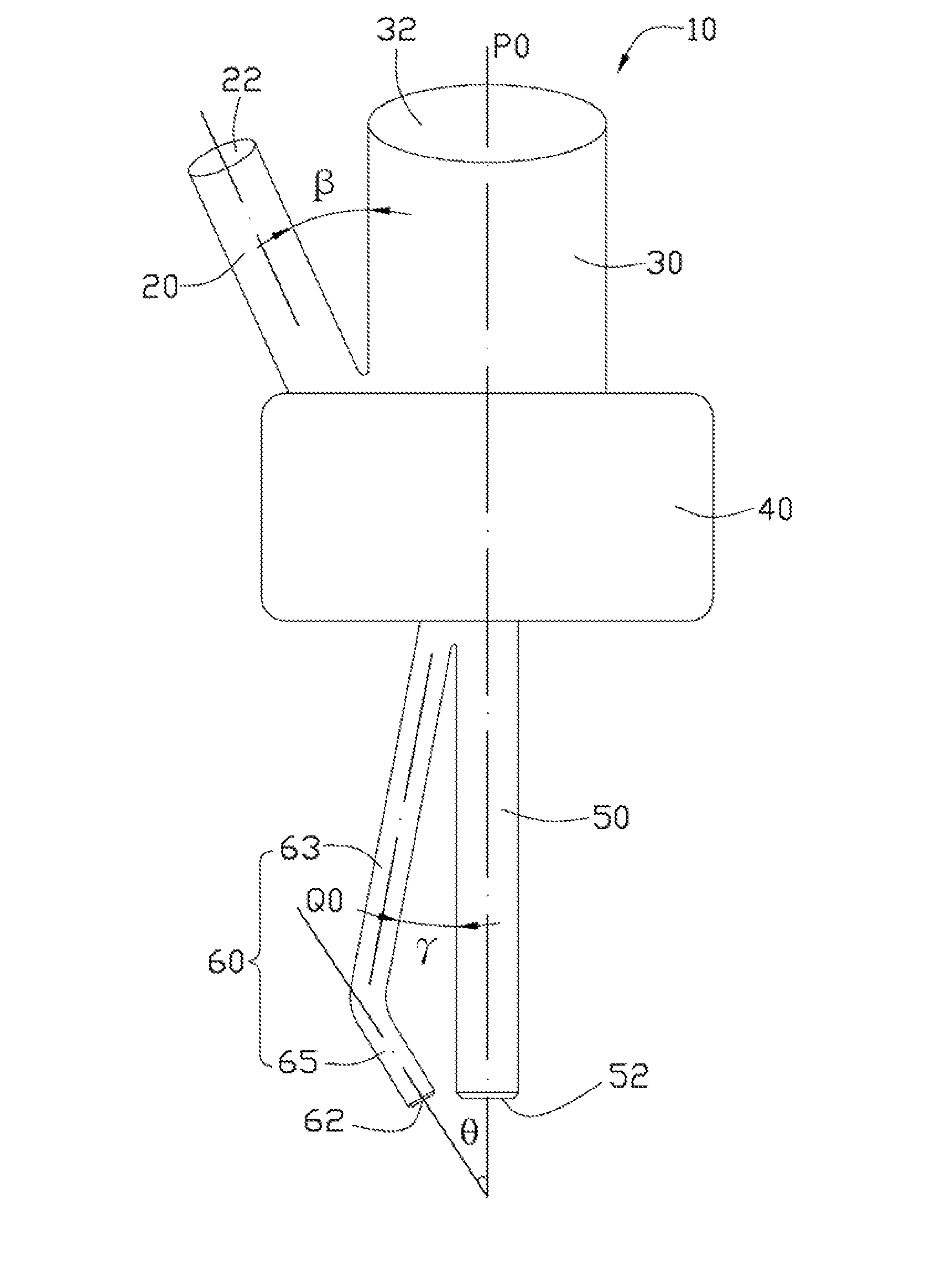

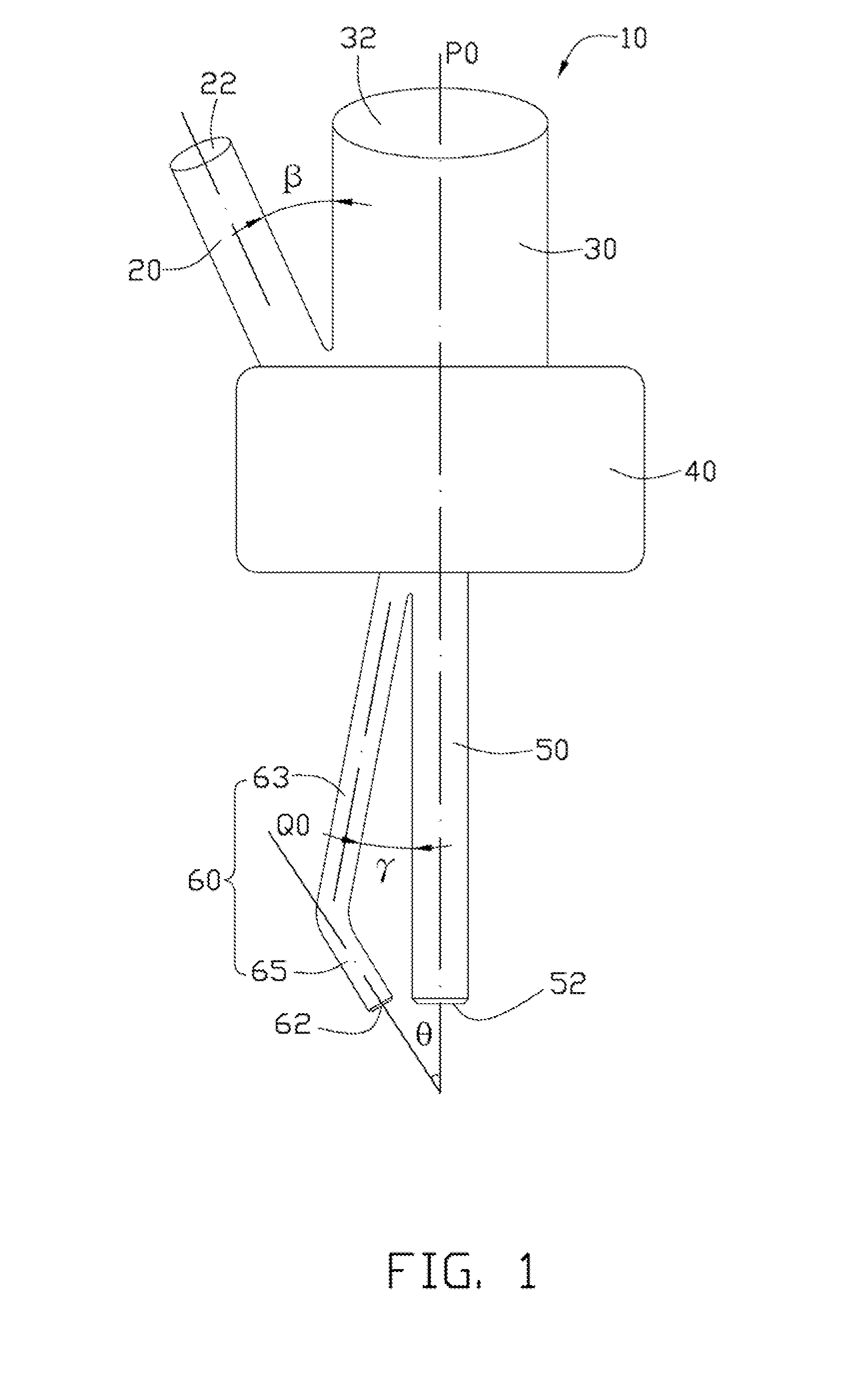

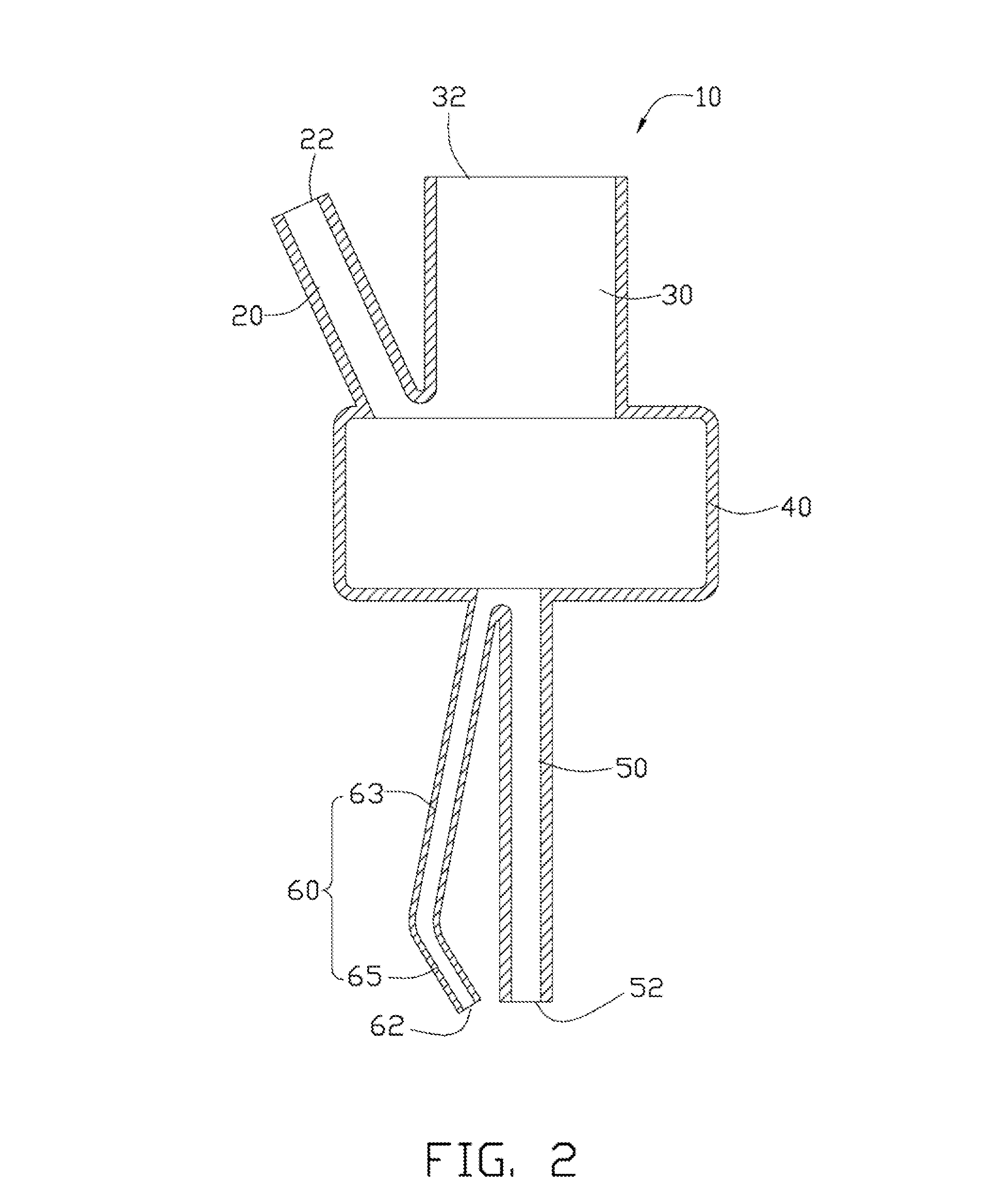

[0011]FIGS. 1 and 2 show a sandblasting apparatus 10 according to an exemplary embodiment. The sandblasting apparatus 10 may be used for removing coatings from coated articles by spraying sand particles. The sandblasting apparatus 10 includes a sand tube 20, a fluid tube 30, a mixing chamber 40, a major output tube 50 and an auxiliary output tube 60. In this embodiment, the fluid tube 30 is integrally formed with the sand tube 20. The major output tube 50 is integrally formed with the auxiliary output tube 60.

[0012]The sand tube 20 is substantially tubular and straight. The sand tube 20 defines a sand inlet 22 at one end. The sand inlet 22 may be used for inputting sand particles. Another end of the sand tube 20 connects and communicates with the mixing chamber 40.

[0013]The fluid tube 30 is substantially tubular and straight. The fluid tube 30 defines a fluid inlet 32 at one end thereof. A gaseous or liquid fluid substance, such as air or water may be input into the fluid inlet 32. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com